Rice hulling device for refined processing

A technology of fine processing and paddy, applied in grain hulling, grain processing, grain pod removal, etc., can solve the problems of high consumption of consumable parts, low rice yield, broken rice and other problems, and achieve reasonable structural design optimization, improve Separation efficiency, effect of extended milling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

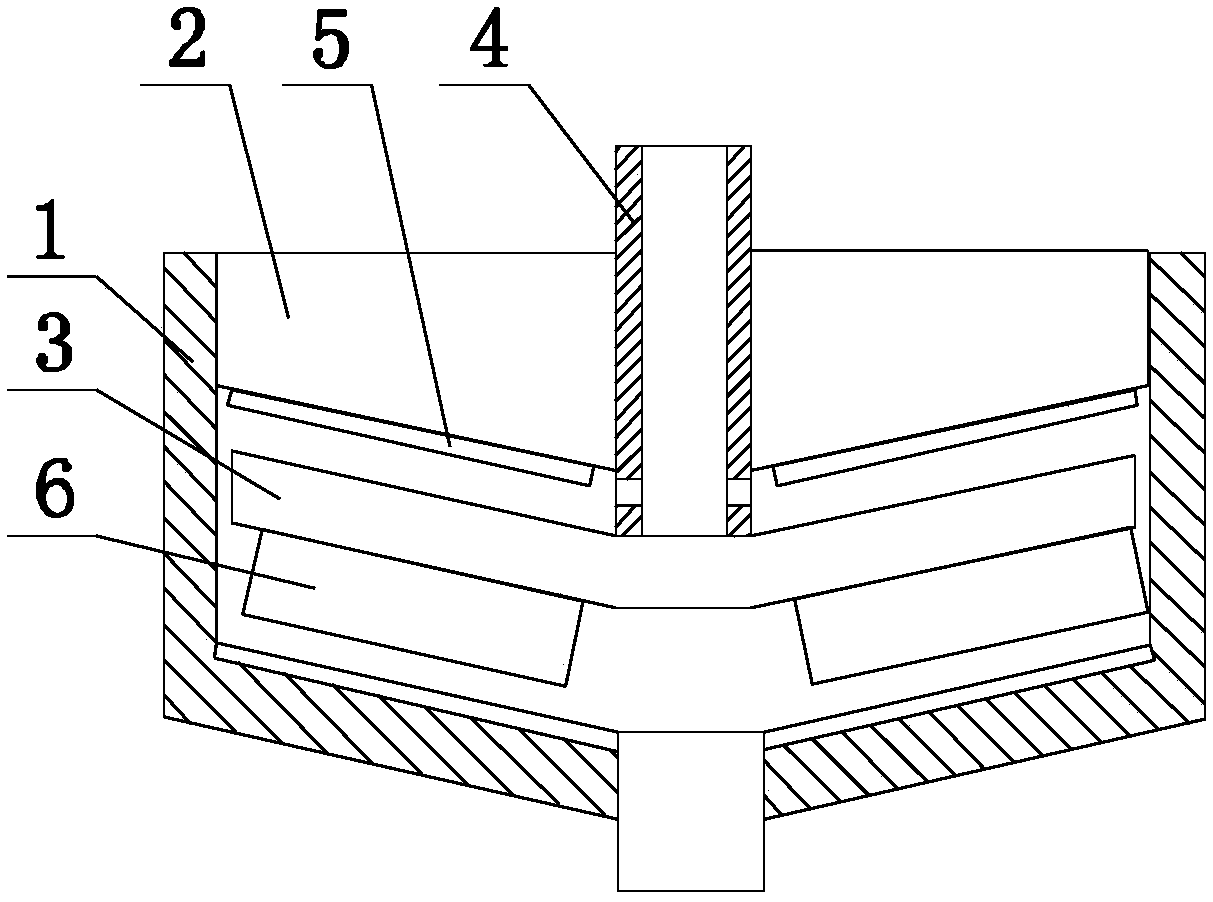

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a finely processed paddy hulling equipment proposed by the present invention.

[0015] refer to figure 1 , a finely processed paddy shelling equipment proposed by the present invention, comprising: a processing cylinder 1, a flange 2, a turntable 3, and a driving mechanism;

[0016] Inside the processing cylinder 1, there is a processing chamber with an opening at the top. The bottom of the processing chamber is provided with a discharge port. The flange 2 is horizontally arranged at the opening and fixed with the processing cylinder 1. The middle part of the flange 2 is provided with an installation opening. , the turntable 3 is located in the processing chamber, a grinding space is formed between the turntable 3 and the flange 2, the outer edge of the turntable 3 is spaced from the inner wall of the processing chamber, and a blanking gap is formed between the two, the turntable 3 The top is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com