Brush cleaning device for LCD cutting

A cleaning device and brush technology, applied in the field of LCD cleaning, can solve problems such as a lot of glass debris, abnormal circuit display, and glass debris sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

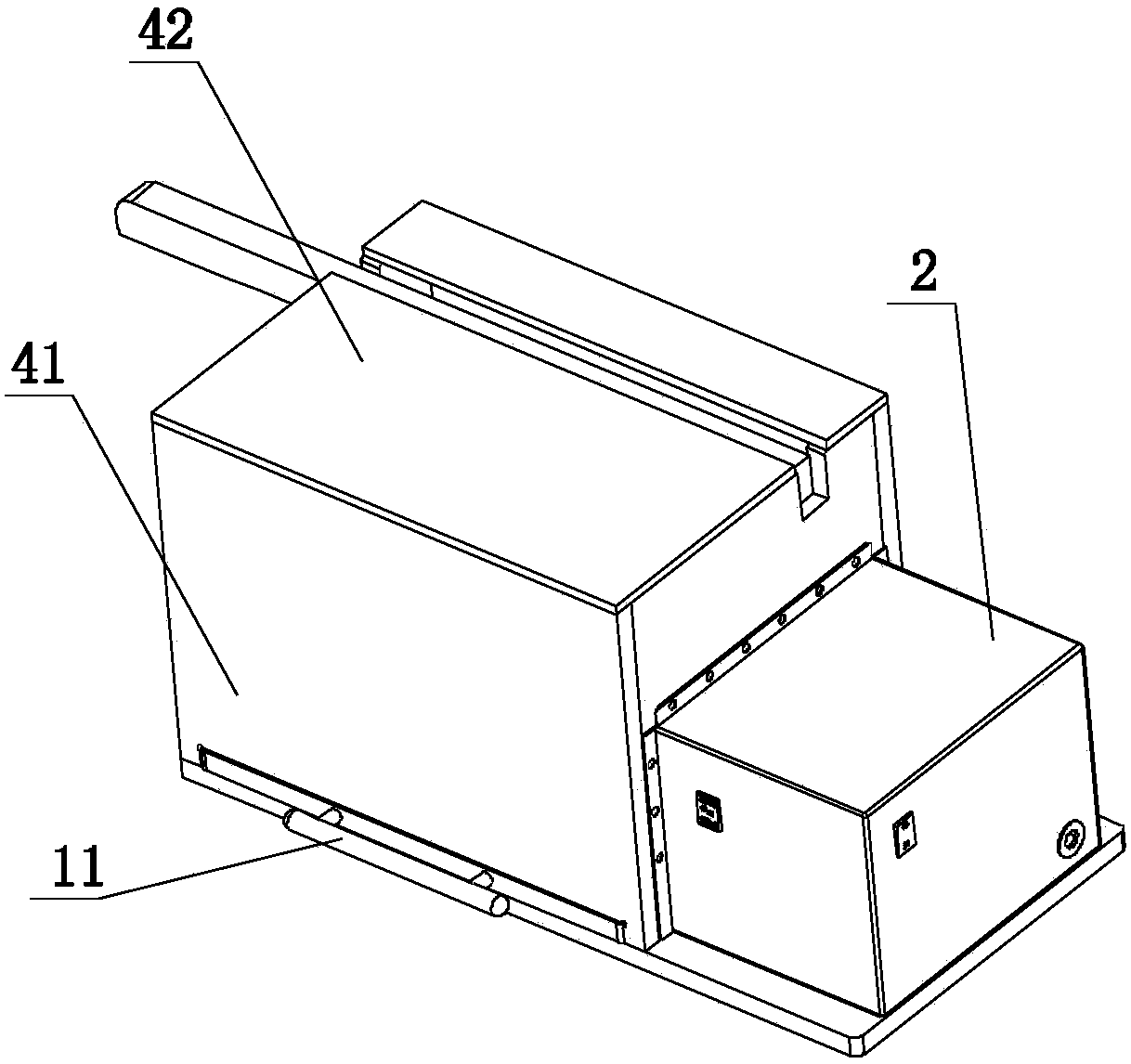

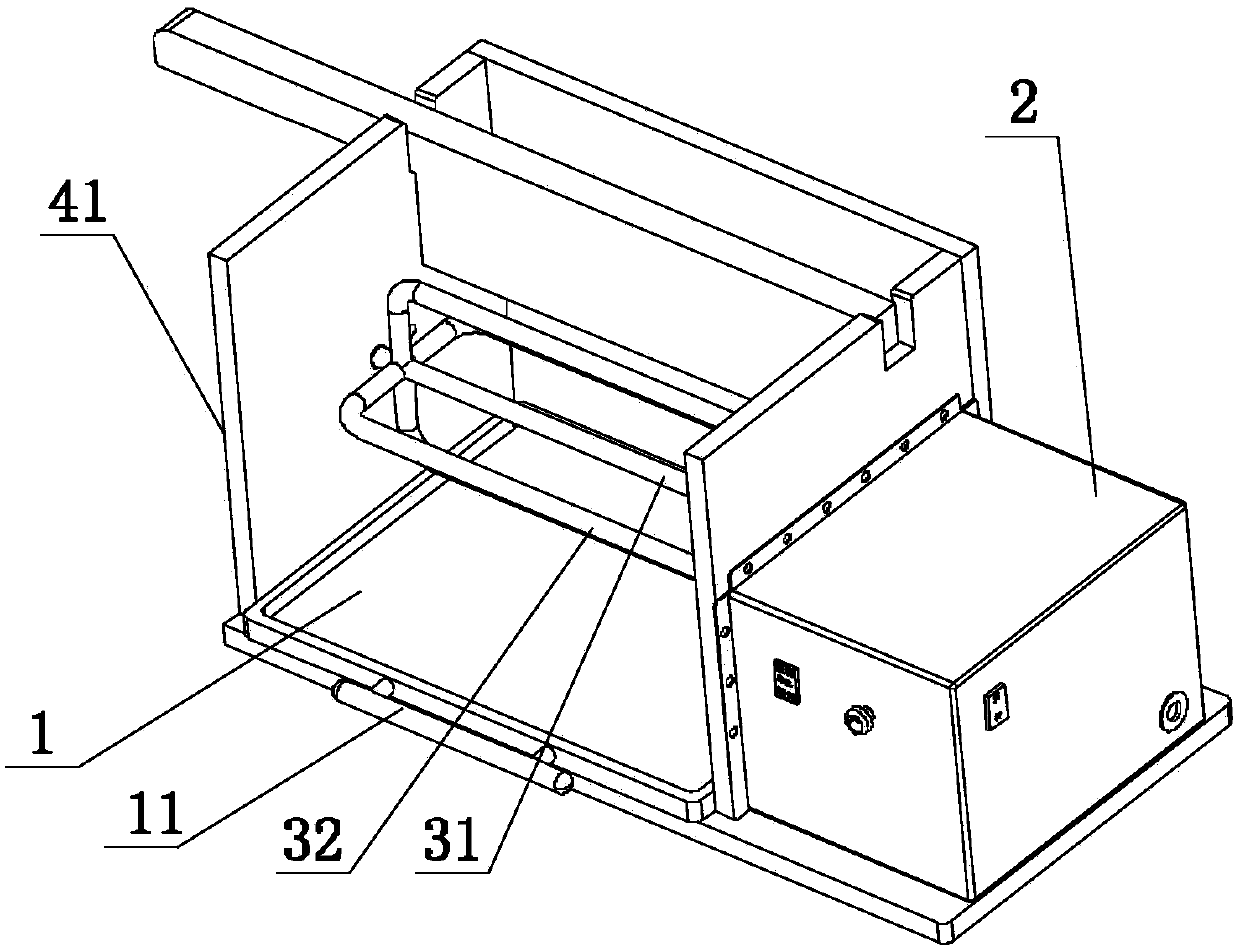

[0018] Such as figure 1 with 2 as shown, figure 1 It is a structural schematic diagram of a kind of LCD splinter brush cleaning device proposed by the present invention, figure 2 It is another structural schematic diagram of a brush cleaning device for LCD splinters proposed by the present invention.

[0019] refer to figure 1 with 2 , a kind of LCD splinter brush cleaning device that the present invention proposes, comprises: outer cover, rotating mechanism, crumb tray 1, driving motor 2;

[0020] The inside of the outer cover is provided with a cleaning chamber, the top of the outer cover is provided with a groove for placing a brush, and the side wall of the outer cover is provided with an opening for inserting the crumb tray 1, which is horizontally arranged in the cleaning chamber and can pass through the The above-mentioned opening is drawn out, and the rotating mechanism is located in the cleaning chamber and above the crumb tray 1. The rotating mechanism includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com