Magnetic photocatalyst with SPR response, and preparation method thereof

A photocatalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of long photocatalyst preparation time, small nanoparticle size, and shortened crystallization time, etc., to achieve Shortened crystallization time, small particle size, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

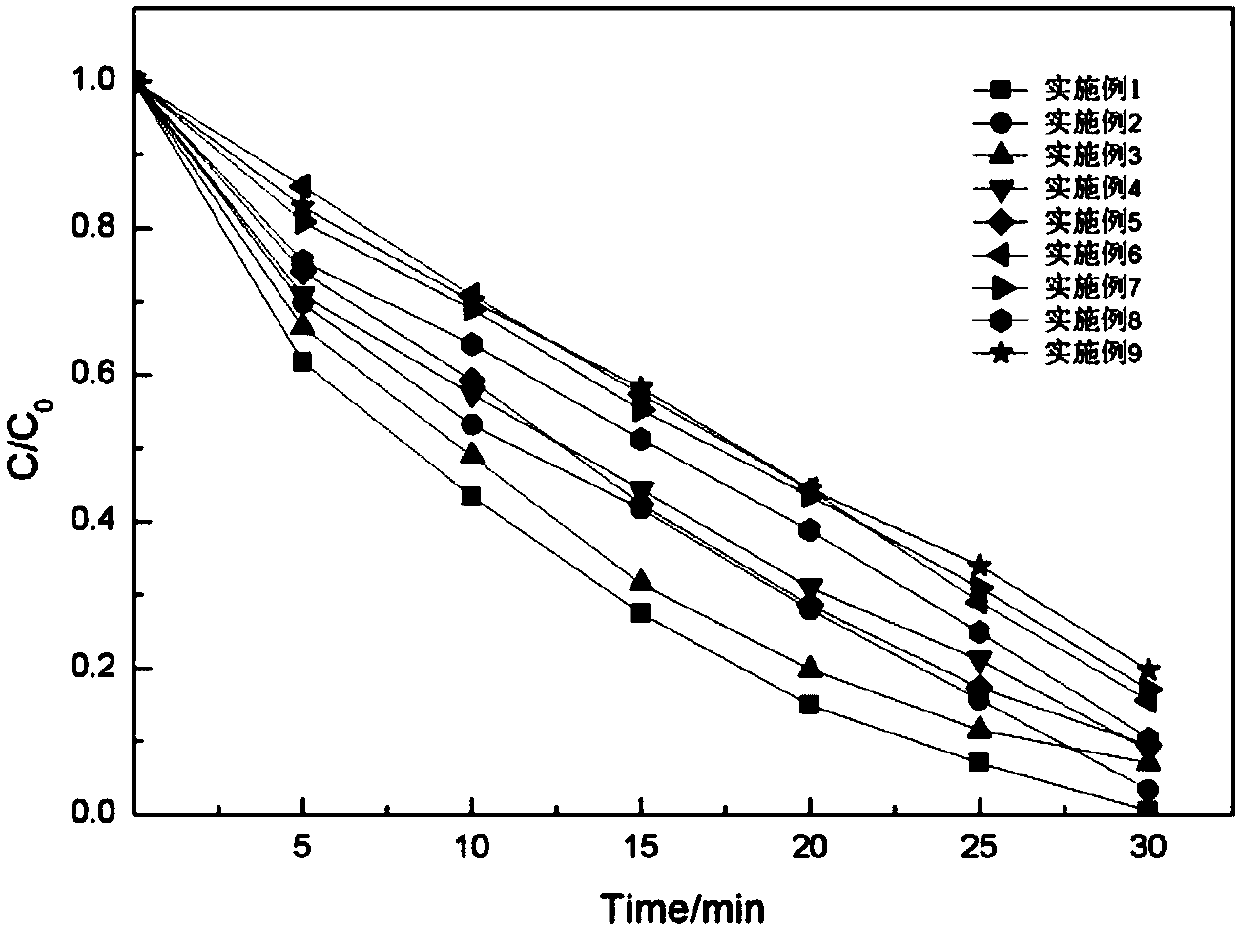

Embodiment 1

[0033] This embodiment adopts microwave-assisted synthesis to prepare Ag / Ag 3 PO 4 / Fe 3 o 4 Composite materials, including the following steps:

[0034] (1) Weigh FeCl 3 ·6H 2 O was dissolved in deionized water, and NH with a mass concentration of 28% was added under stirring 3 ·H 2 O to a pH of 9, transferred to a microwave oven and heated for 8 minutes to obtain a black precipitate; after separating the precipitate with a strong magnet, washed several times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for 6 hours. get nano Fe 3 o 4 ;

[0035] (2) the nano-Fe that step (1) obtains 3 o 4 Rapid ultrasonic dispersion in deionized water, the AgNO 3 with Na 2 HPO 4 Add to the above-mentioned dispersion liquid successively with a molar ratio of 3:1, and continue to sonicate for 50 minutes until the reaction ends; where Ag 3 PO 4 with Fe 3 o 4 The molar ratio is 1:1; after separating the precipitate in the reaction solution with a ...

Embodiment 2

[0038] This embodiment adopts microwave-assisted synthesis to prepare Ag / Ag 3 PO 4 / Fe 3 o 4 Composite materials, including the following steps:

[0039] (1) Weigh FeCl 3 ·6H 2 O was dissolved in deionized water, and NH with a mass concentration of 28% was added under stirring 3 ·H 2 O to a pH of 9, transferred to a microwave oven and heated for 8 minutes to obtain a black precipitate; after separating the precipitate with a strong magnet, washed several times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for 6 hours. get nano Fe 3 o 4 ;

[0040] (2) the nano-Fe that step (1) obtains 3 o 4 Rapid ultrasonic dispersion in deionized water, the AgNO 3 with Na 2 HPO 4 Add to the above-mentioned dispersion liquid successively with a molar ratio of 3:1, and continue to sonicate for 50 minutes until the reaction ends; where Ag 3 PO 4 with Fe 3 o 4 The molar ratio is 2:1; after separating the precipitate in the reaction solution with a ...

Embodiment 3

[0043] This embodiment adopts microwave-assisted synthesis to prepare Ag / Ag 3 PO 4 / Fe 3 o 4 Composite materials, including the following steps:

[0044] (1) Weigh FeCl 3 ·6H 2 O was dissolved in deionized water, and NH with a mass concentration of 28% was added under stirring 3 ·H 2 O to a pH of 9, transferred to a microwave oven and heated for 8 minutes to obtain a black precipitate; after separating the precipitate with a strong magnet, washed several times with deionized water and absolute ethanol, and dried in a vacuum oven at 70°C for 5 hours. get nano Fe 3 o 4 ;

[0045] (2) the nano-Fe that step (1) obtains 3 o 4 Rapid ultrasonic dispersion in deionized water, the AgNO 3 with Na 2 HPO 4 Add to the above-mentioned dispersion liquid successively with a molar ratio of 3:1, and continue to sonicate for 40 minutes until the end of the reaction; where Ag 3 PO 4 with Fe 3 o 4 The molar ratio is 1:2; after separating the precipitate in the reaction solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com