A lithium ion battery cathode slurry dispersing method

A lithium-ion battery and positive electrode slurry technology, which is applied in chemical instruments and methods, dissolution, mixers, etc., can solve the problems of poor dispersion effect, dispersion effect affecting battery capacity, battery consistency, and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

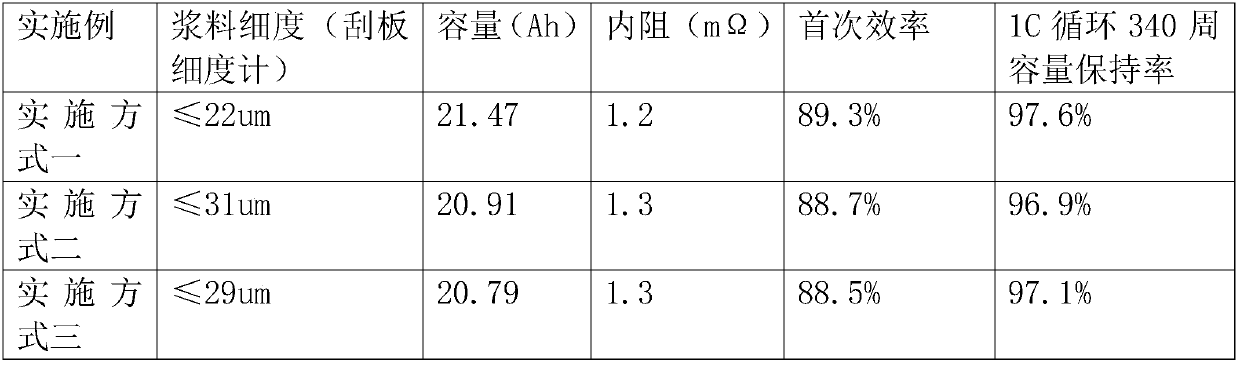

Examples

Embodiment approach 1

[0038] Include the following steps,

[0039] Step 1: Make glue, mix PVDF and NMP at a concentration of 5.5%, stir at a revolution speed of 25rpm / min, and a dispersion line speed of 12m / S for 60min;

[0040] Step 2: Stir the powder, stir the LFP and SP for 45 minutes at a revolution speed of 35 rpm / min and a dispersion line speed of 2.5 m / S.

[0041] Step 3: Stir in a muddy state, add the glue in step 1 to the mixture of LFP and SP in step 2, and adjust the solid content to 68.6% by adding NMP, at a revolution speed of 12rpm / min, and a dispersion line speed of 2.5m / s , stirred for 15 minutes, after scraping the dry material, continue to mix at a revolution speed of 32rpm / min, a dispersion line speed of 2.5m / s, and stir for 45 minutes;

[0042] Step 4: High-viscosity stirring. After adding NMP to 66% solid content in step 3, the revolution speed is 30rpm / min, and the dispersion line speed is 15m / s. Speed 21.5m / s, stirring for 45min for mixing;

[0043]Step 5: Viscosity adju...

Embodiment approach 2

[0047] Step 1: Make glue, mix PVDF and NMP at a concentration of 5.5%, stir at a revolution speed of 15rpm / min, and a dispersion line speed of 9m / S for 75min

[0048] Step 2: Stir the powder, stir the LFP and SP for 60 min at a revolution speed of 20 rpm / min and a dispersion line speed of 2.5 m / S.

[0049] Step 3: Stir in a muddy state, add the glue in step 1 to the mixture of LFP and SP in step 2, and adjust the solid content to 68.6% by adding NMP, at a revolution speed of 12rpm / min, and a dispersion line speed of 2.5m / s , stirred for 15 minutes, scraped the dry material and continued to mix at a revolution speed of 25 rpm / min and a dispersion line speed of 2.5 m / s, and stirred for 60 minutes;

[0050] Step 4: High-viscosity stirring. After adding NMP to 66% solid content in step 3, the revolution speed is 30rpm / min, the dispersion line speed is 15m / s, and after stirring for 15min, continue to revolve at a revolution speed of 40rpm / min. Speed 20m / s, stirring for 60min for...

Embodiment approach 3

[0055] Step 1: Make glue, mix PVDF and NMP at a concentration of 5.5%, stir at a revolution speed of 30rpm / min, and a dispersion line speed of 15.5m / S for 45min;

[0056] Step 2: Stir the powder, stir the LFP and SP for 30 minutes at a revolution speed of 40rpm / min and a dispersion line speed of 2.5m / S.

[0057] Step 3: Stir in a muddy state, add the glue in step 1 to the mixture of LFP and SP in step 2, and adjust the solid content to 68.6% by adding NMP, at a revolution speed of 12rpm / min, and a dispersion line speed of 2.5m / s , stirred for 15 minutes, scraped the dry material and continued to mix at a revolution speed of 40rpm / min, a dispersion line speed of 2.5m / s, and stirred for 30 minutes;

[0058] Step 4: High-viscosity stirring, after continuing to add NMP to 66% solid content in step 3, at a revolution speed of 30rpm / min, a dispersion line speed of 15m / s, after mixing for 15min, continue at a revolution speed of 50rpm / min, the dispersion line Speed 23m / s, stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com