Automatic air blowing and filtering system applied to air inlets of transportation tools

A technology for transportation vehicles and air inlets, which is applied to the field of blasting during the operation of rail transportation vehicles and road transportation vehicles, which can solve problems such as blockage and reduction of air intake, and achieve high dust removal efficiency, load reduction, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

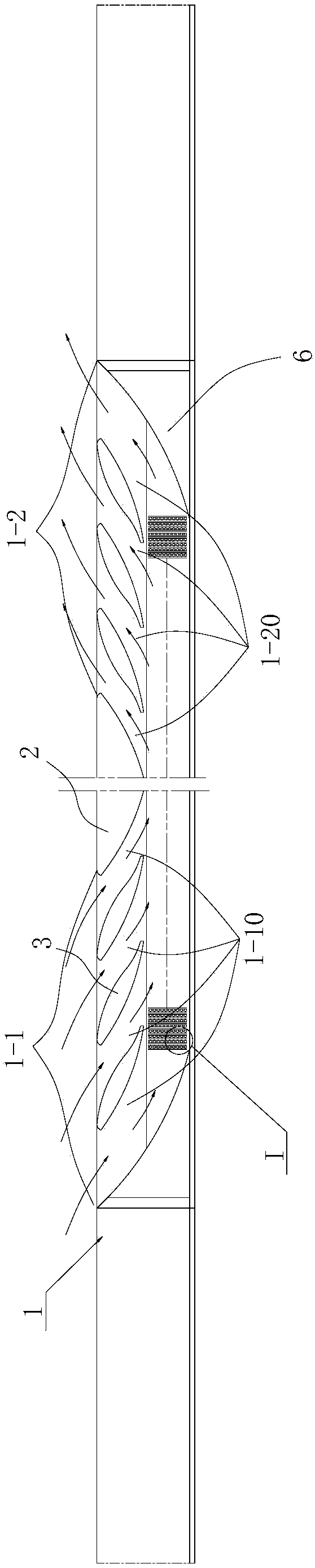

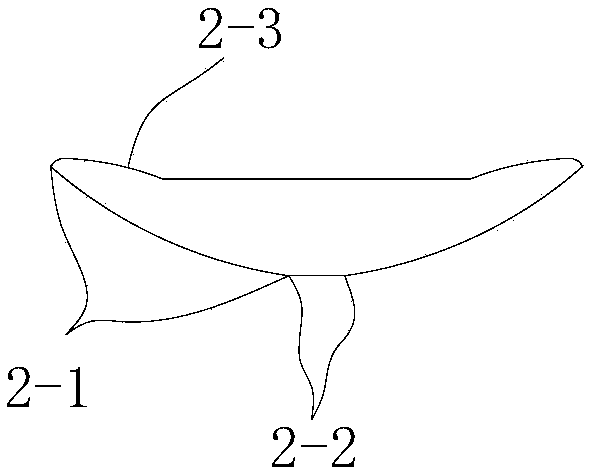

[0045] Example 1, see Figure 1 to Figure 2 , Figure 3 to Figure 7 , an automatic blower air filter system for the air inlet of a transport tool, comprising an air filter frame 1 installed on the dust removal port of a rail transport tool, one side of the filter air frame is provided with a filter air inlet 1-1, the filter air The other side of the air frame is the filter air outlet 1-2, and an intermediate guide body 2 is set between the filter air inlet and the air outlet; the two sides of the intermediate guide are respectively provided with an intermediate air inlet guide surface 2-1 , the lower ends of the two intermediate air intake guide surfaces are connected to the main air duct guide surface 2-2; in order to ensure the double-sided air intake of the device, the intermediate guide body is provided with two intermediate air intake guide surfaces; The tuyere becomes an air outlet to allow the floating objects to be discharged smoothly. The external diversion angle and...

Embodiment 2

[0059] Example 2, see image 3 and Figure 9 , the upper end of the guide body increases step by step toward the intermediate guide body. In this embodiment, the upper part of the intermediate guide body is symmetrically provided with an external guide surface 2-3. All the other structures are the same as in Example 1.

Embodiment 3

[0060] Example 3, see Figure 10 , the two ends of the air filter frame are provided with end drains 6 . According to different technical environments, the shape and angle of the end drainage body are different; the shape can be flat or curved; the angle formed with the extension of the device is determined by the flow rate of the external air flow; the principle is to ensure as much as possible of the outside world The airflow is introduced into the air inlet of the device, and at the same time, the separation between the airflow and the drainage surface is reduced, and the generation of vortex is reduced.

[0061] The surface of the device is coated with a super nano-hydrophobic coating. This coating greatly reduces the adhesion on the surface of the airflow channel; when the high-speed rail EMU is operating under heavy snow conditions, the snowflakes cannot be bonded to the surface in the airway, and are quickly discharged back into the atmosphere. Therefore, in snowy wea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com