Experimental device and method for accurately calculating hydrate content change in small volume sediments

A hydrate, small-volume technology, used in analytical materials, instruments, etc., can solve the problems of difficult to control hydrate saturation, large measurement errors, and insignificant increase in gas pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

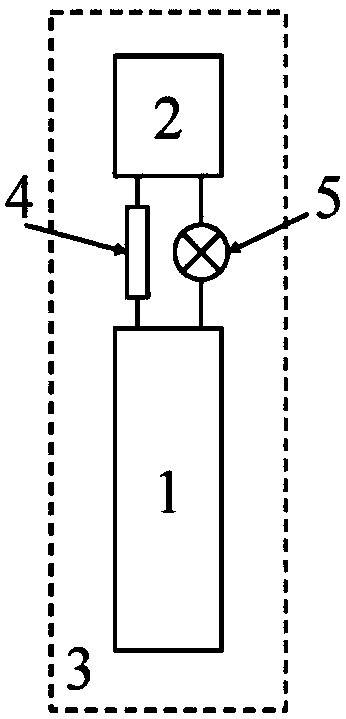

[0034] Such as figure 1 As shown, a small-volume reactor with an effective volume of no more than 10ml is used as an example. It is an experimental device for accurately measuring the change of hydrate content in small-volume sediments. It consists of a small-volume reactor, a standard gas chamber, and a resolution of no more than 1kPa. It consists of a differential pressure sensor and a temperature control module. The small-volume reactor is connected to the standard gas chamber, and a stop valve is arranged between the two; the two ends of the differential pressure sensor are connected to the small-volume reactor and the standard gas chamber to measure the gas pressure difference between the two; the small-volume reaction The kettle, the standard gas chamber and the differential pressure sensor are all placed in the temperature control module to control the temperature of the three to be the same and constant.

Embodiment 2

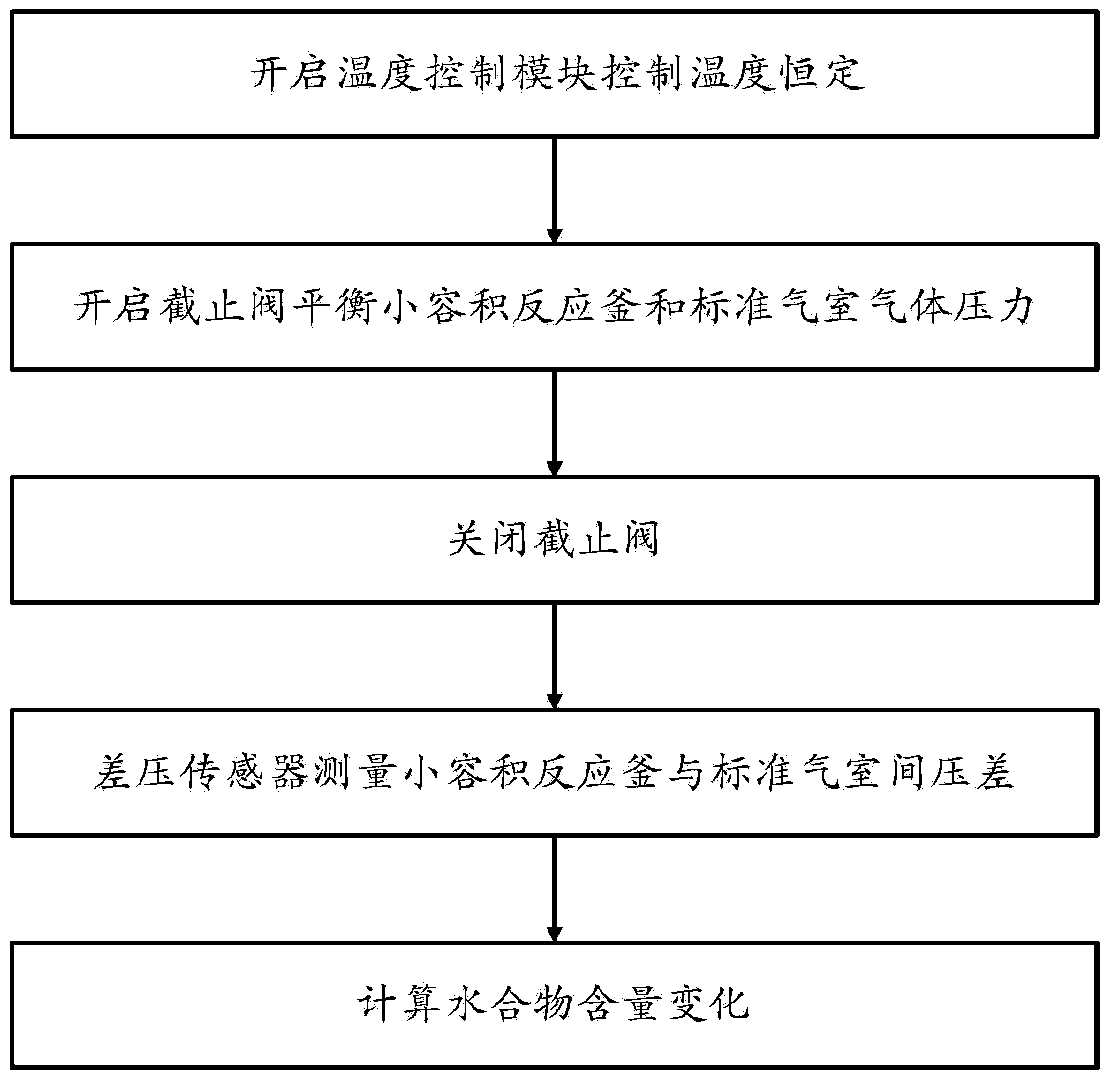

[0036] Based on the above experimental setup, the figure 2 As shown, an experimental method for accurately measuring and calculating the change of hydrate content in small-volume sediments provided by the present invention specifically includes the following steps:

[0037] (1) Open the temperature control module to keep the temperature of the small volume reactor and the standard gas chamber the same and constant;

[0038] (2) Open the stop valve to connect the small volume reactor and the standard gas chamber to balance the gas pressure of the two;

[0039] (3) Close the shut-off valve to isolate the small-volume reactor from the standard gas chamber. The pressure of the small-volume reactor will decrease due to hydrate synthesis and increase due to hydrate decomposition, while the standard gas chamber pressure will not change;

[0040] (4) A differential pressure sensor is used to measure the pressure difference between the small-volume reactor and the standard gas chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com