Bagasse drying equipment

A drying equipment and bagasse technology, applied in biomass drying, drying solid materials, drying gas layout and other directions, can solve problems such as uneven drying, fermentation and taste, bagasse pretreatment, etc., to improve dehydration efficiency, material particle uniformity, The effect of accelerating drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

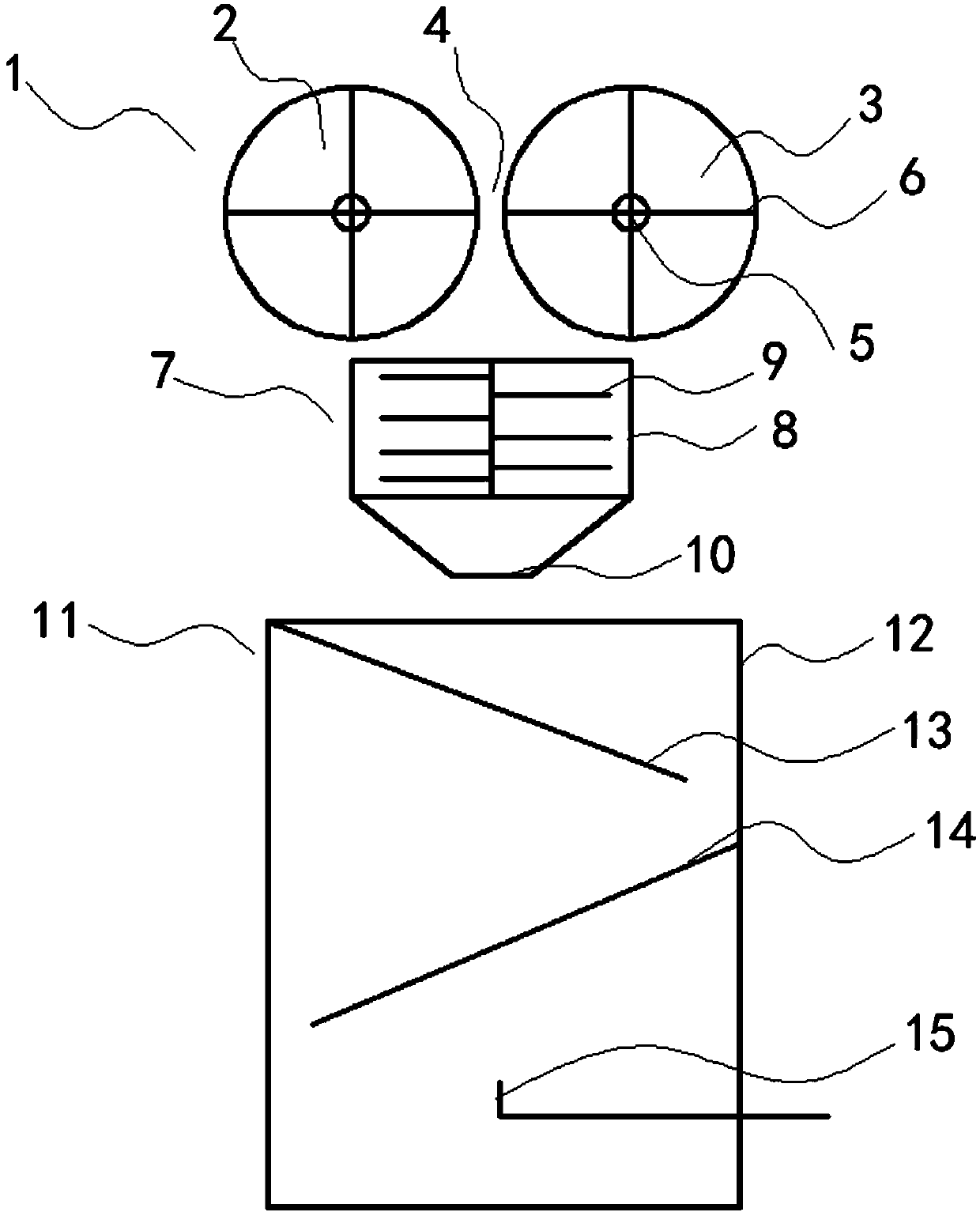

[0031] Such as figure 1 , 2 Shown in and 3, a kind of bagasse drying equipment comprises:

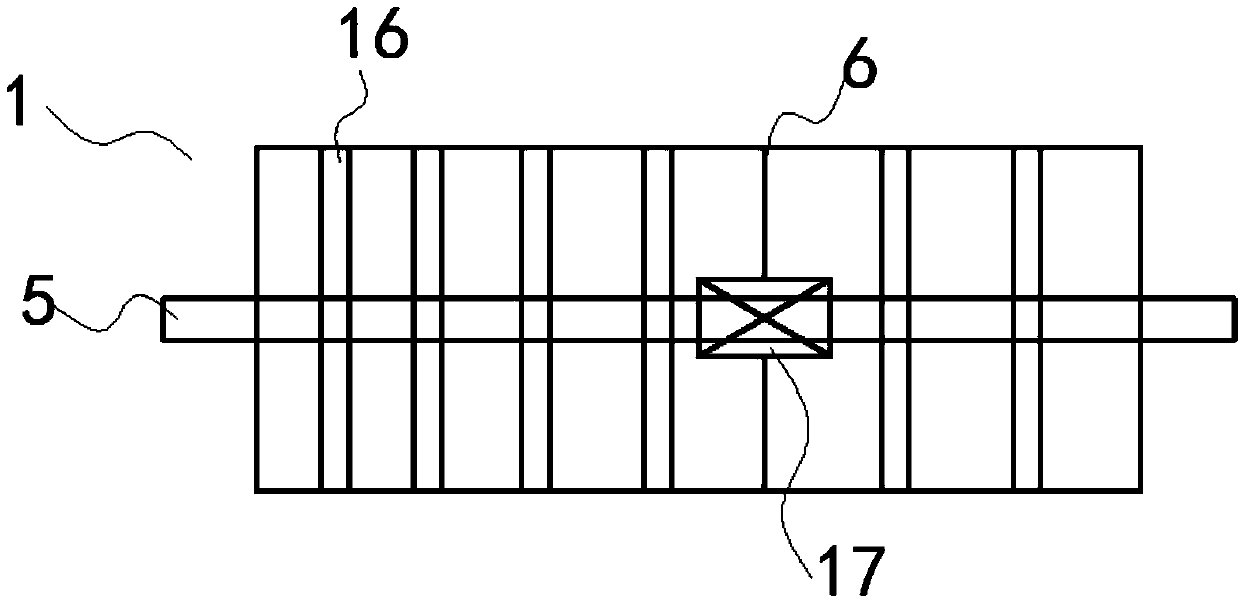

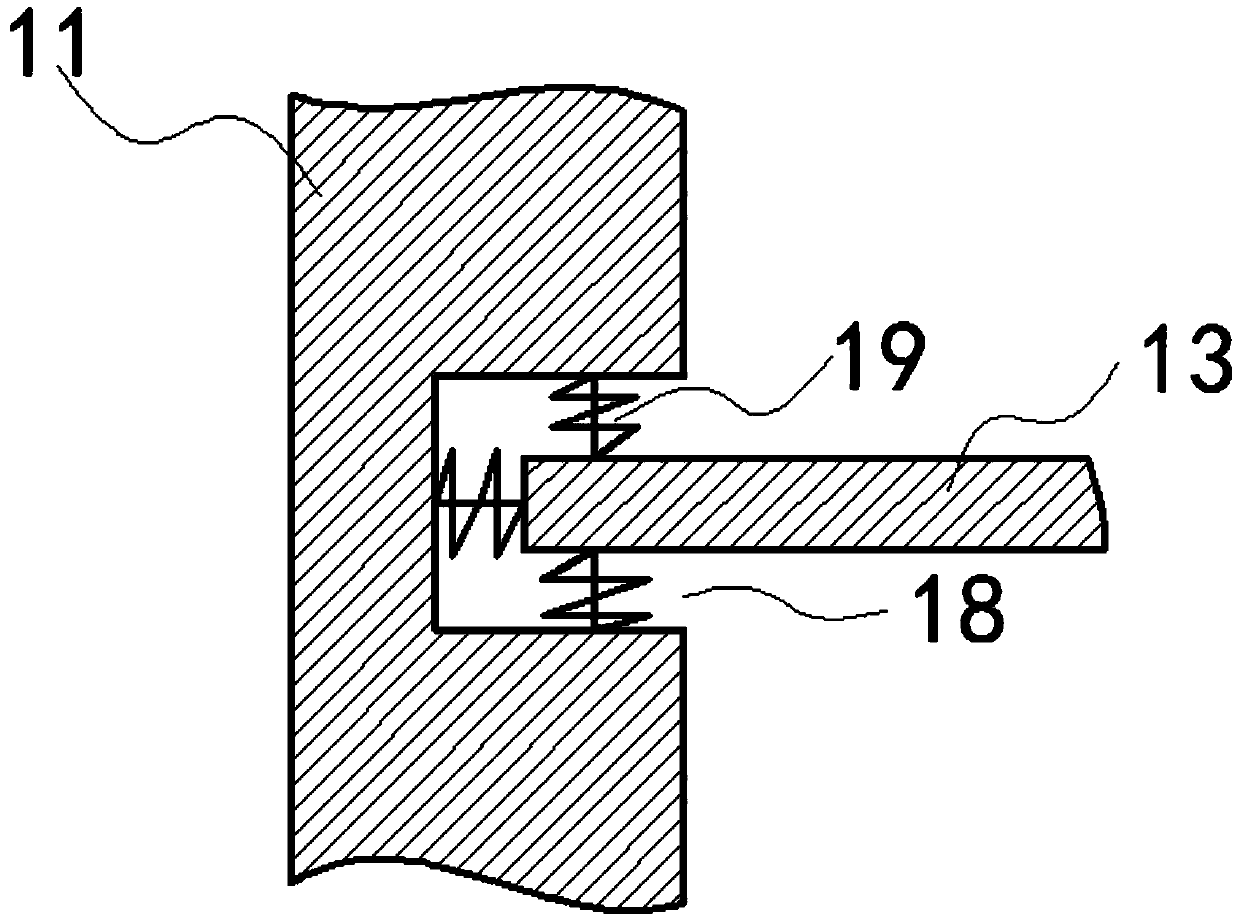

[0032] Dehydration device 1, which includes a rolling unit and a suction unit arranged inside the rolling unit, the rolling unit includes a first roller 2 and a second roller 3 of equal size, the first roller 2 and the second roller 3 are parallel to each other and on the same horizontal line, there is a first gap 4 for rolling materials between the first roller 2 and the second roller 3, and the first and second rollers have the same structure, the first roller and the second roller include a hollow cylinder, circular end plates arranged at both ends of the cylinder, and a central shaft 5 passing through the cylinder and through the center of the end plate , wherein, the end plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com