Preparation method and application of hollow mesoporous structure NiCoS polyhedron

A technology of mesoporous structure and polyhedron, which is applied in the field of preparation of hollow mesoporous structure NiCoS polyhedron, can solve the problems of poor activity and high cost of electrocatalyst, and achieve high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

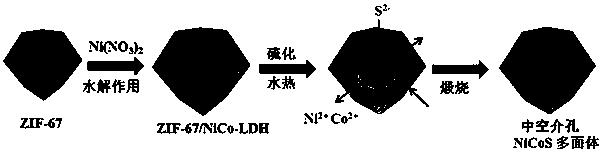

[0027] Specific embodiment 1: This embodiment describes a method for preparing a hollow mesoporous structure NiCoS polyhedron, such as figure 1 As shown, the method steps are as follows:

[0028] Step 1: Dissolve 3.495g divalent cobalt salt in 120mL methanol (AR, 99.5%), dissolve 3.942g 2-methylimidazole in 40mL methanol (AR, 99.5%), mix and stir the two solutions obtained , static, to get ZIF-67 (zeolite imidazolate skeleton-67);

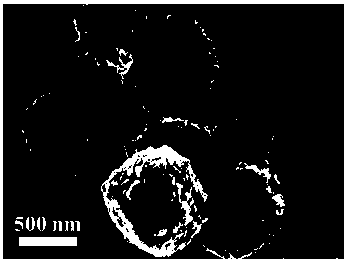

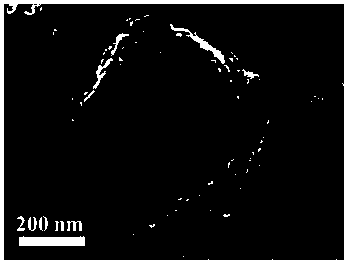

[0029] Step 2: Mix and stir ZIF-67 prepared in step 1 with nickel nitrate, centrifuge for 10 minutes at a speed of 10,000 r / min, and dry in vacuum for 12 hours to obtain the intermediate ZIF-67 / NiCo double-layer hydroxide (NiCo- LDH), such as figure 2 , image 3 shown;

[0030] Step 3: Disperse the intermediate ZIF-67 / NiCo double-layer hydroxide obtained in step 2 in 20 mL of ethanol solution, add 0.06 g of thioacetamide for stirring, and then place it in a reactor for hydrothermal reaction. The heating temperature is 120°C, the hydrothermal...

specific Embodiment approach 2

[0031] Specific embodiment two: a method for preparing a hollow mesoporous structure NiCoS polyhedron described in specific embodiment one, in step one, the divalent cobalt salt is Co(NO 3 ) 2 •6H 2 O. CoSO 4 •H 2 O, CoCl 2 •6H 2 O or Co(CH 3 COO) 2 • 4H 2 O.

specific Embodiment approach 3

[0032] Embodiment 3: The method for preparing a hollow mesoporous NiCoS polyhedron described in Embodiment 1, in step 1, the molar mass ratio of the divalent cobalt salt to 2-methylimidazole is 1:4.

[0033] Embodiment 4: In the method for preparing a hollow mesoporous NiCoS polyhedron described in Embodiment 1, in step 1, the resting time should be 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com