Fully-automatic glass breaking-off device

A fully automatic, glass technology, used in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem that the control accuracy and debugging difficulty cannot reach the predetermined effect, the function of glass breaking equipment is not very perfect, affecting the glass Problems such as normal operation of production line equipment, to achieve the effect of fast and convenient adjustment of output speed, ingenious structure design, and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

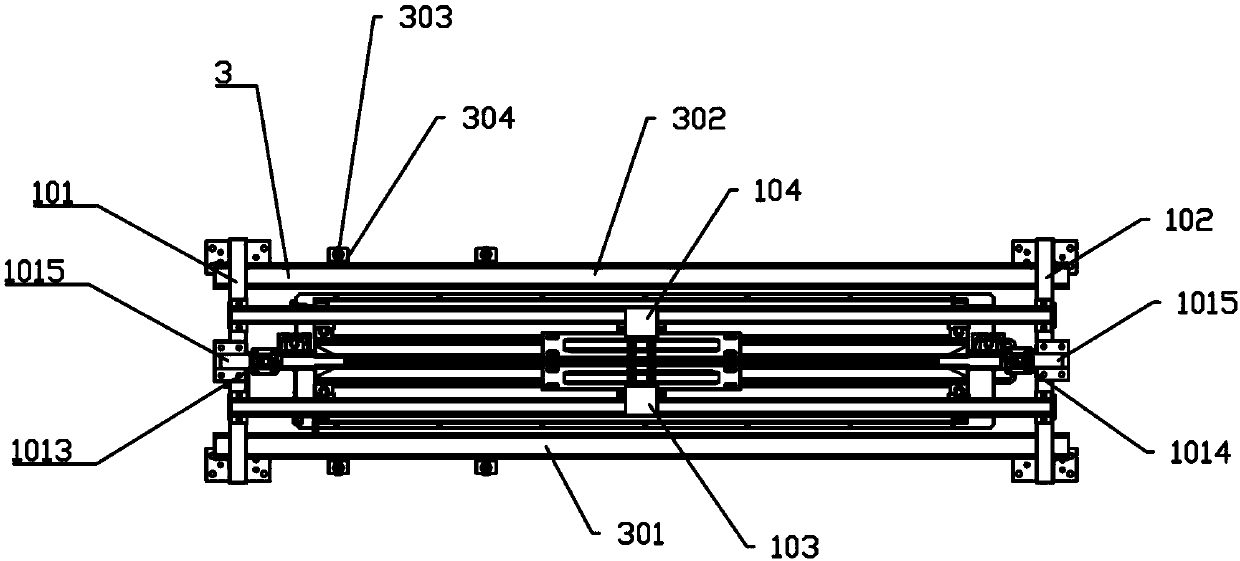

[0079] according to Figure 1 to Figure 5 As shown, a fully automatic glass breaking device mainly includes a breaking mechanism 1 , a chip guiding mechanism 2 , a glass supporting mechanism 3 and a limit sensing mechanism 4 .

[0080] according to image 3 As shown, the breaking mechanism 1 includes a left fixed frame 101, a right fixed frame 102, a first slide rail fixed mount 103, a second slide rail fixed mount 104, a first edge breaking cylinder 105, a second edge breaking cylinder 106, The first blade fixing frame 107, the second blade fixing frame 108, the first edge breaking blade 109, the second edge breaking blade 1010, the third slide rail fixing frame 1011, the third blade fixing frame 1012, the third breaking piece cylinder 1013, The fourth breaking cylinder 1014, the fixing seat 1015 of the breaking cylinder, and the third breaking blade 1016; the left fixed frame 101 and the right fixed frame 102 are the load-bearing skeletons of the whole device, which are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com