Technological system and technological method for performing cryogenic quick freezing on seafoods by air

A process system and air technology, which is applied in the direction of freezing/cooling preservation of meat/fish, food processing, climate change adaptation, etc., can solve the problems of large nitrogen evaporation loss, cooling capacity loss, and high processing cost, so as to reduce investment and production cost, production cost reduction, and effect of liquefaction cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

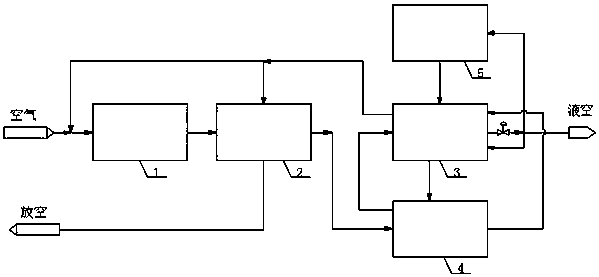

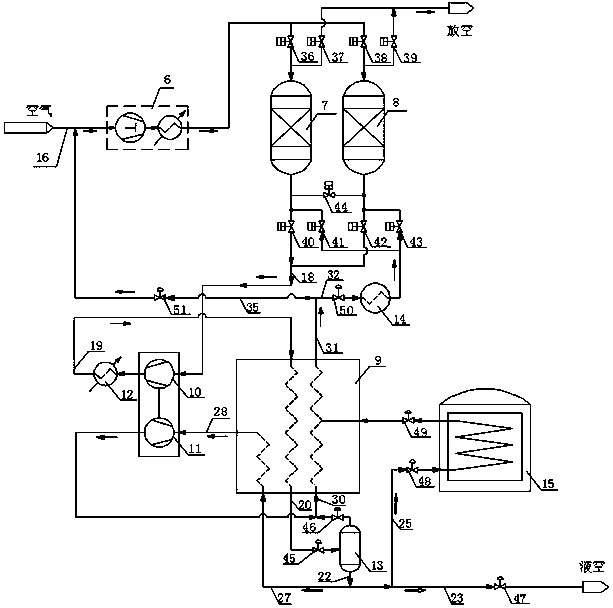

[0033]Below in conjunction with accompanying drawing and by embodiment the present invention will be described in further detail, single arrow in the figure represents the trend of gas air, and hollow arrow represents the trend of liquid air, and the following examples are explanations of the present invention and the present invention is not limited to the following Example.

[0034] Example.

[0035] see Figure 1 to Figure 2 , a process system for deep freezing and quick freezing of seafood using air, comprising an air compressor 6, an adsorption system, first to ninth switching valves, first to seventh throttle valves, a turbo expander, a cooler 12, a low temperature Heat exchanger 9, gas-liquid separator 13, storage tank, seafood cryogenic quick-freezing box 15, heater 14.

[0036] The turboexpander is divided into a turboexpander booster end 10 and a turboexpander expansion end 11. The adsorption system consists of a first adsorption tower 7 and a second adsorption tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com