Control device for internal combustion engine

A control device and internal combustion engine technology, applied in engine control, fuel injection control, electrical control, etc., can solve problems such as air-fuel ratio deviation, achieve high-precision inference, and prevent the reduction of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Next, a first embodiment of the present invention will be described with reference to the drawings.

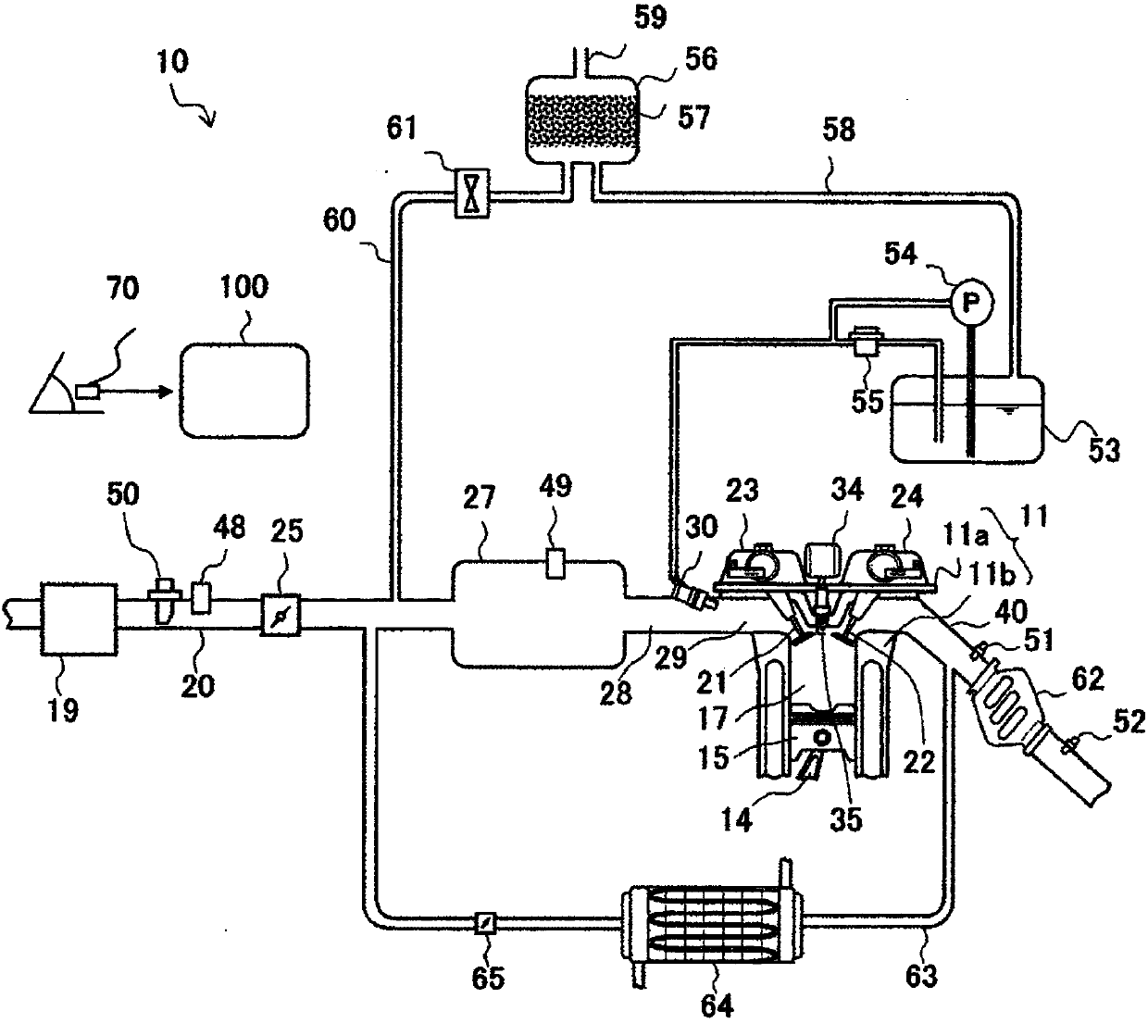

[0040] figure 1 It is an overall configuration diagram of an internal combustion engine equipped with a control device for an internal combustion engine according to the present invention.

[0041] The internal combustion engine 10 is, for example, a spark ignition multi-cylinder internal combustion engine equipped with four cylinders, and includes a cylinder 11 composed of a cylinder head 11a and a cylinder block 11b, and a piston 15 slidably inserted into each cylinder of the cylinder 11. The piston 15 passes through The connecting rod 14 is connected to a crankshaft (not shown). Also, above the piston 15 is formed a combustion chamber 17 having a top plate portion of a predetermined shape, and inside the combustion chamber 17 of each cylinder, a spark plug 35 to which a high-voltage ignition signal is supplied from an ignition coil 34 is placed downward.

[0042] I...

Embodiment 2

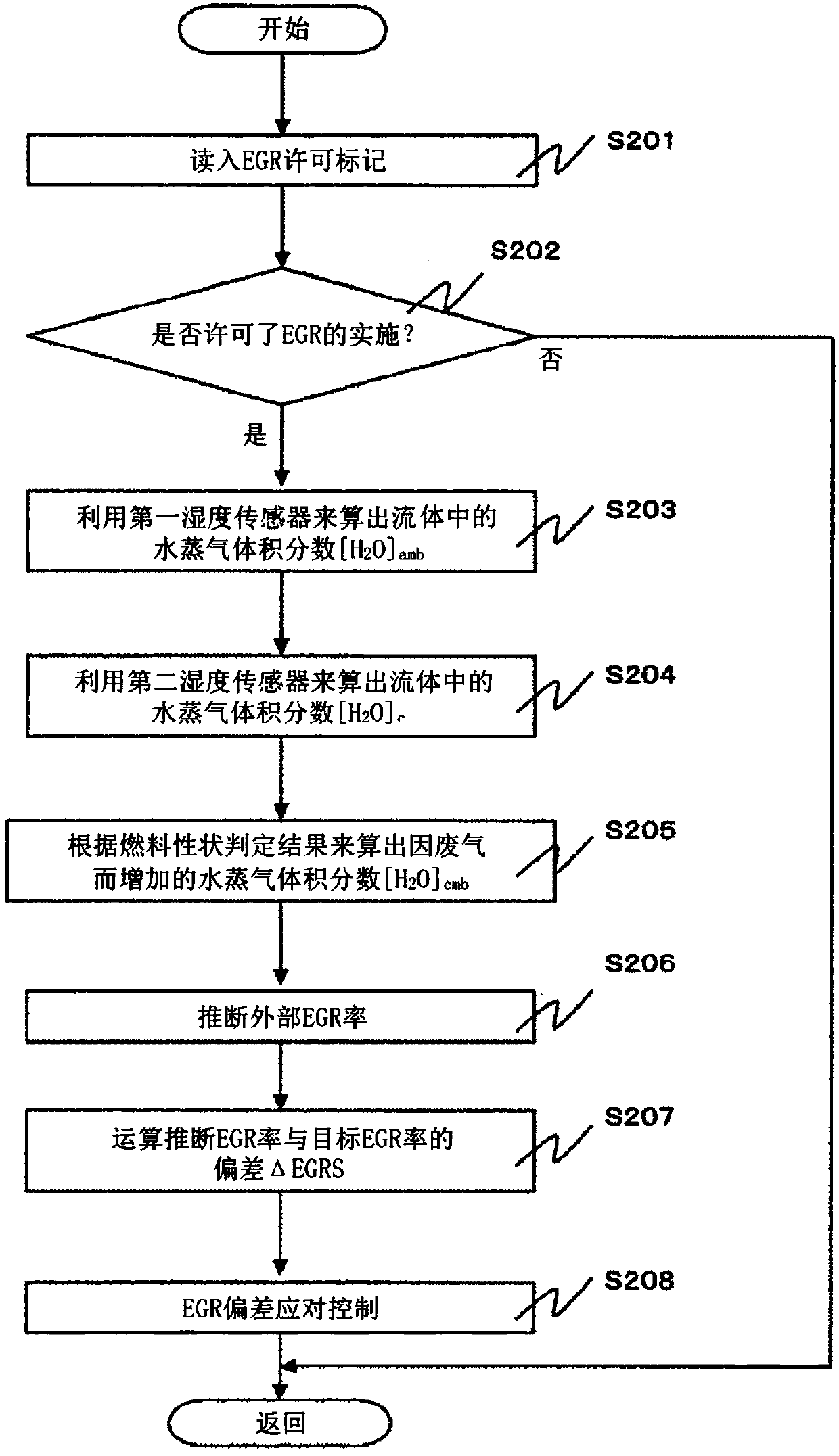

[0135] Next, a second embodiment will be described below with reference to the drawings. The overall composition of the internal combustion engine has removed the EGR systems such as the EGR pipeline 63, the EGR cooler 64, and the EGR valve 65. figure 1 same.

[0136] Figure 10 In order to use the relative humidity of the first humidity sensor 48 and the second humidity sensor 49 respectively provided upstream and downstream of the connecting portion of the intake pipe 20 and the purge introduction pipe 60 to estimate the fresh air and blown air at the downstream of the connecting portion. Flowchart for controlling the fuel injection amount based on the purge air-fuel ratio, which is the ratio of the purge gas, and the estimated purge air-fuel ratio.

[0137] In S1001, the relative humidity RH is read from the first humidity sensor 48 amb , temperature T amb , pressure P amb , move to the next step.

[0138] In S1002, the relative humidity RH is read from the second hum...

Embodiment 3

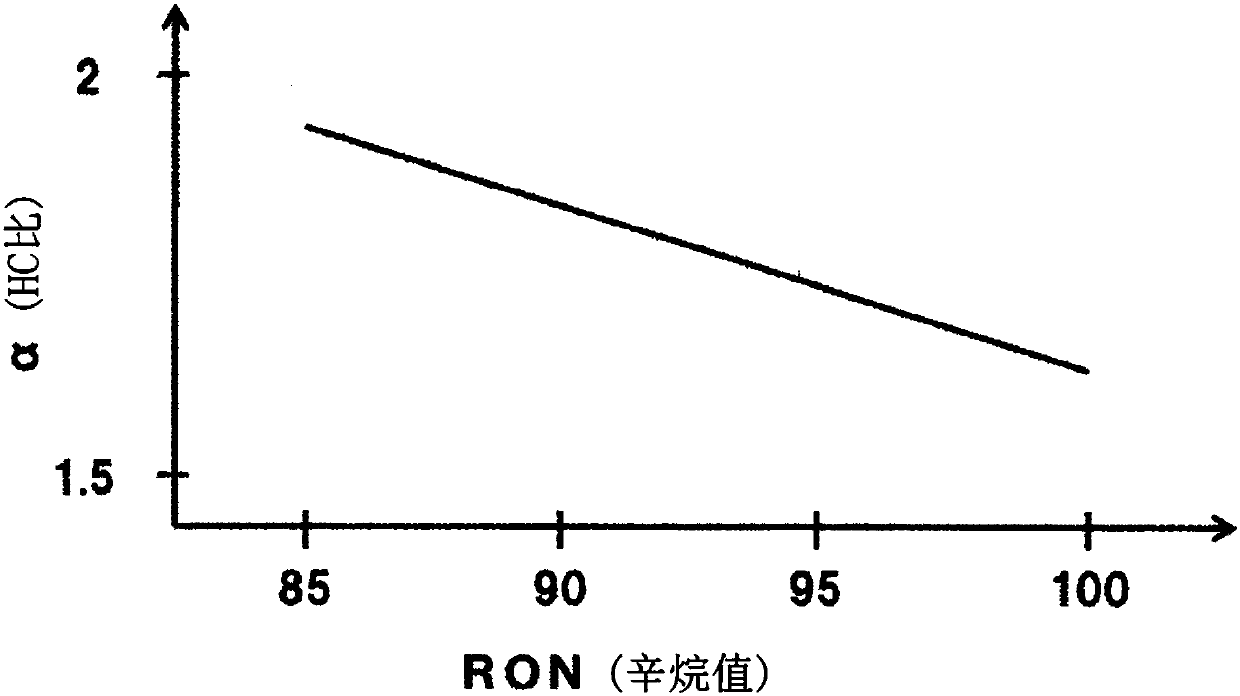

[0173] Next, a third embodiment will be described below with reference to the drawings. The overall composition of the internal combustion engine has removed the EGR systems such as the EGR pipeline 63, the EGR cooler 64, and the EGR valve 65. figure 1 same.

[0174] Figure 12 In order to use the absolute humidity of the first humidity sensor 48 and the second humidity sensor 49 respectively provided upstream and downstream of the connection part of the intake pipe 20 and the purge introduction pipe 60 to estimate the fresh air and blown air at the downstream of the connection part. Flowchart for controlling the fuel injection amount based on the purge air-fuel ratio, which is the ratio of the purge gas, and the estimated purge air-fuel ratio.

[0175] In S1201, read the air volume signal Q detected by the air flow sensor 50 a, move to the next step. Air quantity signal Q a The unit is [g / s].

[0176] In S1202, read the purge flow signal Q b , move to the next step. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com