Li5feo4 prelithiation agent and preparation method of lithium ion capacitor and lithium ion capacitor

A capacitor and lithium ion technology, applied in the field of capacitors, lithium ion capacitors and the preparation of pre-lithiation agents, can solve problems such as affecting Li, and achieve the effects of controllable pre-lithiation degree, improved cycle stability, and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

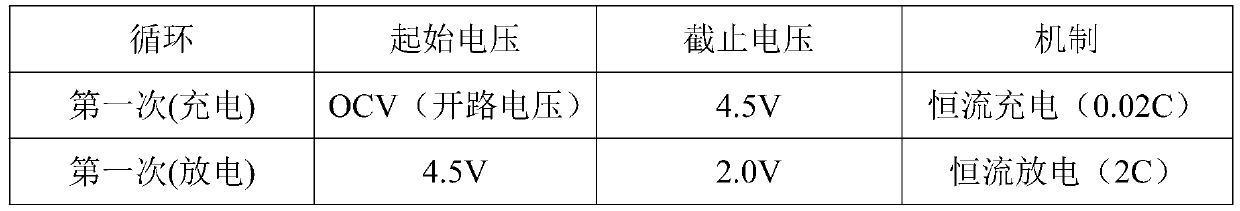

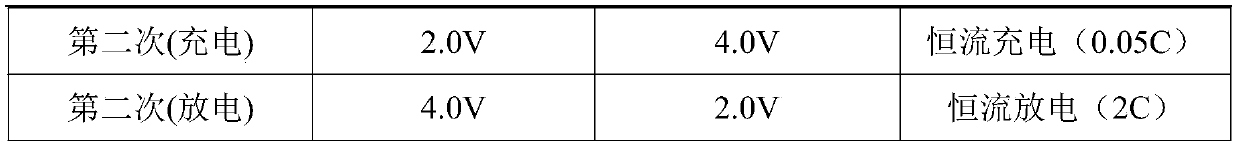

[0028] One using Li 5 FeO 4 The preparation method of the lithium ion capacitor of pre-lithiation, comprises the following steps:

[0029] 1. Li 5FeO 4 Preparation of:

[0030] (1) Nano Fe 2 o 3 Prepared by solution heat method: Dissolve ferric nitrate and polyvinylpyrrolidone in dimethylformamide at a mass ratio of 1:1, stir evenly, move the solution to a high-pressure reactor, react at 130°C for 8 hours, and then The product is taken out and centrifuged, washed, suction filtered and dried to obtain nano-Fe with a particle size of 280nm 2 o 3 ;

[0031] (2) Weigh LiOH-H at a molar ratio of 10:1 2 O and nano Fe 2 o 3 , after ball milling for 6 hours, react at 650°C for 12 hours under the condition of argon, and obtain a diameter of 9 μm after cooling, and a capacity of 490mAh·g -1 , the first effect is 13%, and the specific surface area is 240m 2 g -1 Li 5 FeO 4 .

[0032] 2. Activated carbon (50wt%), Li 5 FeO 4 The pre-lithiation agent (30wt%), Super P (10w...

Embodiment 2

[0039] One using Li 5 FeO 4 The preparation method of the lithium ion capacitor of pre-lithiation, comprises the following steps:

[0040] 1. Li 5 FeO 4 Preparation of:

[0041] (1) Nano Fe 2 o 3 Prepared by solution heat method: Dissolve ferric nitrate and polyvinylpyrrolidone in dimethylformamide at a mass ratio of 2:1, stir evenly, move the solution to a high-pressure reactor, react at 150°C for 24 hours, and then The product is taken out and centrifuged, washed, suction filtered and dried to obtain nano-Fe with a particle size of 280nm 2 o 3 ;

[0042] (2) Weigh LiOH-H at a molar ratio of 10:1 2 O and nano Fe 2 o 3 , after ball milling for 10 hours, react at 750°C for 24 hours under argon gas, and obtain a diameter of 7 μm and a capacity of 550mAh g after cooling. -1 , the first effect is 8%, and the specific surface area is 480m 2 g -1 Li 5 FeO 4 .

[0043] 2. Activated carbon (70wt%), Li 5 FeO 4 The pre-lithiation agent (10wt%), Super P (10wt%) and PVD...

Embodiment 3

[0051] One using Li 5 FeO 4 The preparation method of the lithium ion capacitor of pre-lithiation, comprises the following steps:

[0052] 1. Li 5 FeO 4 Preparation of:

[0053] (1) Nano Fe 2 o 3 Prepared by solution heat method: Dissolve ferric nitrate and polyvinylpyrrolidone in triethylene glycol at a mass ratio of 3:1, stir evenly, move the solution to a high-pressure reactor, react at 180°C for 30 hours, and then dissolve the product Take out and centrifuge, wash, filter, and dry to obtain nano-Fe with a particle size of 210nm 2 o 3 ;

[0054] (2) Weigh LiOH-H at a molar ratio of 10:1 2 O and nano Fe 2 o 3 , after ball milling for 10 hours, react at 700°C for 48 hours under the condition of argon, and obtain a diameter of 6 μm and a capacity of 640mAh·g after cooling. -1 , the first effect is 7%, and the specific surface area is 730m 2 g -1 Li 5 FeO 4 .

[0055] 2. Activated carbon (60wt%), Li 5 FeO 4 The pre-lithiation agent (25wt%), Super P (10wt%) an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com