Submarine cable pressure monitoring system

A pressure monitoring and submarine cable technology, which is applied in the field of monitoring systems, can solve the problems of unable to eliminate the fault section, and cannot monitor the pressure, leakage, and damage of submarine cables in real time, so as to achieve the effect of protection against breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

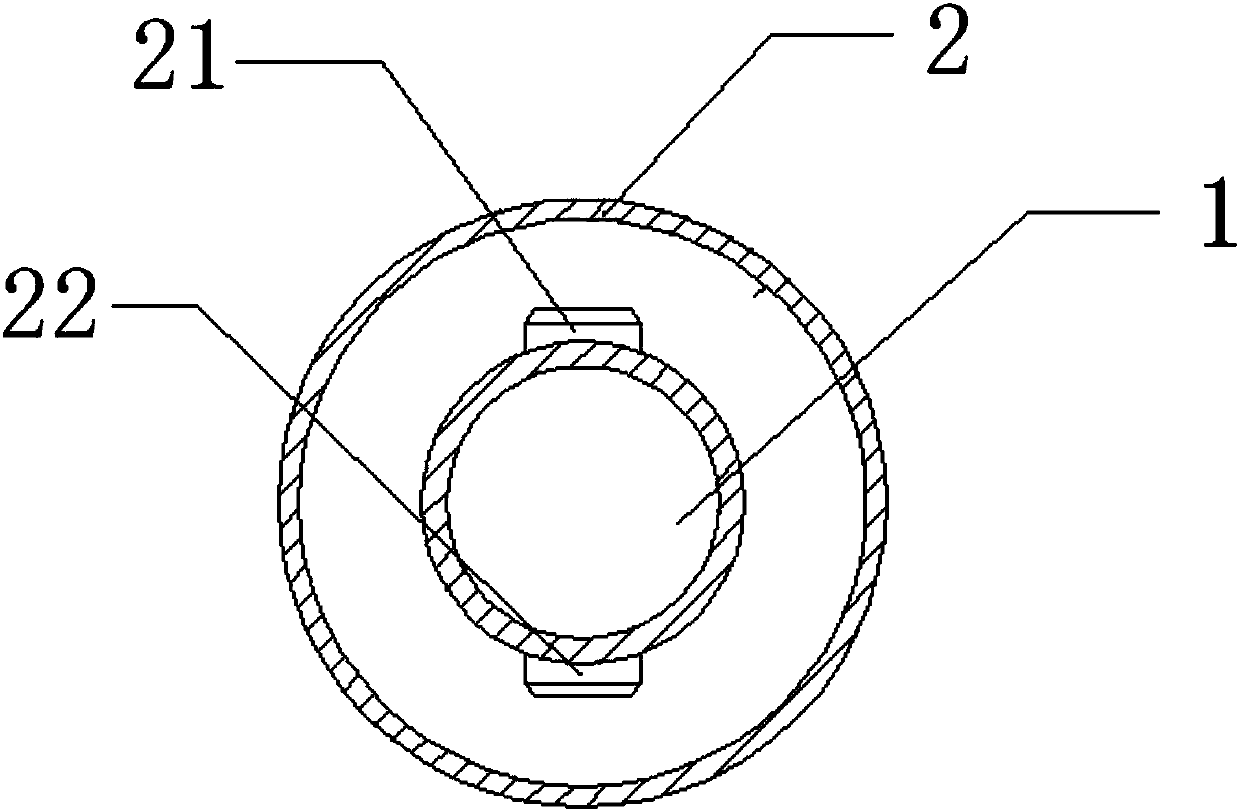

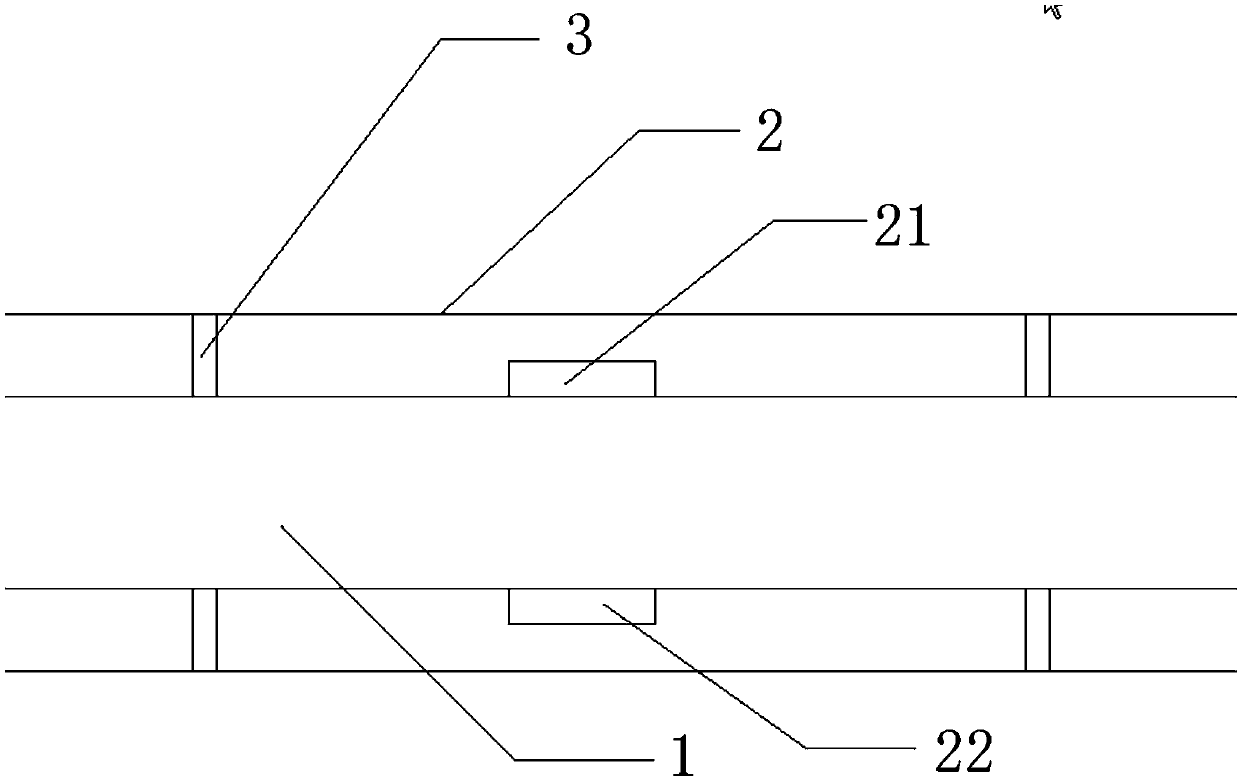

[0021] Such as figure 1 , 2 As shown, a submarine cable pressure monitoring system of the present invention includes a protective layer 2 arranged on the outside of the cable body 1, there is a gap between the cable body 1 and the protective layer 2, and the protective layer 2 passes through the isolation plate 3 every 1 km For protective partitioning, one end of the isolation plate 3 is connected to the inner wall of the protective layer 2, and the other end is connected to the outer wall of the cable body 1. Each partitioned protective layer 2 is provided with different alarm modules 21 and detection modules 22, and the control center receives the alarm. The signals sent by the module 21 and the detection module 22 are used to monitor the operation of the cable. The various detection modules and alarm modules installed in the gap between the cable body and the protective layer can detect the cable condition in time, and send the detected data to the control center in real t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com