Waste heat recovery method for improving stability of unstable waste heat resource in sintering process

A sintering process, stable technology, applied in the field of stable waste heat recovery, can solve the problems of reducing the effect of waste heat recovery, reducing the operation rate of waste heat recovery system, etc., to achieve the effect of reducing the return rate, increasing waste heat recovery energy, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

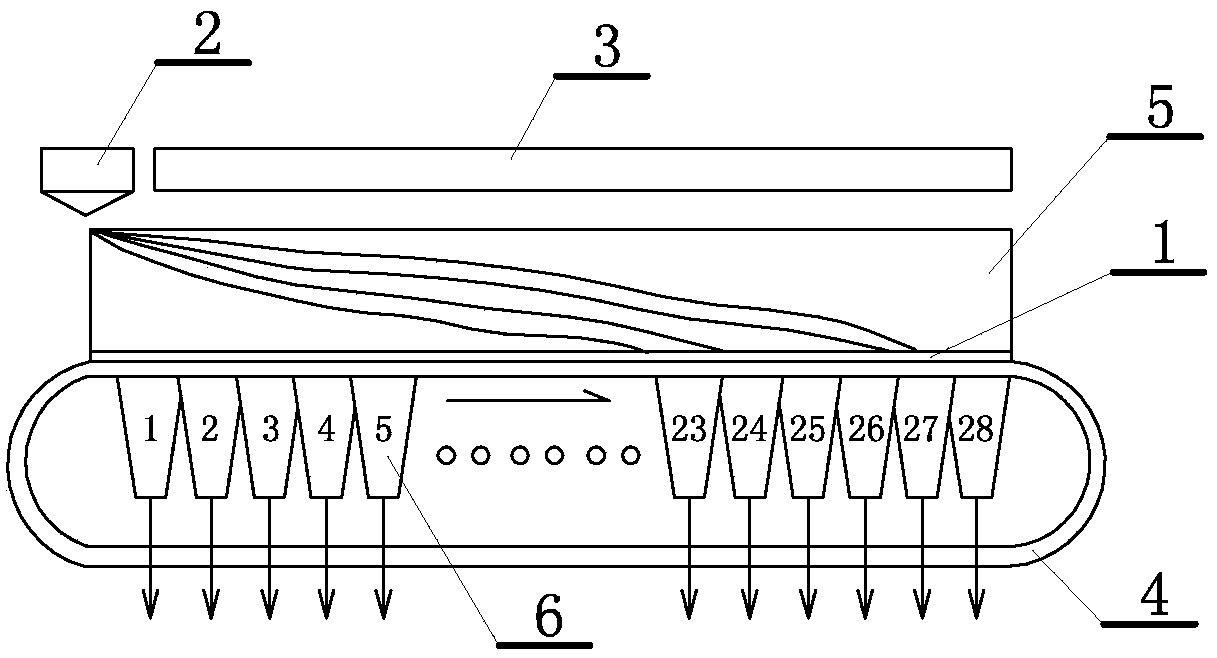

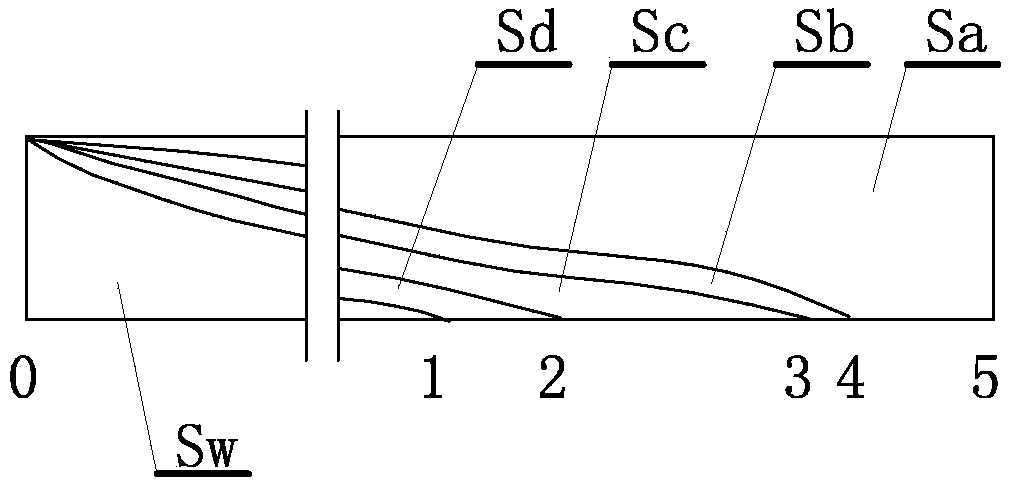

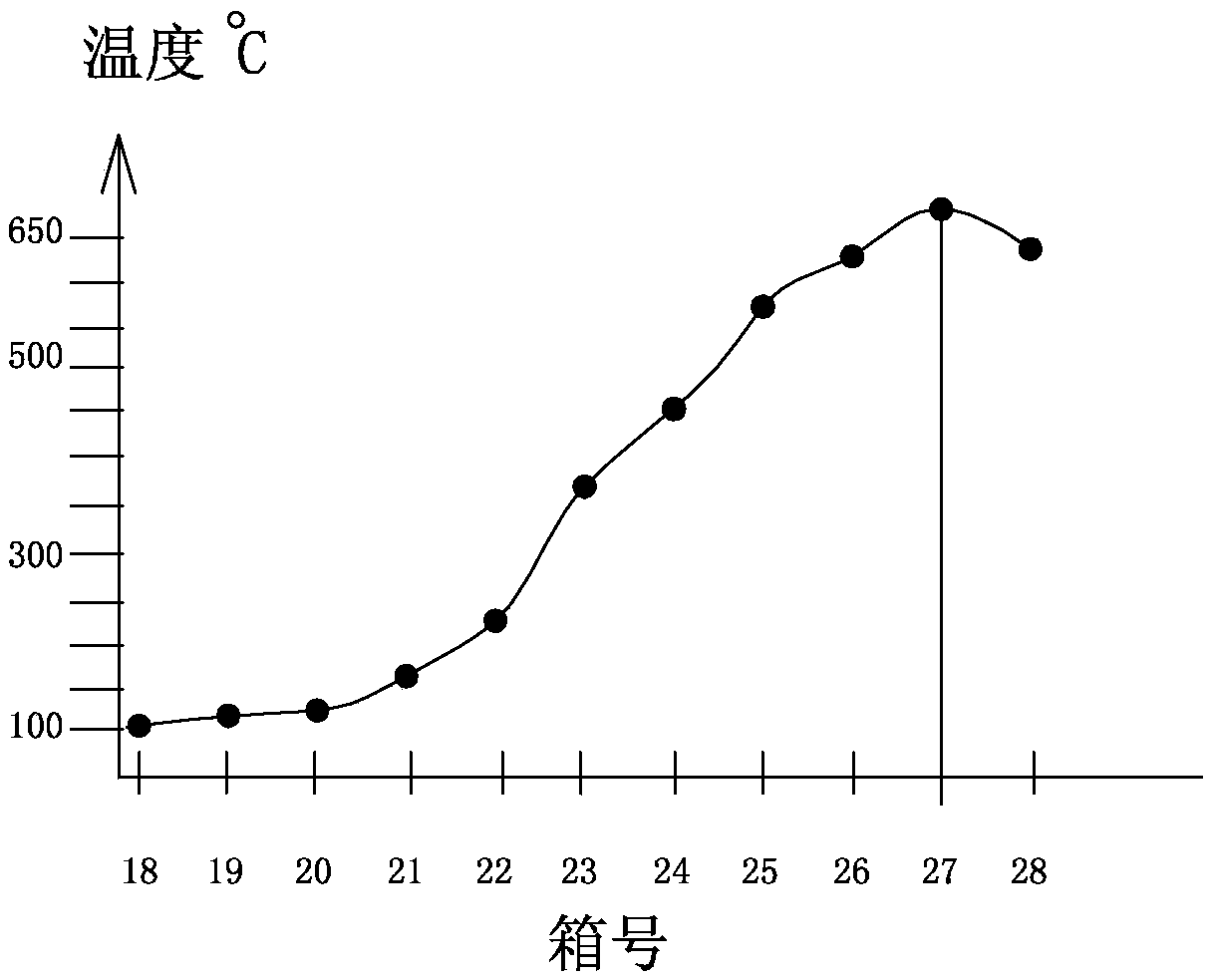

[0025] A stable waste heat recovery method to improve unstable waste heat resources in the sintering process, such as figure 1 Shown is a sinter bed section 1 including a sintering furnace. An igniter 2 is provided at the beginning of the sinter bed section, and a plurality of combustion aid injection nozzles 3 are arranged longitudinally and sequentially on the upper end side of the sinter bed section after the igniter to spray to the ignited raw material ore. Combustion aid (coal gas), the grate conveyor belt 4 transports the raw material ore 5 with a certain thickness equipped with carbon particles to sinter the raw material ore after passing through the sintering bed section, and the lower end side of the sintering bed section is arranged in sequence along the longitudinal sequence with a plurality of exhaust boxes 6, Exhaust hot air extracted from multiple exhaust boxes is used as waste heat for the generator to generate electricity. Each exhaust box is equipped with an ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com