Hydraulic system and control method capable of providing suitable performance for load

A technology of hydraulic system and control method, which is applied in the field of hydraulic system to achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

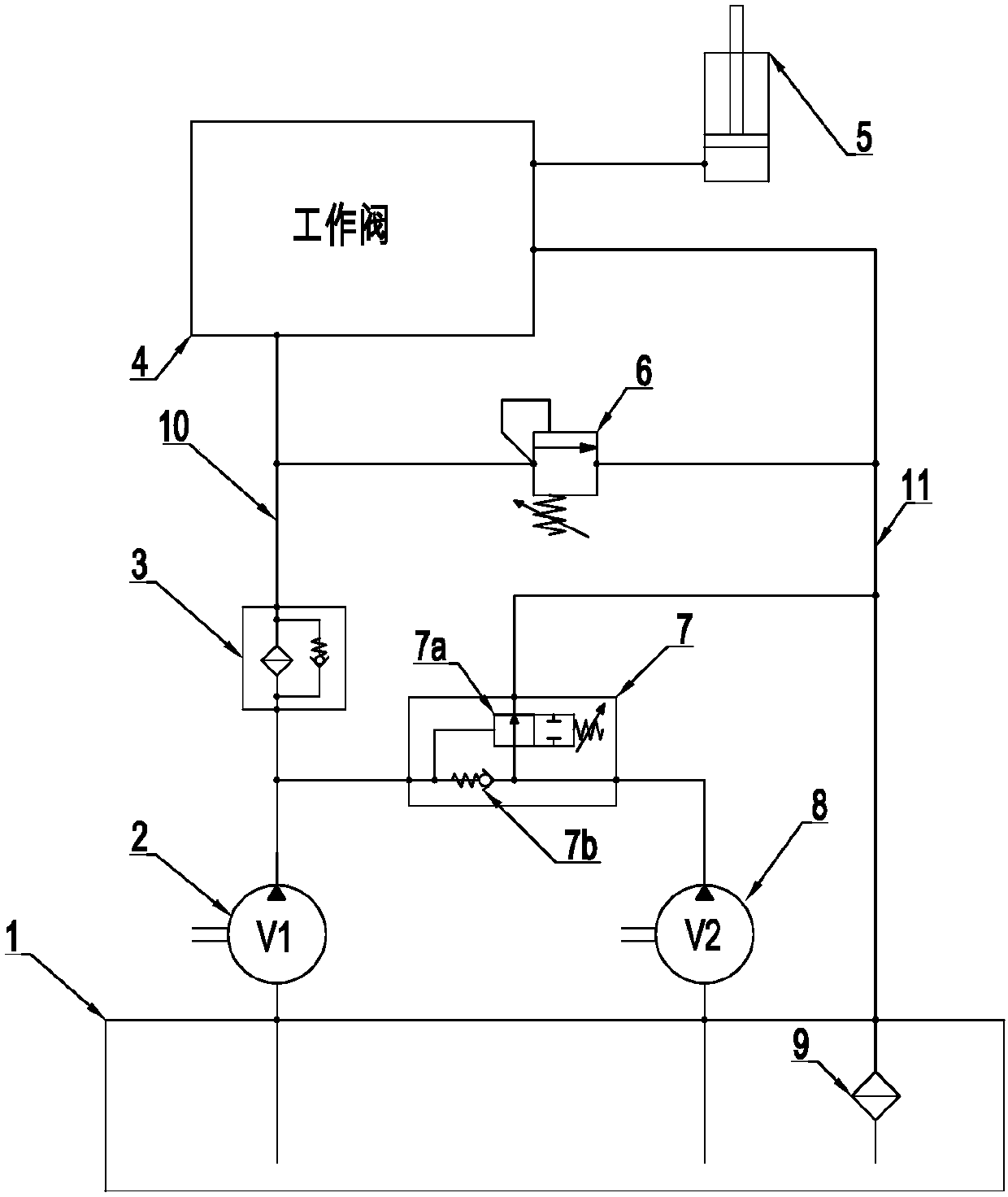

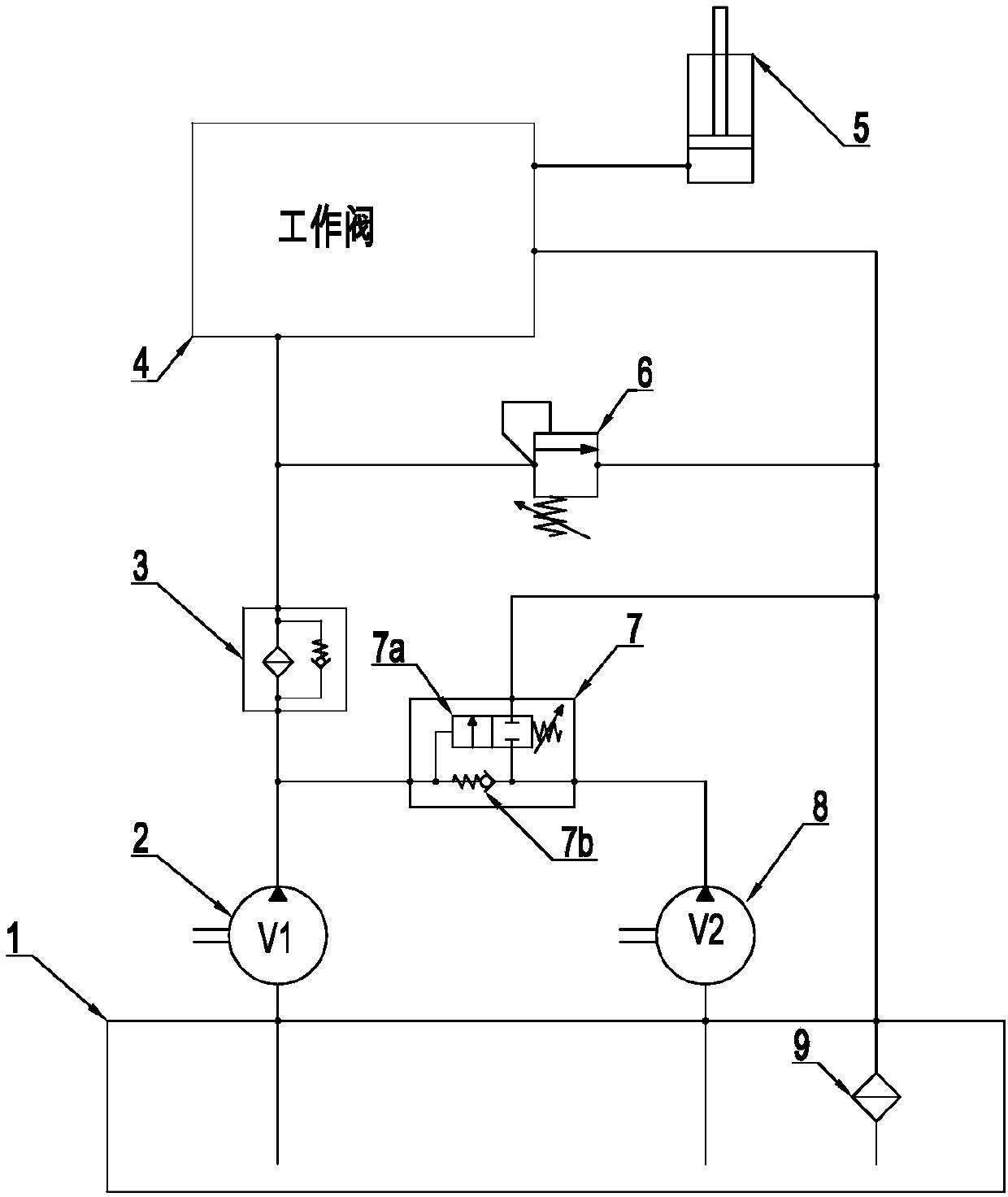

[0023] Examples, see figure 1 , figure 2 As shown, a hydraulic system of the present invention that can provide suitable performance for loads includes a working valve 4 of industrial machinery or engineering machinery, and the working valve 4 is connected with an actuator for controlling cargo lifting. In this embodiment, the industrial machinery or construction machinery refers to a forklift, and the actuator is a lifting cylinder 5 .

[0024] The present invention also includes a first hydraulic pump 2, a second hydraulic pump 8 and a control valve. The first hydraulic pump 2 is used as the main oil supply pump for the working valve 4. Once the working valve 4 has a flow demand, it will provide the oil for the working valve 4. Pressure oil: the second hydraulic pump 8 is configured to provide pressure oil to the working valve 4 when the working oil pressure of the working valve 4 is lower than a set value. The control valve is used to control whether the second hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com