Production method of natural-color anti-rusting body paper

A production method and original technology, applied in papermaking, papermaking, textile and papermaking, etc., can solve the problems of low yield, low water absorption, and more dust of color and rust base paper, and achieve stable moisture, high water absorption, and less dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

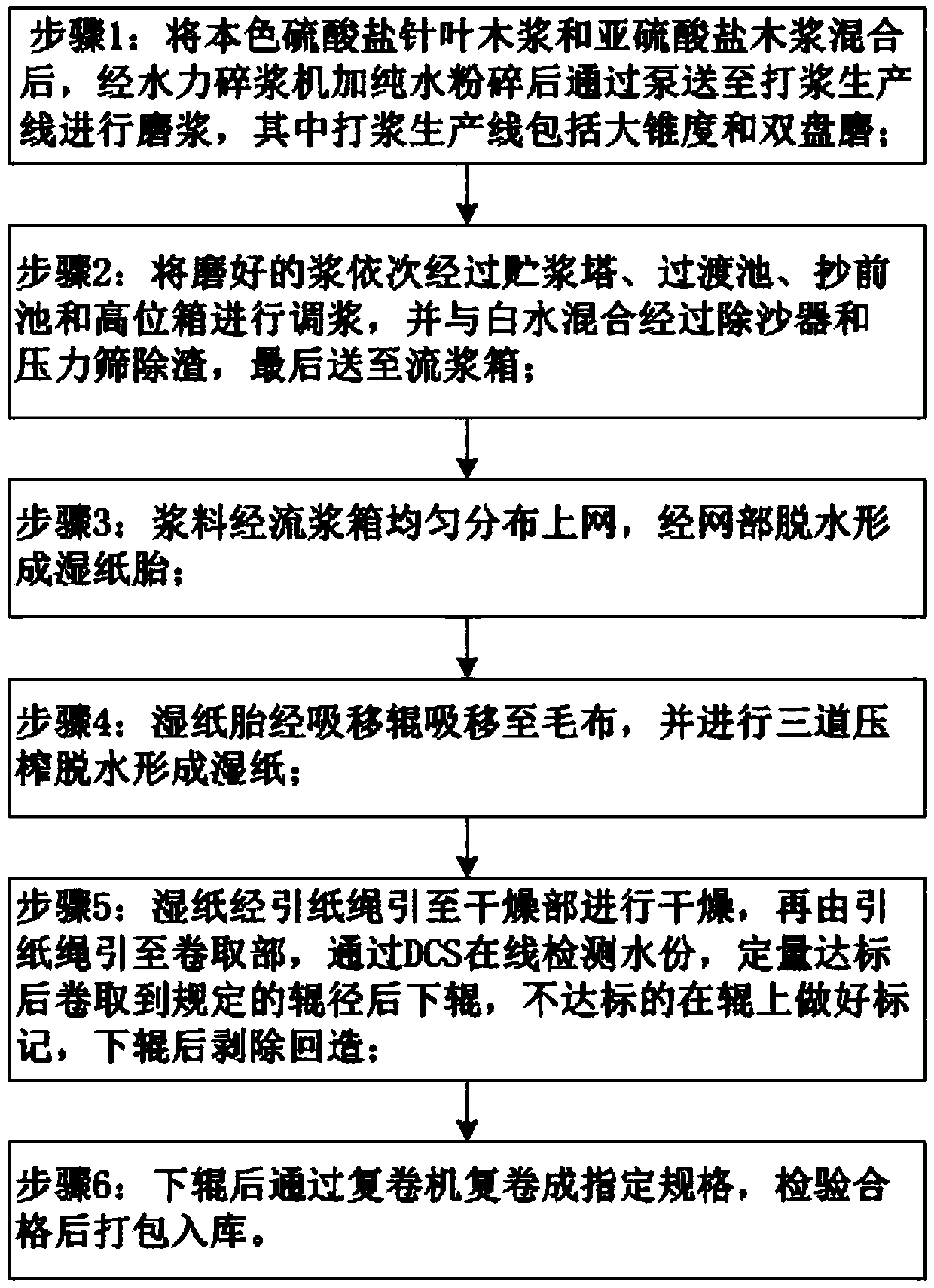

[0043] Step 1: After mixing natural sulphate softwood pulp and sulphite wood pulp at a mass percentage of 80% and 20% respectively, they are pulverized by a hydropulper and pure water, and then pumped to a beating production line for refining. The beating production line includes large taper and double disc mills; the beating degree is 35SR, the wet weight is 7.0g, and the conductivity of pure water is 18μs / cm.

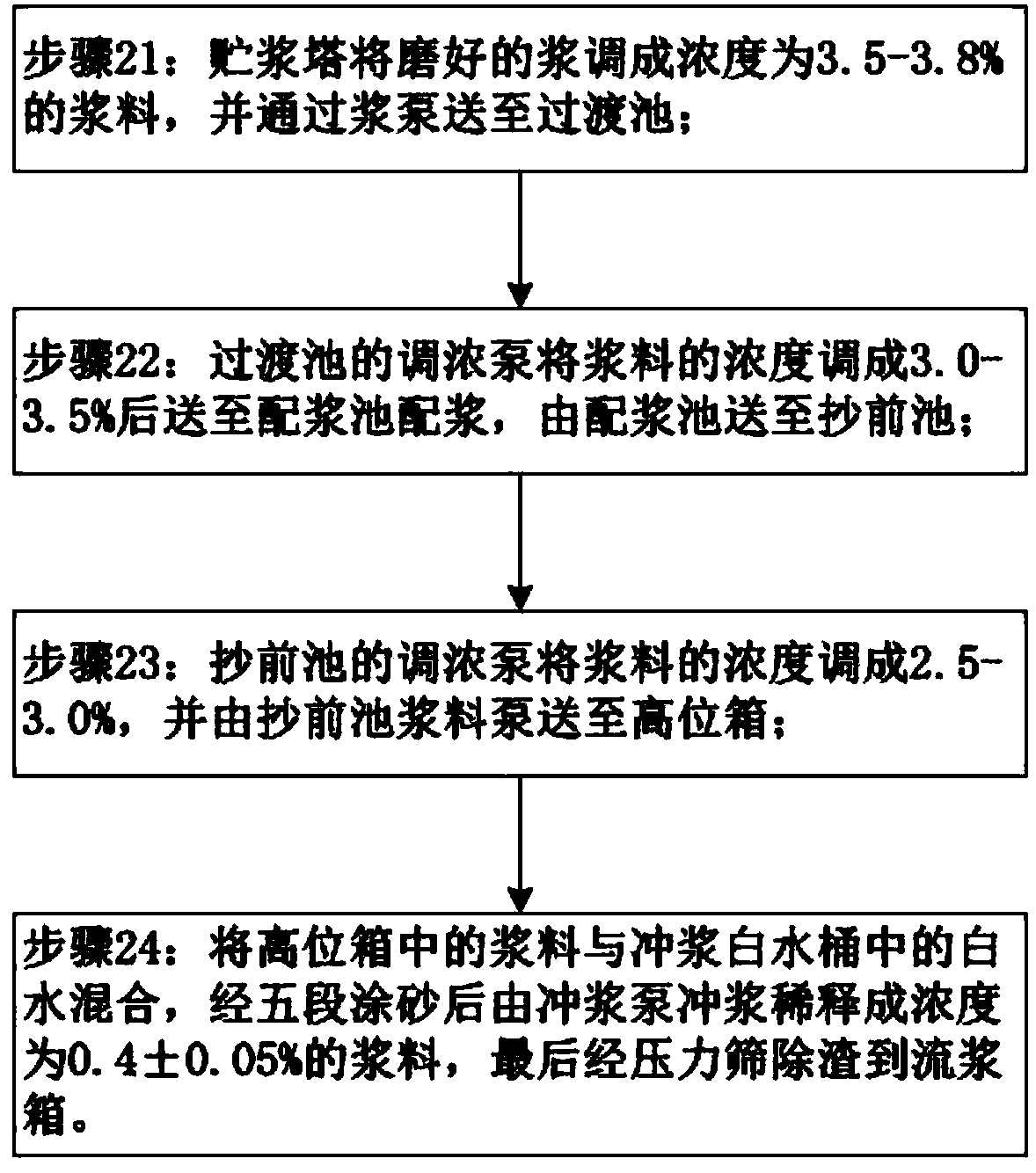

[0044] Step 2: Put the ground pulp through the pulp storage tower, the transition tank, the forebay and the high level box in turn to adjust the pulp, mix it with white water, pass through the sand remover and pressure screen to remove the slag, and finally send it to the headbox; the specific steps as follows:

[0045] Step 21: The slurry storage tower adjusts the ground pulp into a slurry with a concentration of 3.5%, and sends it to the transition tank through the slurry pump;

[0046] Step 22: The concentration pump in the transition tank adjusts the concentratio...

Embodiment 2

[0054]Step 1: After mixing natural sulphate softwood pulp and sulphite wood pulp at a mass percentage of 80% and 20% respectively, they are pulverized by a hydropulper and pure water, and then pumped to a beating production line for refining. The beating production line includes large taper and double disc mills; the beating degree is 36°SR, the wet weight is 8.0g, and the conductivity of pure water is 20μs / cm.

[0055] Step 2: Put the ground pulp through the pulp storage tower, the transition tank, the forebay and the high level box in turn to adjust the pulp, mix it with white water, pass through the sand remover and pressure screen to remove the slag, and finally send it to the headbox; the specific steps as follows:

[0056] Step 21: The slurry storage tower adjusts the ground pulp into a slurry with a concentration of 3.6%, and sends it to the transition tank through the slurry pump;

[0057] Step 22: The thickening pump in the transition tank adjusts the concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com