Water-based cleaning agent for high-speed railway maintenance

A high-speed railway, water-based technology, applied in the field of cleaning agent, can solve the problems of difficult cleaning, cleaning agent cannot be sprayed in place, and unsatisfactory cleaning effect, etc., and achieve the effect of low cost of use, high decontamination and cleaning ability, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described below in combination with specific embodiments.

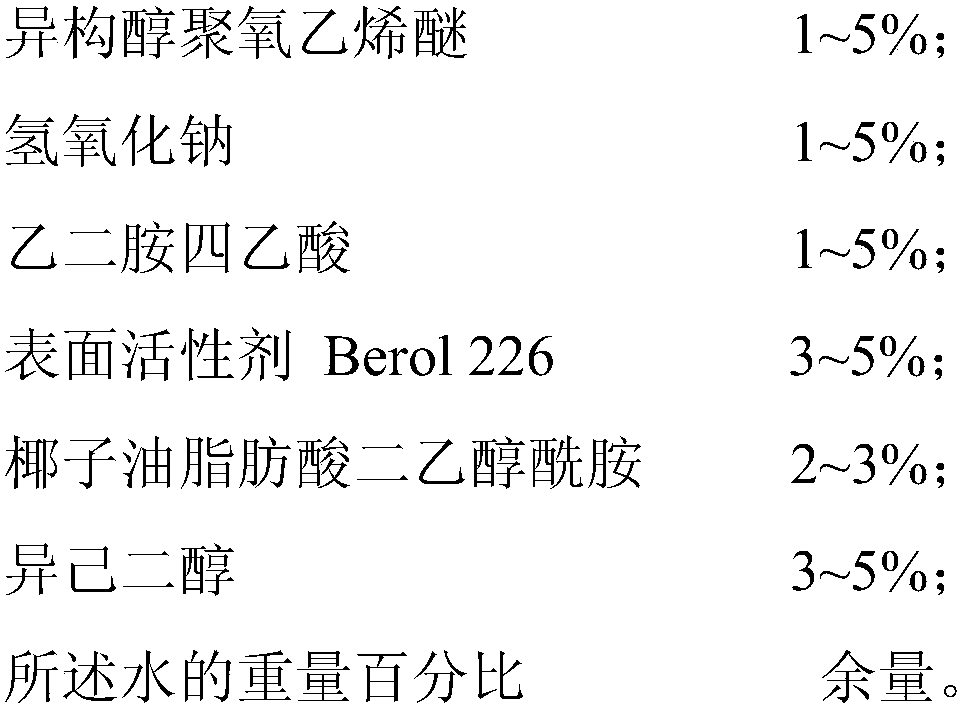

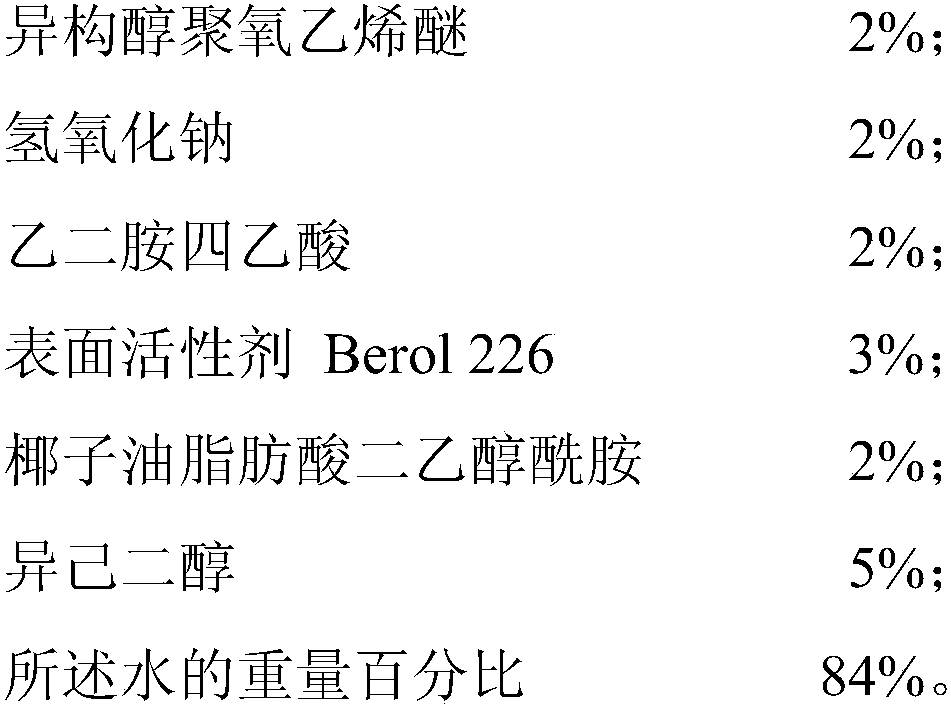

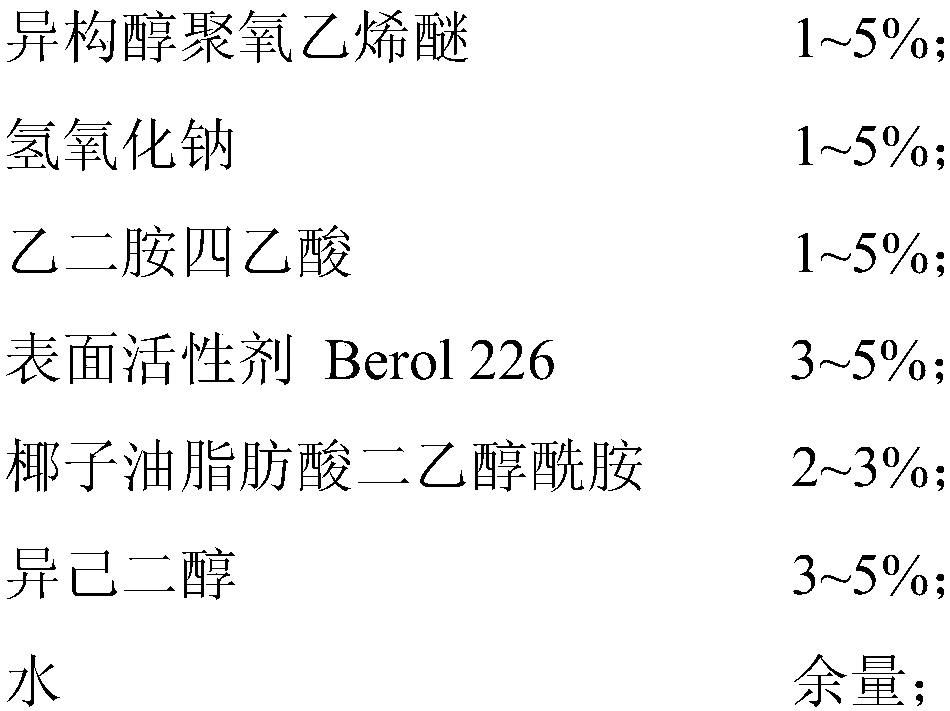

[0039] An aerosol tank of a water-based cleaning agent for maintenance of high-speed railways. The components of the water-based cleaning agent and their weight percentages are as follows:

[0040]

[0041]

[0042] The high-speed railway maintenance water-based cleaning agent aerosol tank of the specific embodiment is used to directly spray and clean the dirty surface. The cleaning is simple and fast, and most of the grease and soil can be cleaned. For complex parts, it can be cleaned directly without disassembly. At present, similar products are directly sprayed with a watering can to penetrate the dirty surface for 10 to 15 minutes, and then cleaned with a high-pressure water gun. It is not a big problem to clean the surface and the cleaning surface that is not particularly dirty. Gear oil leakage and grease overflow Some parts are difficult to clean, and parts with compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com