Modified asphalt, preparation and applications thereof

A technology of modified asphalt and asphalt, which is applied in the field of asphalt modifiers, can solve the problems of little spalling and looseness, and achieve excellent adhesion performance, high Brookfield viscosity and rebound rate, excellent high temperature performance and The effect of adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

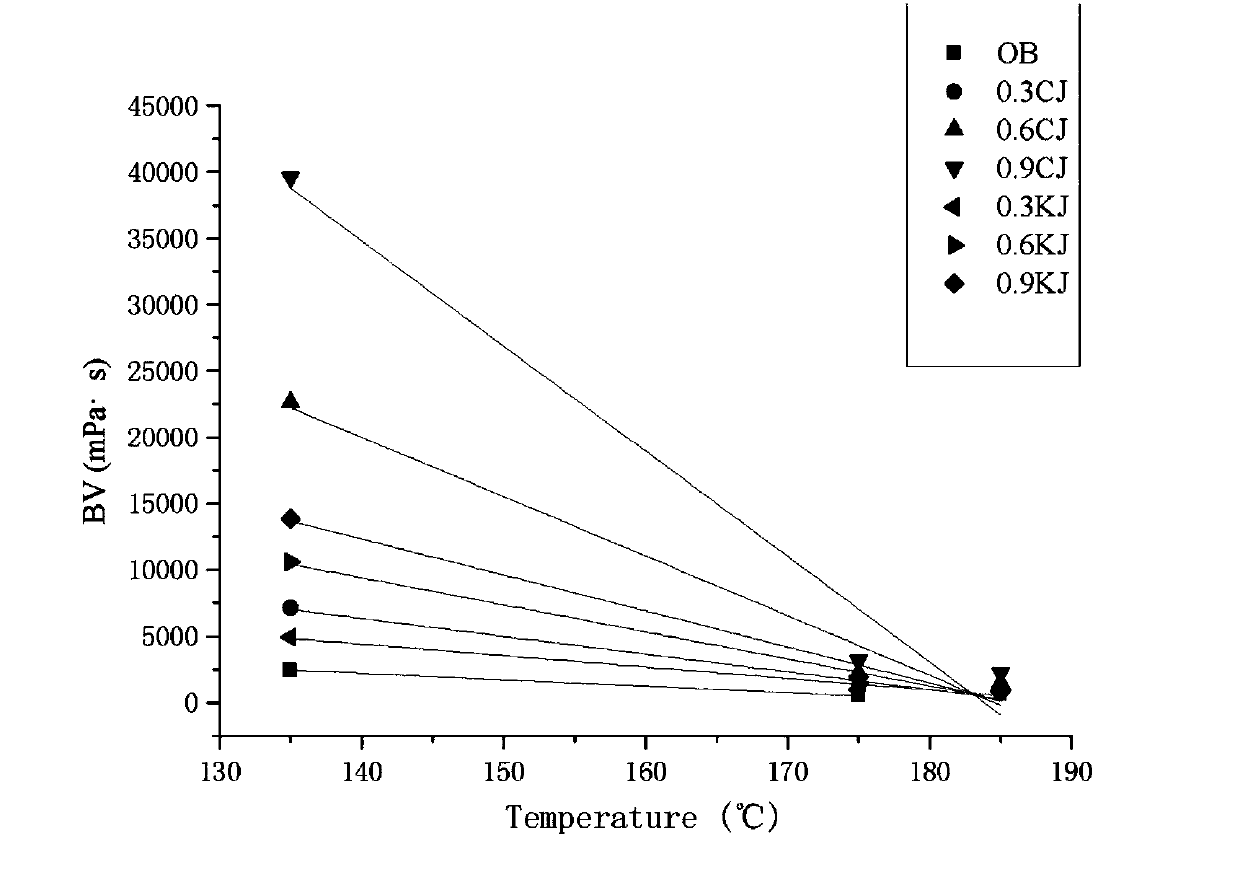

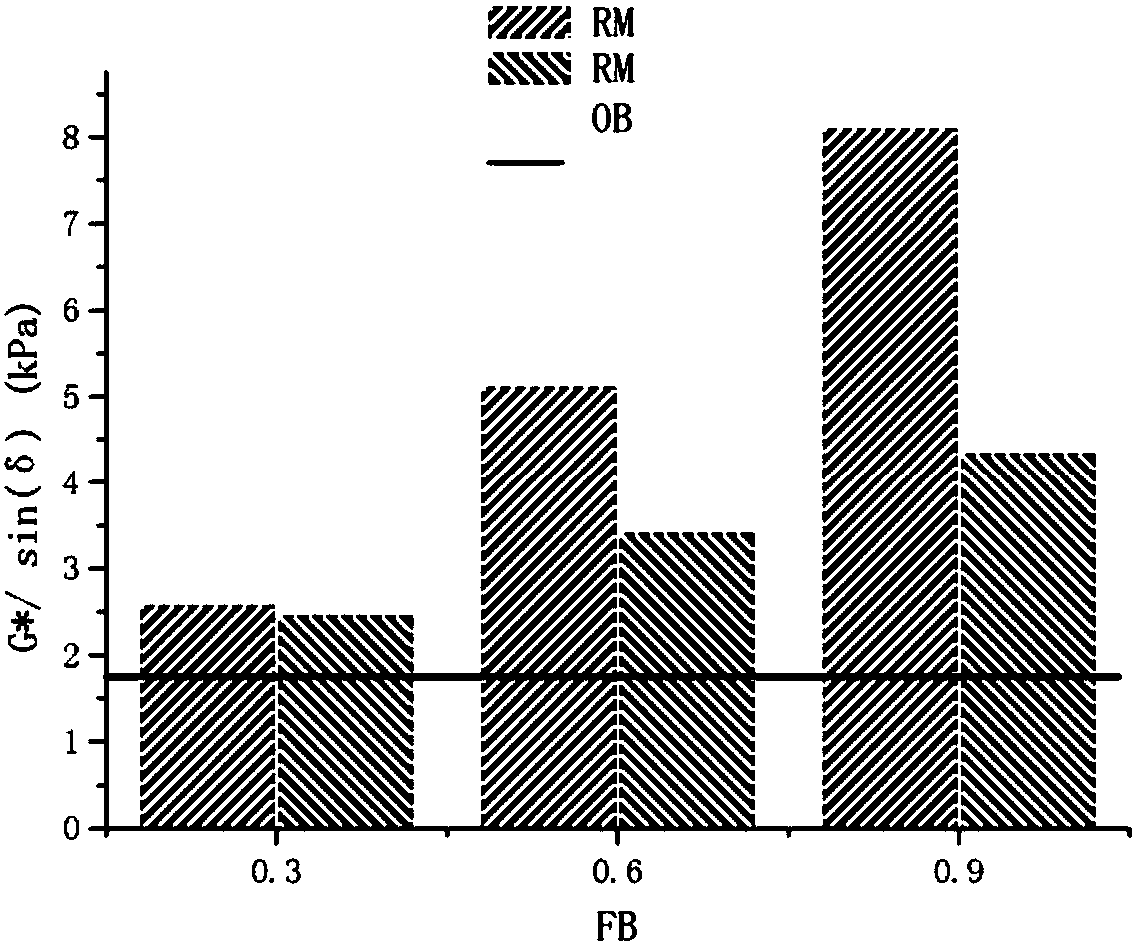

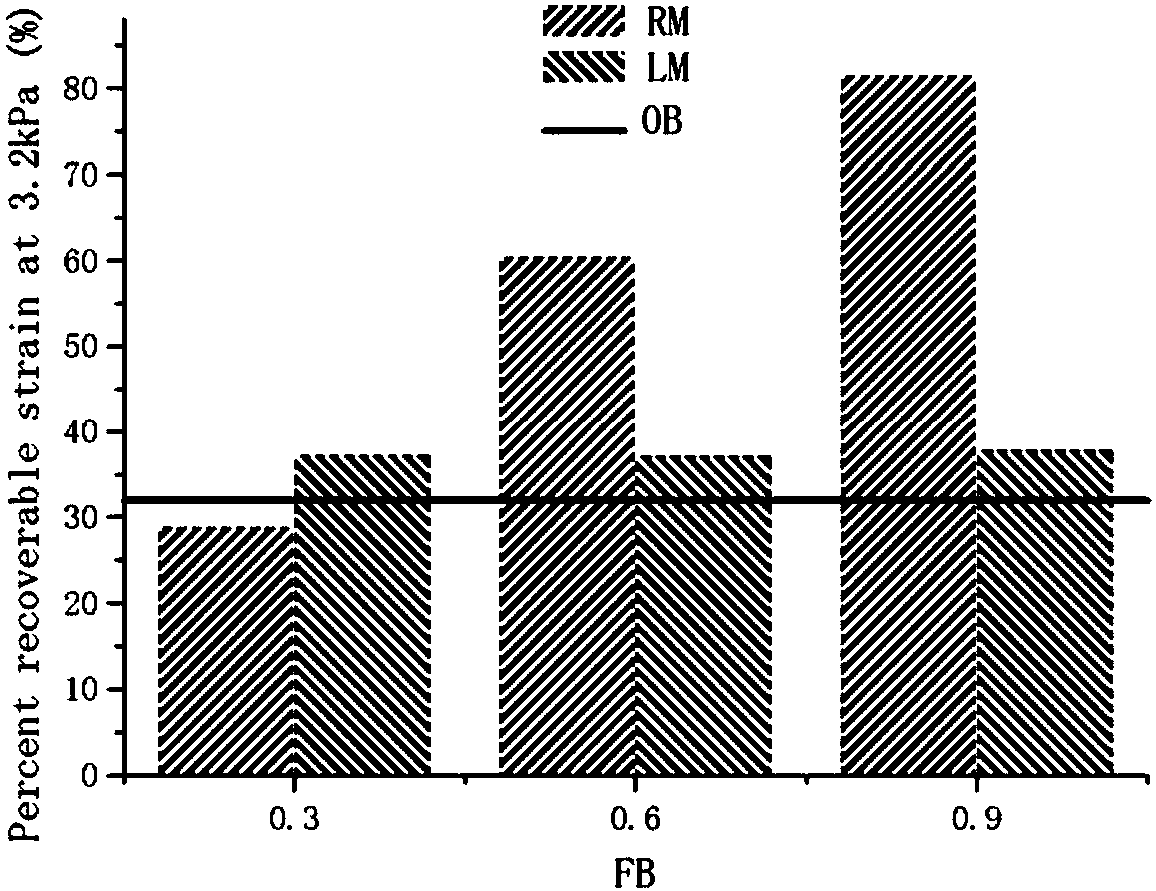

[0040] The modified asphalt mortar was prepared according to 1 mass part of domestic high-viscosity asphalt and 0.3 mass part of red mud. The specific preparation and application steps are as follows:

[0041] a) Heat the high-viscosity asphalt to 185°C. The original asphalt used in this study is high-viscosity asphalt, so it is necessary to ensure a higher temperature during the preparation and testing of the mortar, which is set at 185°C.

[0042] b) Heat the red mud in an oven at 180°C for 60±5 minutes to ensure that the filler is dry and at the same time close to the heating temperature of the asphalt.

[0043] c) Divide the filler into three parts, and add equal amounts to the asphalt. After adding the filler for the first time, stir it thoroughly with a glass rod, then turn on the asphalt shearer, and set the shear rate of the instrument to 4000r / min. After 5 minutes, add the second part of filler, continue to cut for 5 minutes, then add the third part of filler, and the...

Embodiment 2

[0046] The same preparation method as in Example 1 was adopted, except that: 1 mass part of domestic high-viscosity asphalt and 0.6 mass part of red mud were used to prepare modified asphalt mortar.

Embodiment 3

[0048] The same preparation method as in Example 1 was adopted, except that: 1 mass part of domestic high-viscosity asphalt and 0.9 mass part of red mud were used to prepare modified asphalt mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com