Antioxidant treatment method for isoprene rubber

An isoprene rubber and a processing method technology, applied in the field of the composition of conjugated diene homopolymers or copolymers, can solve the problem of limited durability of antioxidants, difficult to meet long-term use, high volatility and migration, etc. problems, to achieve the effect of reasonable steps, convenient processing and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

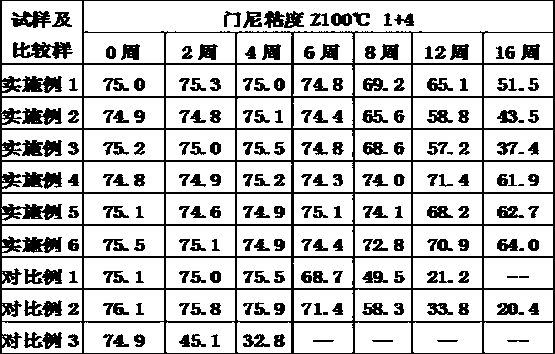

Examples

Embodiment 1

[0019] In the present embodiment, a kind of antioxidant treatment method of isoprene rubber, it goes through the following steps:

[0020] (1) 1 kg of antioxidant 1076, 0.7 kg of antioxidant 412S, 0.22 kg of antioxidant 1010 and 0.35 kg of antioxidant 38 were mixed, pulverized, and stirred uniformly to obtain a powdery composite antioxidant. The powdered compound antioxidant is granulated in a granulator, and the compound antioxidant of columnar particles is obtained through granulation;

[0021] (II) Dissolve the compound antioxidant of columnar particles obtained in step I in hexane to obtain a solution with a mass percentage of 20% and add according to the amount of compound antioxidant of columnar particles of 3.5 grams per kilogram of isoprene rubber Into the polyisoprene latex, adopt the hot water coagulation method to separate out the colloidal particles, and dehydrate the colloidal particles to obtain.

Embodiment 2

[0023] In the present embodiment, a kind of antioxidant treatment method of isoprene rubber, it goes through the following steps:

[0024] (I) 1 kg of antioxidant 1076, 0.5 kg of antioxidant 412S, 0.10 kg of antioxidant 1010 and 0.5 kg of antioxidant 38 were mixed, pulverized, and stirred evenly to obtain a powdery composite antioxidant. The powder Granulate the compound antioxidant in the granulator, and obtain the compound antioxidant of columnar particles through granulation;

[0025] (II) Dissolve the compounded antioxidant of the columnar particles obtained in step I in hexane to obtain a solution with a mass percentage of 15% and add the compounded antioxidant according to 2 grams of columnar particles per kilogram of isoprene rubber Into the polyisoprene latex, adopt the hot water coagulation method to separate out the colloidal particles, and dehydrate the colloidal particles to obtain.

Embodiment 3

[0027] In the present embodiment, a kind of antioxidant treatment method of isoprene rubber, it goes through the following steps:

[0028] (I) 1 kg of antioxidant 1076, 1.0 kg of antioxidant 412S, 0.40 kg of antioxidant 1010 and 0.2 kg of antioxidant 38 were mixed, pulverized, and stirred evenly to obtain a powdery composite antioxidant. The powder Granulate the compound antioxidant in the granulator, and obtain the compound antioxidant of columnar particles through granulation;

[0029] (II) Dissolve the compound antioxidant of the columnar particles obtained in step I in hexane to obtain a solution with a mass percentage of 25% and add according to the amount of the compound antioxidant of 5 grams of columnar particles per kilogram of isoprene rubber Into the polyisoprene latex, adopt the hot water coagulation method to separate out the colloidal particles, and dehydrate the colloidal particles to obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com