An emergency automatic plugging material

A plugging material and automatic technology, applied in the field of building materials, can solve the problems of no technical performance advantage, restricting application effect, slow setting and hardening, etc., to achieve the effect of automation and rapidity, high success rate, and improved impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

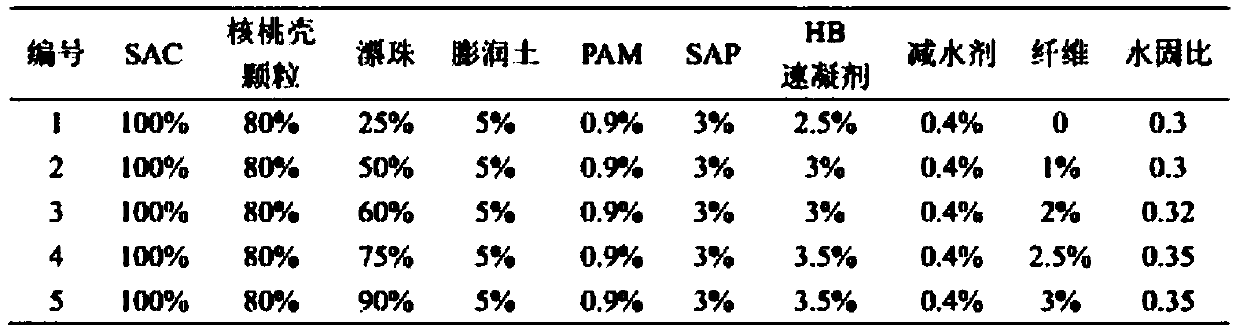

[0027] The specific parts by weight of each raw material in the examples are shown in Table 1.

[0028] Table 1 emergency automatic plugging material embodiment formula

[0029]

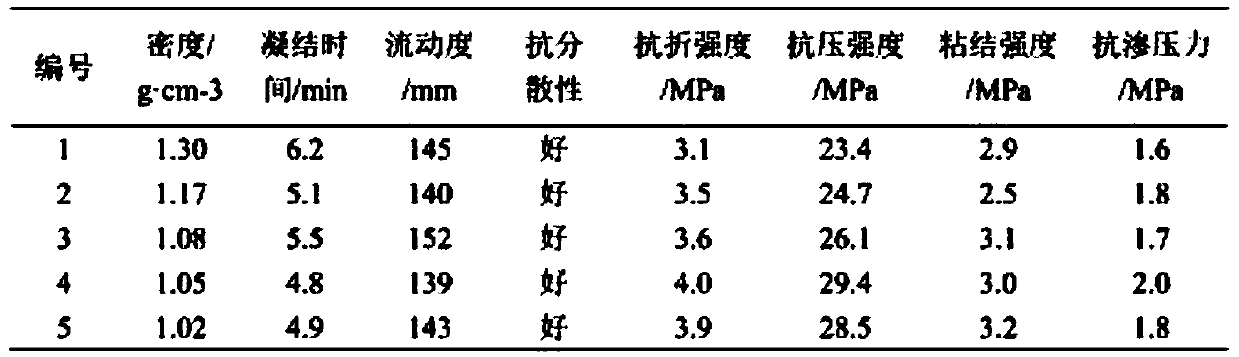

[0030] Table 2 shows the main performance index data of Examples 1-5 of the emergency automatic leak plugging material obtained according to the above-mentioned product preparation steps.

[0031] Table 2 Performance of emergency automatic plugging material embodiment

[0032]

[0033] It can be seen from Table 2 that the density of emergency automatic plugging materials with different dosages of floating beads can be changed in a wide range, and the setting time can also be adjusted by the dosage of accelerators. Examples 1-5 of the emergency automatic plugging material have good mechanical properties and impermeability, and the dispersion resistance and fluidity can also meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com