Concrete

A concrete and unit technology, applied in the field of concrete, can solve the problems of poor corrosion resistance and easy cracks, and achieve the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

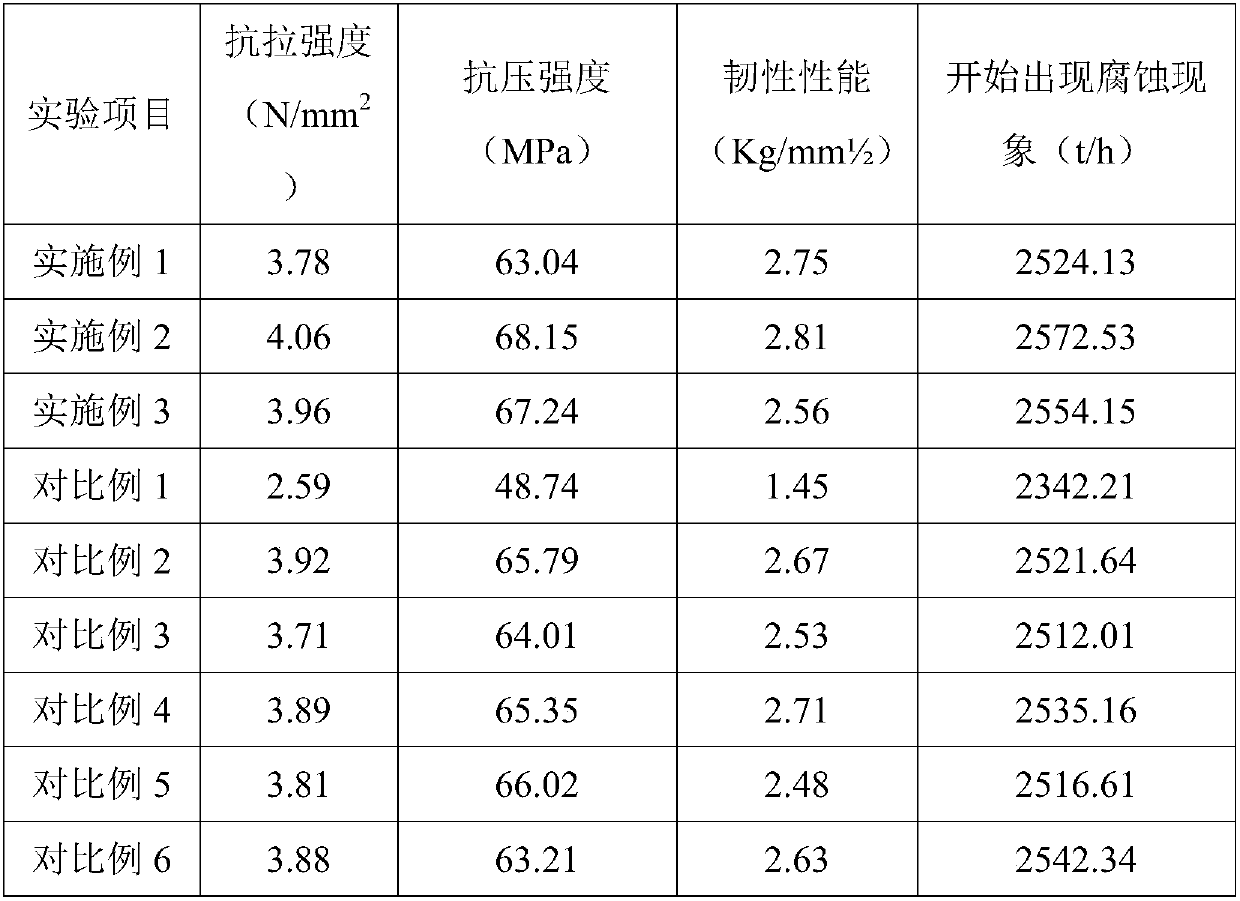

Examples

preparation example Construction

[0013] The preparation method of described concrete comprises the following steps:

[0014] S1, ingredients: firstly mix cement, sand, stone, water, paper rebar, rice straw, hemp knife, and polypropylene fiber according to the weight ratio to obtain a mixed homogeneous material;

[0015] S2. Modified material: polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-( Mix hydroxymethyl)-1,3-propanediol ether, SJ-101 resin, polyphenol novolac, and zinc trimerized acrylate according to the weight ratio, stir for 4-6min, then raise the temperature to 85-92°C rapidly, and the stirring modification time For 15-30min, the modified material is obtained;

[0016] S3. Stirring: add the mixed homogeneous material prepared in step S1 into water in parts by weight, stir for 8-10 minutes, then add the modified material prepared in step S2, and stir for another 10-15 minutes to prepare concrete.

Embodiment 1

[0019] A kind of concrete, by weight, comprises following raw material: 122 parts of cement, 25 parts of sand, 20 parts of stone, 250 parts of water, 16 parts of paper tendon, 18 parts of rice straw, 12 parts of hemp knife, 8 parts of polypropylene fiber, 4 parts of polyphenol novolac, 12 parts of polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)-1,3- 6 parts of propylene glycol ether, 8 parts of SJ-101 resin, 3 parts of zinc trimer acrylate;

[0020] The preparation method of described concrete comprises the following steps:

[0021] S1, ingredients: firstly mix cement, sand, stone, water, paper rebar, rice straw, hemp knife, and polypropylene fiber according to the weight ratio to obtain a mixed homogeneous material;

[0022] S2. Modified material: Polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl base)-1,3-propanediol ether, SJ-101 resin, polyphenol novolac, and zinc trimerized acrylate were mixed in propo...

Embodiment 2

[0025] A kind of concrete, by weight, comprises following raw material: 140 parts of cement, 28 parts of sand, 25 parts of stone, 350 parts of water, 18 parts of paper tendon, 22 parts of rice straw, 15 parts of hemp knife, 12 parts of polypropylene fiber, 6 parts of polyphenol novolac, 18 parts of polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)-1,3- 8 parts of propylene glycol ether, 10 parts of SJ-101 resin, 5 parts of zinc trimer acrylate;

[0026] The preparation method of described concrete comprises the following steps:

[0027] S1, ingredients: firstly mix cement, sand, stone, water, paper rebar, rice straw, hemp knife, and polypropylene fiber according to the weight ratio to obtain a mixed homogeneous material;

[0028] S2. Modified material: Polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl base)-1,3-propanediol ether, SJ-101 resin, polyphenol aldehyde, and zinc trimerized acrylate were mixed accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com