Aluminum alloy assembled twin-hull high-speed target vessel

An assembly type, aluminum alloy technology, applied in the direction of hull, ship construction, hull frame, etc., can solve the problems of high cost, difficult to reuse, easy to sink into water, etc., to ensure quality and reliability, reduce structural strength, improve The effect of running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

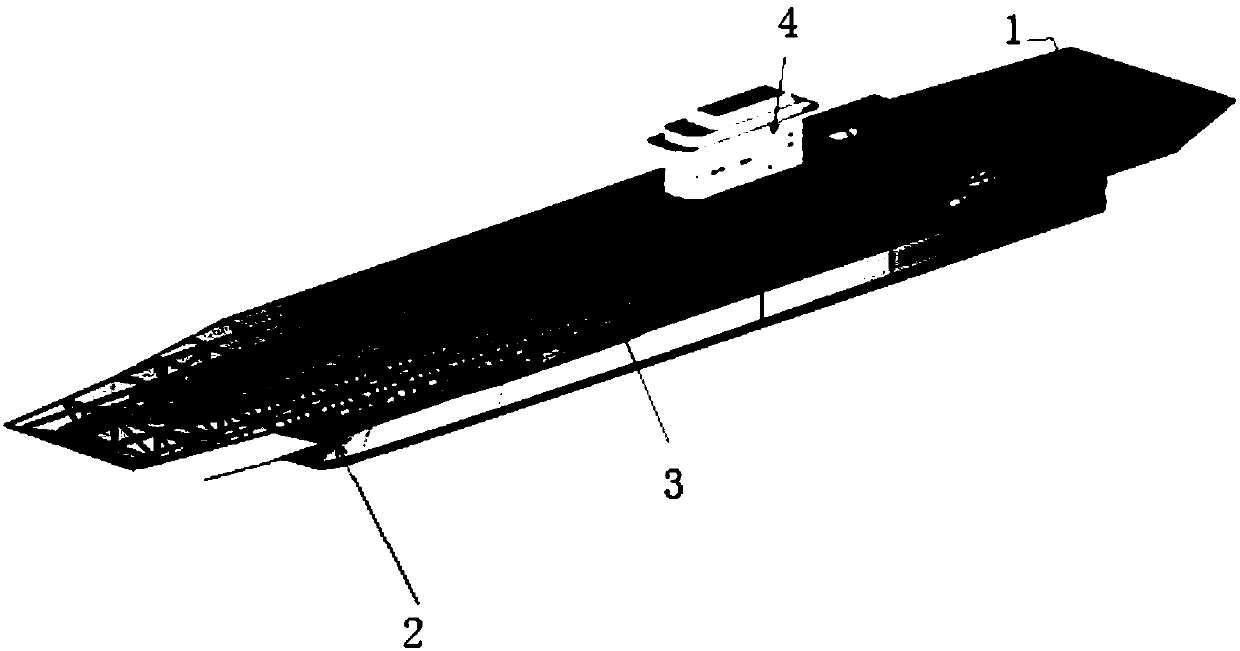

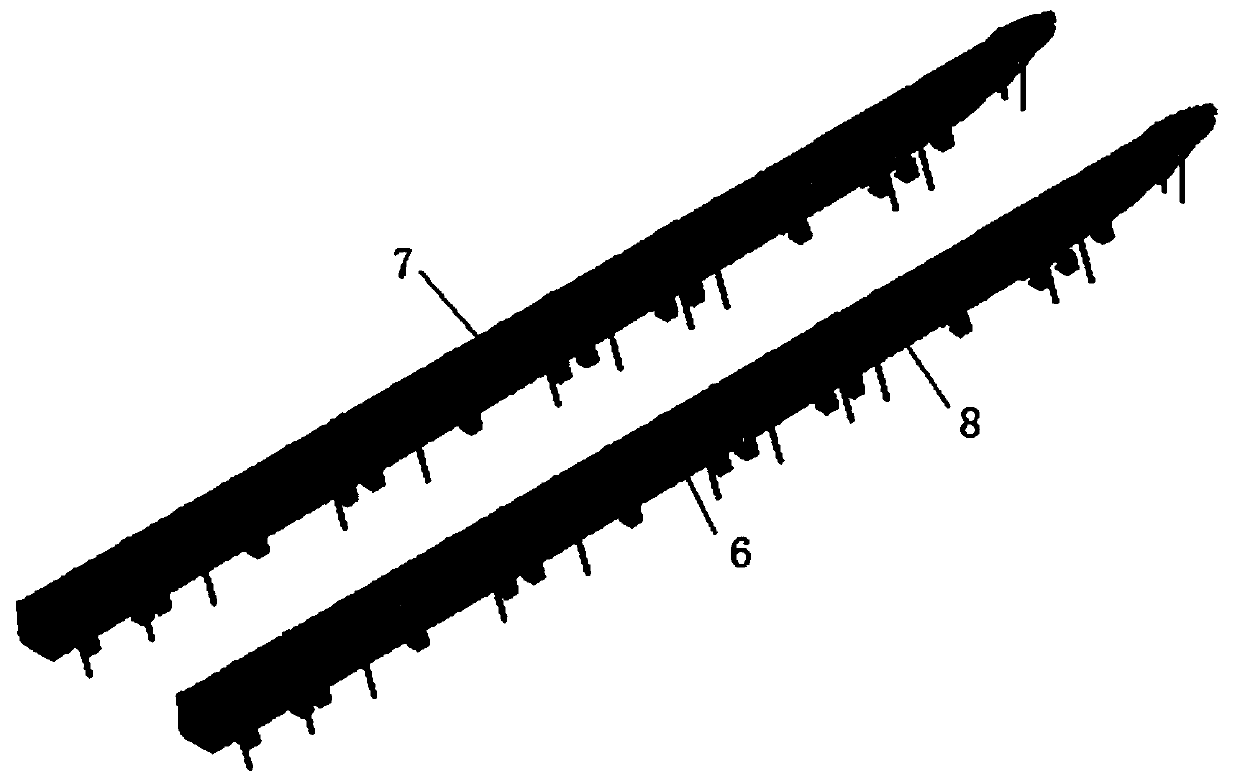

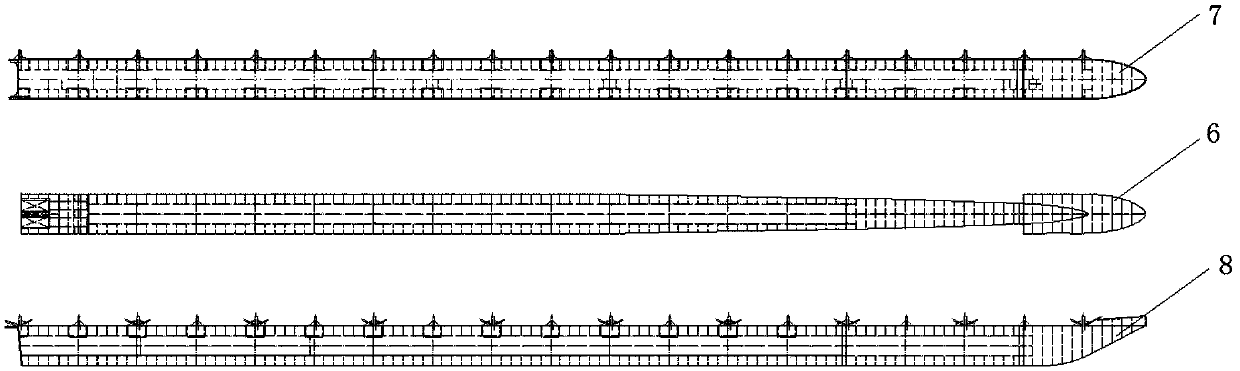

[0028] Such as figure 1 As shown, a light-weight high-speed target ship of an assembled aluminum alloy double body. The target ship is about 75 meters long, 16 meters wide, and 3.5 meters high (excluding island 4). It is mainly composed of three parts: hull structure, power propulsion system and navigation control system. The hull structure mainly includes sheet body 2, truss structure 3, target ship deck 1 and ship island 4, wherein sheet body 2 is spliced from end to end of partition cabins of specific specifications, and the overall shape is streamlined. Sheet body 2 includes the first sheet The body 2-1 and the second sheet body 2-2, the first sheet body 2-1 and the second sheet body 2-2 have the same struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com