Manufacturing method of recombined decorative veneer with rhombus interweaving pattern

A technology for reorganizing decoration and manufacturing methods, which is applied in the joining of wooden veneers, manufacturing tools, adhesive application devices, etc., can solve the problems of manufacturing rhombus interwoven patterns, reorganizing decorative veneers, and no manufacturing methods, etc., and achieves a modern and fashionable appearance. , easy operation, outstanding appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

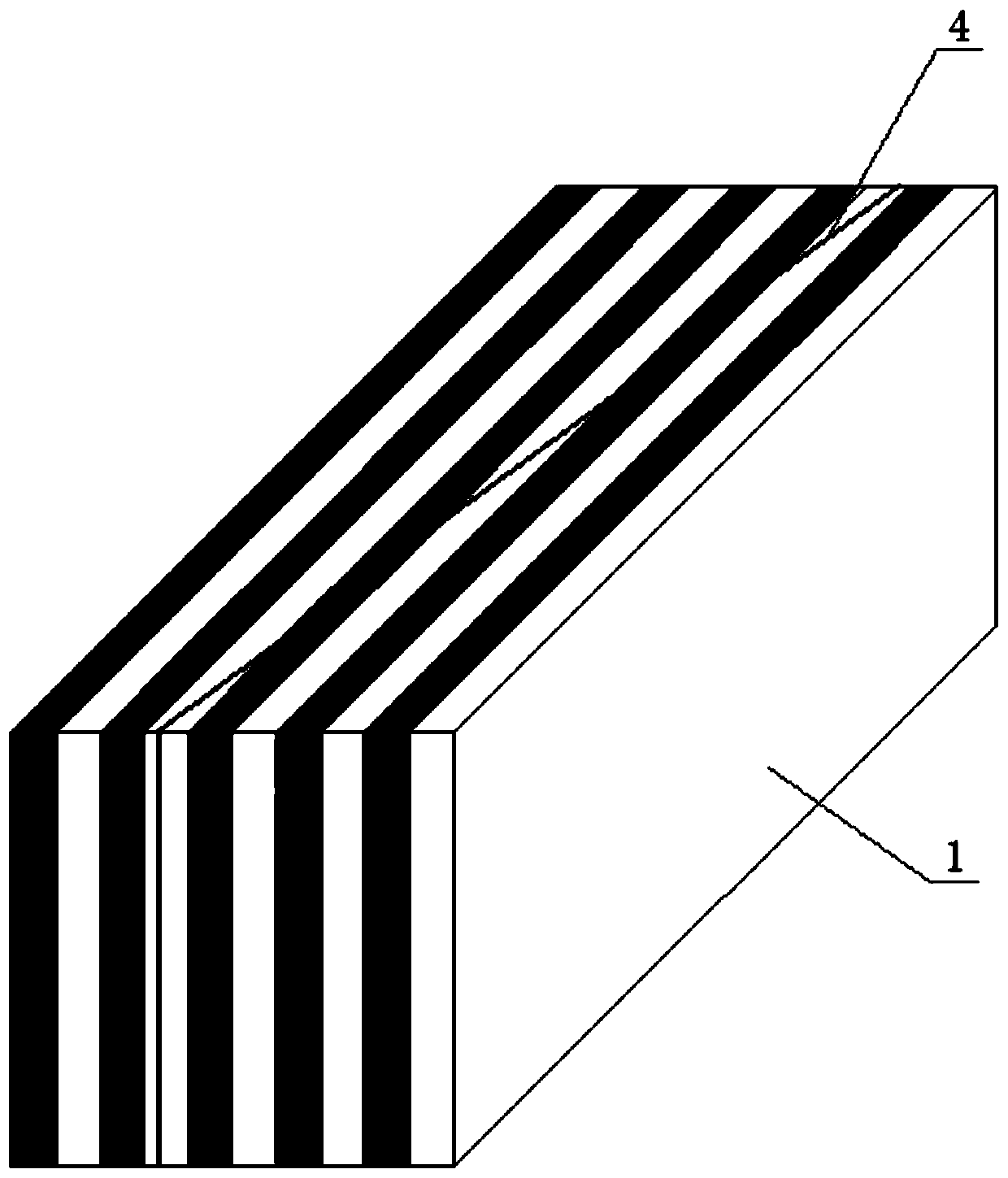

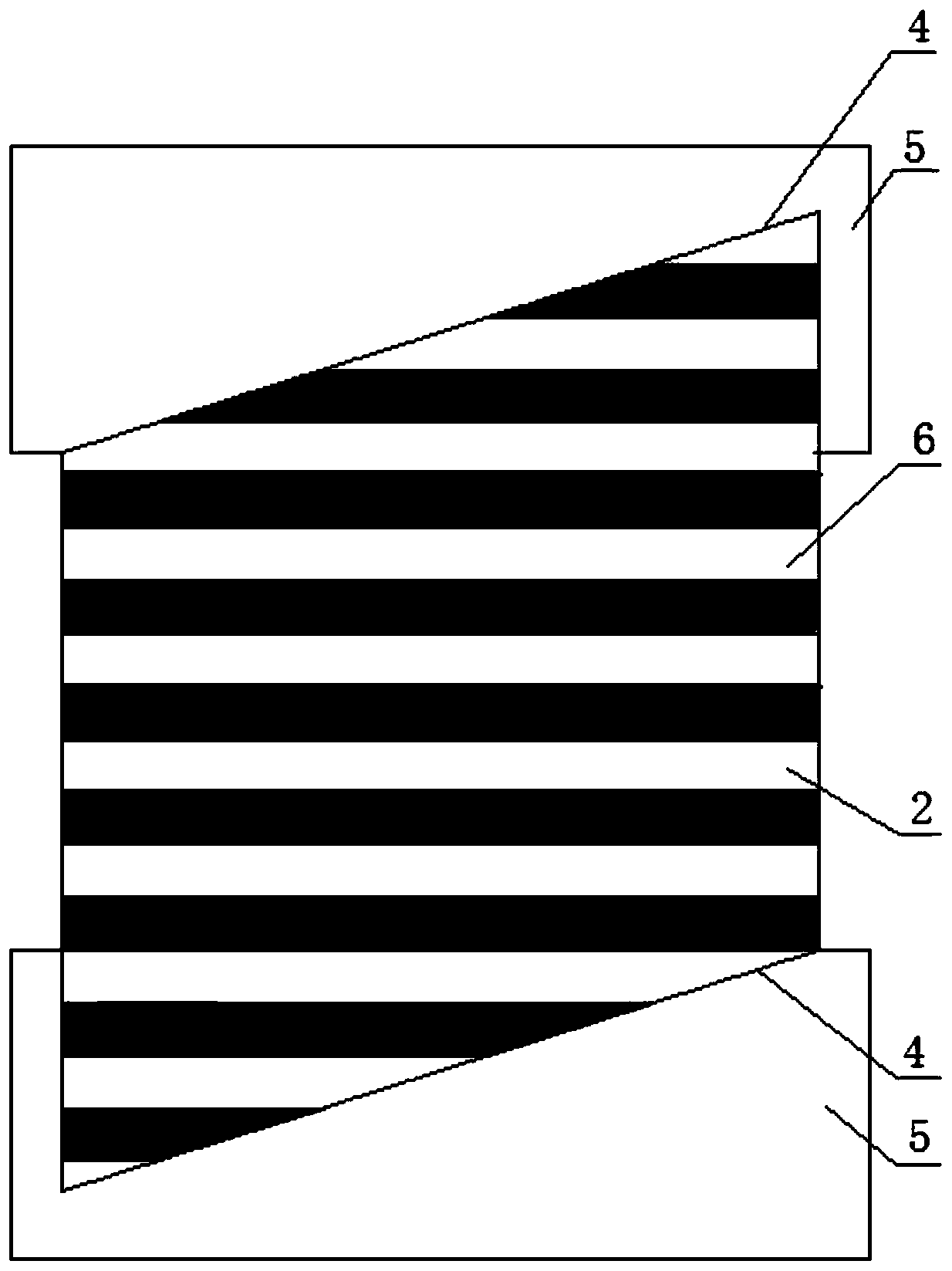

[0042] Embodiment 1: In the rhombus interweaving pattern designed in this embodiment, the side length of the rhombus is 40 mm, and the sawing angle of one round is 30°. The manufacturing method of the recombined decorative veneer with the rhombus interweaving pattern is as follows:

[0043] 1. A round of billets: Reddish-brown and light yellow poplar dyed veneer with veneer core uniform in color, wood defects removed, length 2440mm, veneer moisture content 45% as raw material veneer.

[0044] In the rhombus interweaving pattern designed in this embodiment, the side length of the rhombus is 40 mm, and the sawing angle of one round is 30°. The distance between two opposite sides of the rhombus, that is, the thickness of the blank of the same color, is calculated according to the following formula: b=Sinα×a, where a is a rhombus Side length, α is a round sawing angle; b=Sin30°×40mm=20mm in this embodiment.

[0045] In this embodiment, 25 reddish-brown and light yellow veneers wit...

Embodiment 2

[0059] Embodiment 2: In the rhombus interweaving pattern designed in this embodiment, the side length of the rhombus is 40 mm, and the sawing angle of one round is 30°, then the manufacturing method of the recombined decorative veneer with the rhombus interweaving pattern is as follows:

[0060] 1. A round of billets: Reddish-brown, light yellow and light brown poplar dyed veneer with veneer surface core uniform in color, wood defects removed, length 2440mm, veneer moisture content 45% is used as raw material veneer.

[0061] In the rhombus interweaving pattern designed in this embodiment, the side length of the rhombus is 40 mm, and the sawing angle of one round is 30°. The distance between two opposite sides of the rhombus, that is, the thickness of the blank of the same color, is calculated according to the following formula: b=Sinα×a, where a is a rhombus Side length, α is a round sawing angle; b=Sin30°×40mm=20mm in this embodiment.

[0062] In this example, 25 red-brown, ...

Embodiment 3

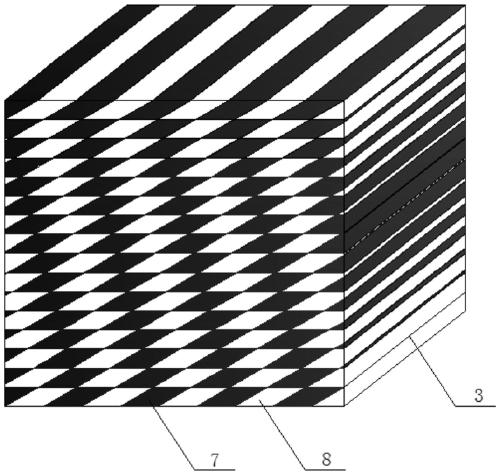

[0073] Embodiment 3: In the diamond-shaped interweaving pattern designed in this embodiment, the distance between the two opposite sides of the rhombus is 30mm, and the length of the rhombus side is 40mm. The manufacturing method of the rhombus-shaped interweaving pattern recombined decorative veneer is as follows:

[0074] 1. A round of blanks: the veneer core is uniform in color, wood defects are removed, the length is 1500mm, and the veneer moisture content is 42% light brown veneer and dark brown veneer as raw material veneer. 30 sheets of light brown veneer and dark brown veneer each with a thickness of 1.0mm are stacked along the grain to form a light brown same-color blank and a dark brown same-color blank, each with a thickness of 30mm; a light brown same-color blank and A dark brown billet of the same color is stacked along the grain to form a unit billet, and the thickness of the unit billet is 60mm.

[0075] In the rhombus interweaving pattern designed in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com