Thermal forming insert for stamping die

A stamping die and thermoforming technology, which is applied in the field of thermoforming inserts, can solve problems such as lack of sealing equipment, prolonging mold forming time, loss of compressed air heat, etc., to solve internal stress unevenness, shorten thermoforming time, The effect of uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

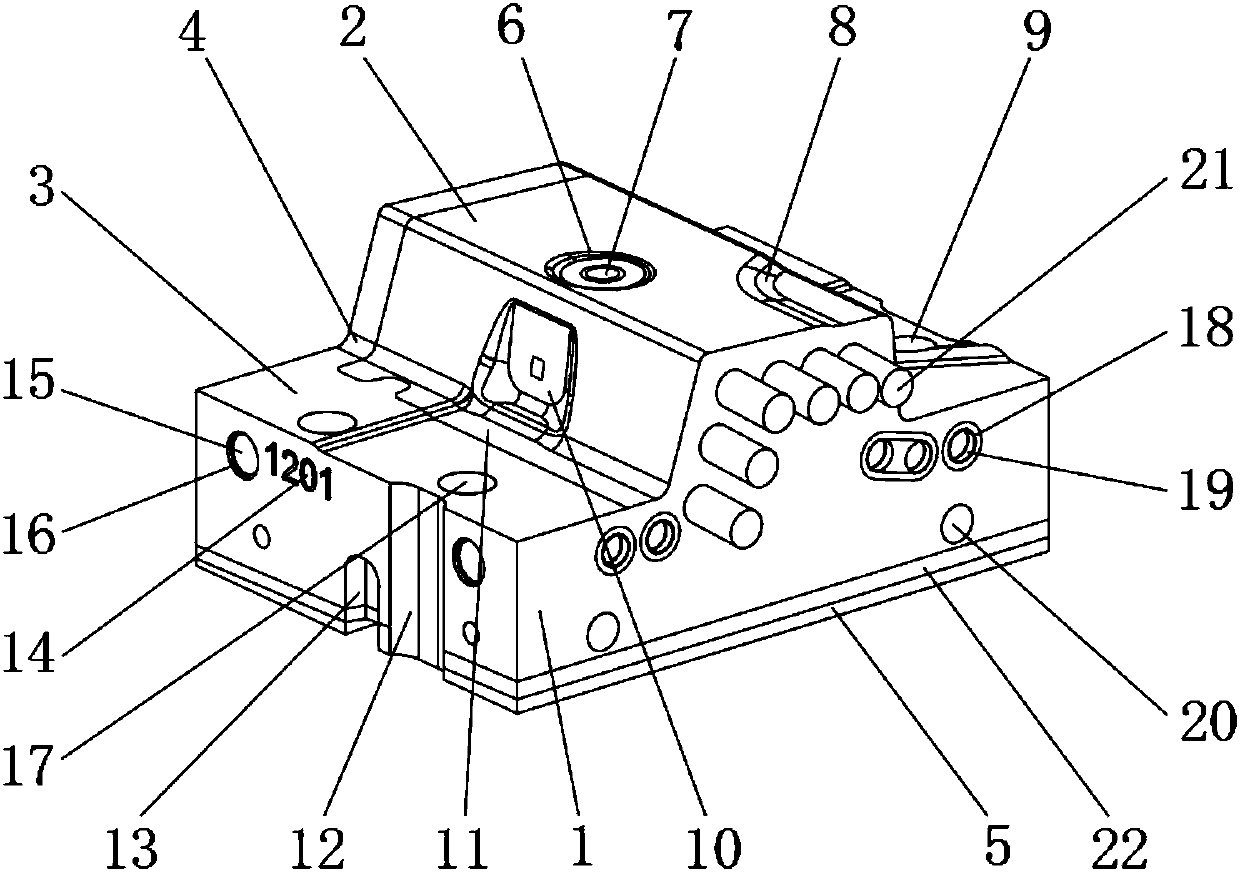

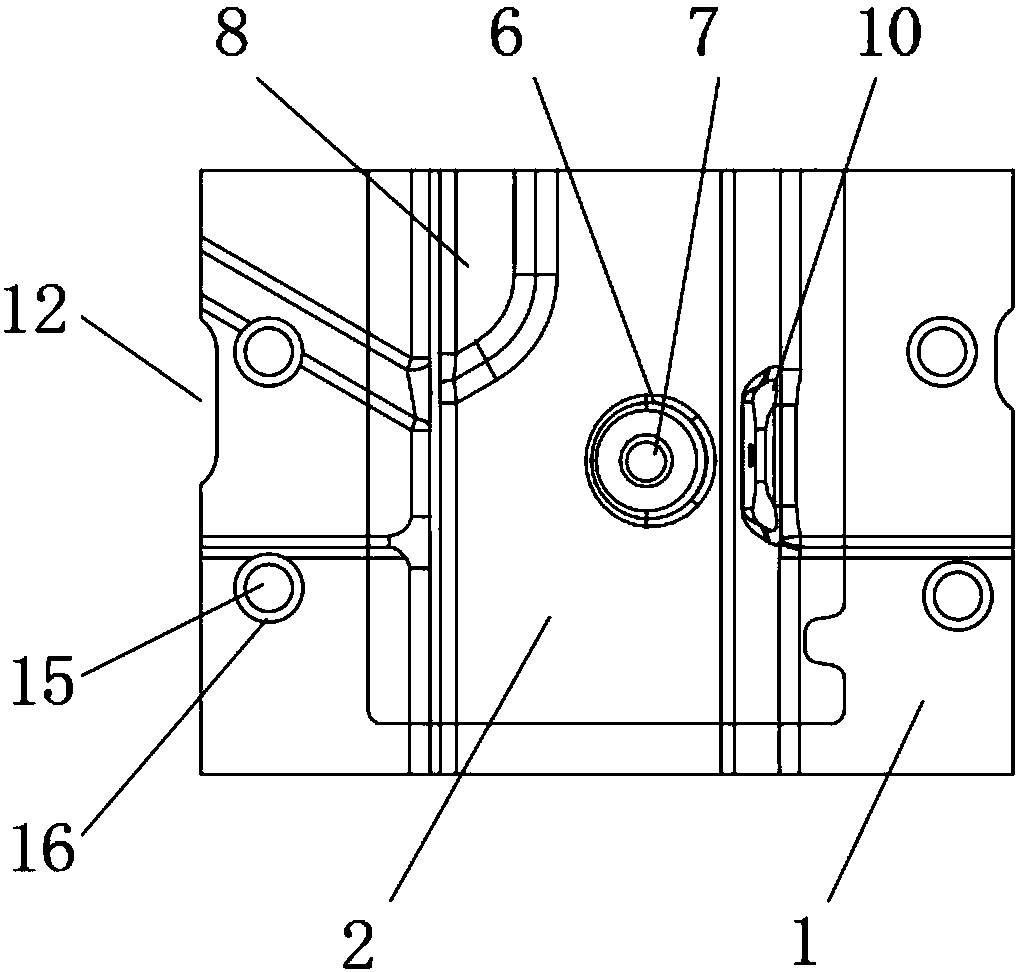

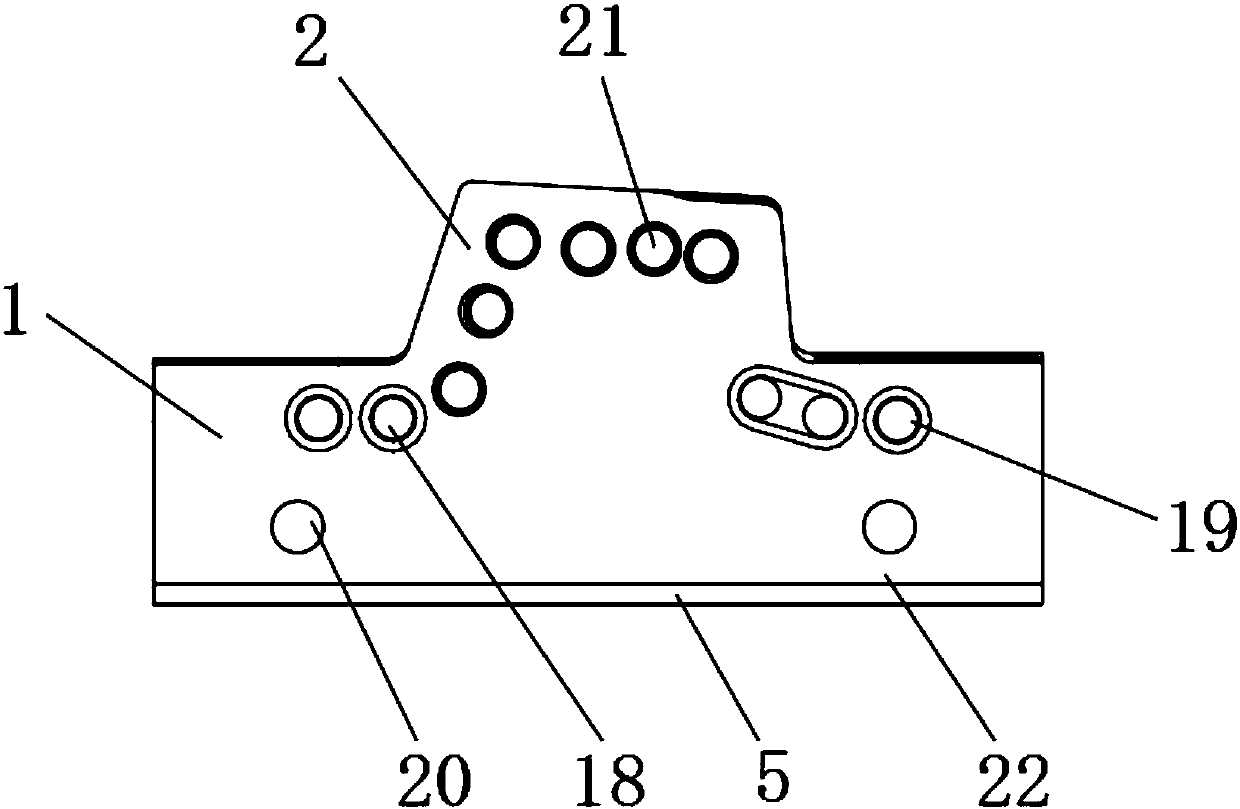

[0020] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a thermoforming insert for a stamping die, including an insert body 1, a movable mold 2, a fixed mold 3, a movable mold backing plate 4, a fixed mold bottom plate 5, and a positioning ring 6 , nozzle 7, fixed block 8, guide post 9, main channel bushing 10, hot runner plate 11, limit groove 12, fixed groove 13, digital mark 14, compressed gas through hole 15, sealing rubber ring 16, heating Device hole 17, fixing screw hole 18, internal thread 19, cooling air passage hole 20, heating rod 21 and heat insulation plate 22, a movable mold 2 is arranged above the insert body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com