Air-suspending dispersion dry separation belt magnetic separator

An air suspension and magnetic separator technology, which is applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems that materials cannot be soaked in water or water, cannot use wet magnetic separation, and high equipment and production costs. The effect of reducing inclusions or wrapping, reducing self-adhesion, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

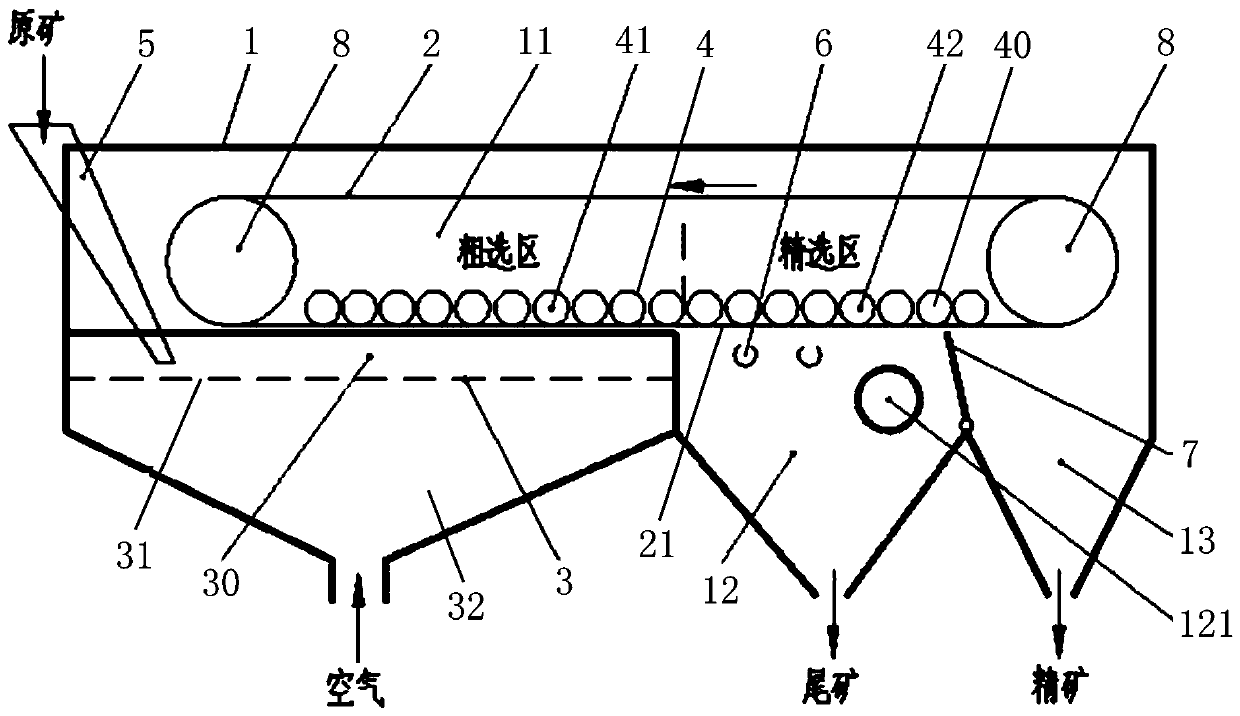

[0019] Such as figure 1 As shown, the air-suspension dispersed dry-separation magnetic separator of the present embodiment includes a housing 1 with a closed inner cavity 11, and a non-magnetic conductive endless belt 2 driven by a driving device is installed in the closed inner cavity 11. The lower part of the magnetically conductive annular belt 2 is the magnetic separation section 21, and the closed inner cavity 11 is provided with a conveying trough 3, a non-magnetic product receiving bucket 12 and a magnetic product receiving bucket located below the magnetic selection section 21 and arranged in sequence along the running direction of the magnetic selection section 21. 13. The conveying trough 3 and the magnetic separation section 21 form a conveying channel 30 for conveying materials to the non-magnetic product receiving bucket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com