Strip pack

A strip and packaging technology, applied in packaging, household packaging, food packaging, etc., can solve the problems of unsatisfactory durability, complexity, and cost, and achieve the effect of good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 3 approach

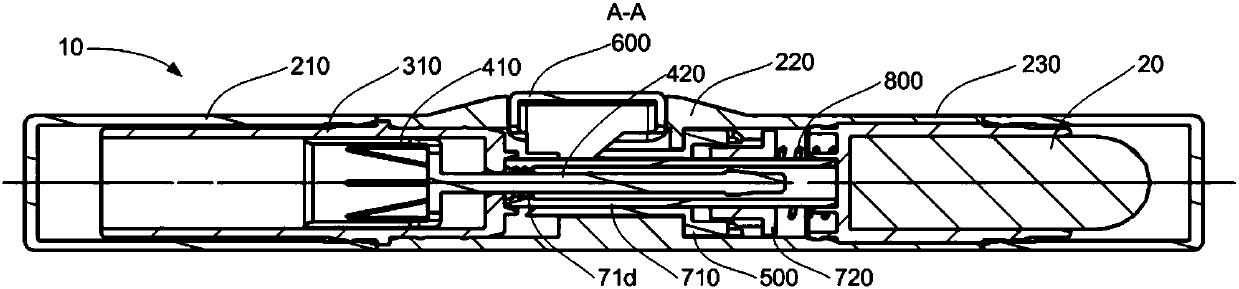

[0105] According to the third embodiment of the present invention, the actuator 4600 includes an actuator body 4610 , a push rod 4620 and a hinge 4630 . However, it is understood that even the hinge 4630 can be omitted, as long as the push rod is arranged obliquely between the actuation body and the drive member, so that the translational movement of the actuation body is perpendicular to the longitudinal direction of the stick pack It is only necessary that the translational movement parallel to the longitudinal direction of the stick-shaped packaging of the driving member can be mutually converted. For example, a groove may be provided on the actuation body 4610 to receive the rear end of the push rod 4620 opposite the front end 4623 .

[0106] With the novel actuator 4600 according to the present invention, the user's pressing stroke can be much longer than the desired content extension. Since the required extension of the content is generally small, the lengthening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com