A winding machine and winding method for double-outer enameled wire outlets of a motor

A winding method and enameled wire technology, which are applied in the field of double outer enameled wire outlet winding machines and winding fields of motors, can solve the problems of reducing the overall height of the motor, poor and disadvantageous electromagnetic performance of the motor, and avoid disassembly and reassembly. The effect of being scratched and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

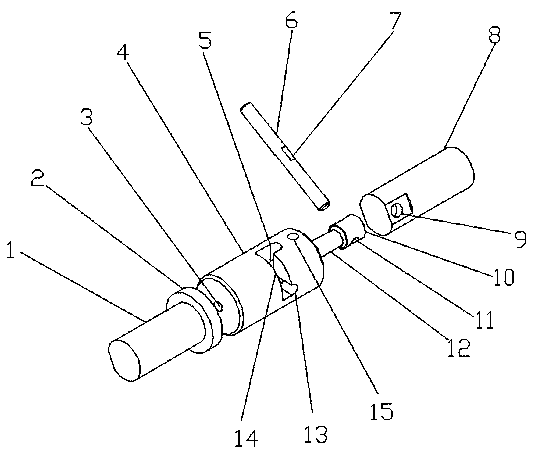

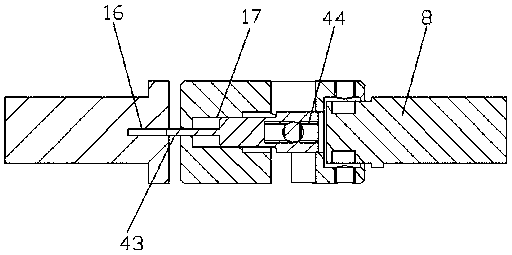

[0026] As a first embodiment of the present invention, the depth of the sleeve guide groove 17 is equal to the length of the mandrel guide shaft 12 .

[0027] As a second embodiment of the present invention, the depth of the sleeve guide groove 17 is greater than the length of the mandrel guide shaft 12 .

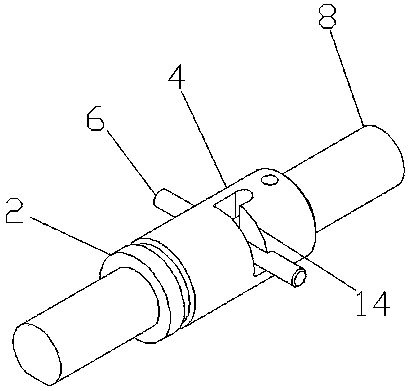

[0028] As a first embodiment of the present invention, a positioning groove 7 is processed in the middle of the rod body of the rotating rod 6, and the positioning groove 7 is a plane groove.

[0029] As a second embodiment of the present invention, a counterbore is processed in the middle of the rod body of the rotating rod 6 .

[0030] As a first embodiment of the present invention, the winding core on the mandrel 10 is cylindrical.

[0031] As a second embodiment of the present invention, the winding core on the mandrel 10 is square.

[0032] The length of the core removal groove 5 is equal to the length that the mandrel 10 protrudes from the core hole 3 , and the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com