Formation device of full-automatic fan motor assembly equipment

A technology of fan motor and assembly equipment, applied in electromechanical devices, manufacturing motor generators, metal processing equipment, etc., can solve the problems of high heat, small torque, low efficiency of manual assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

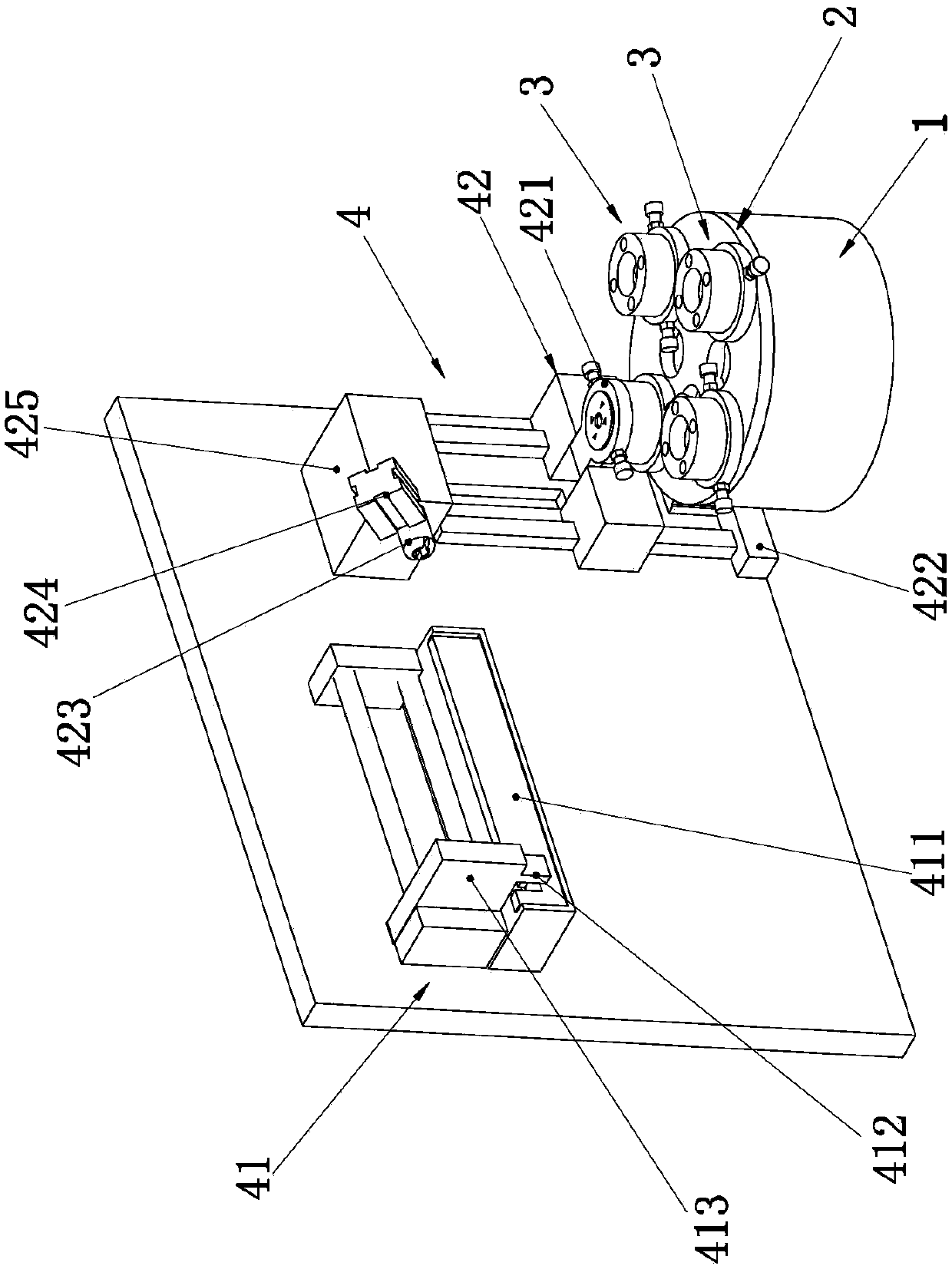

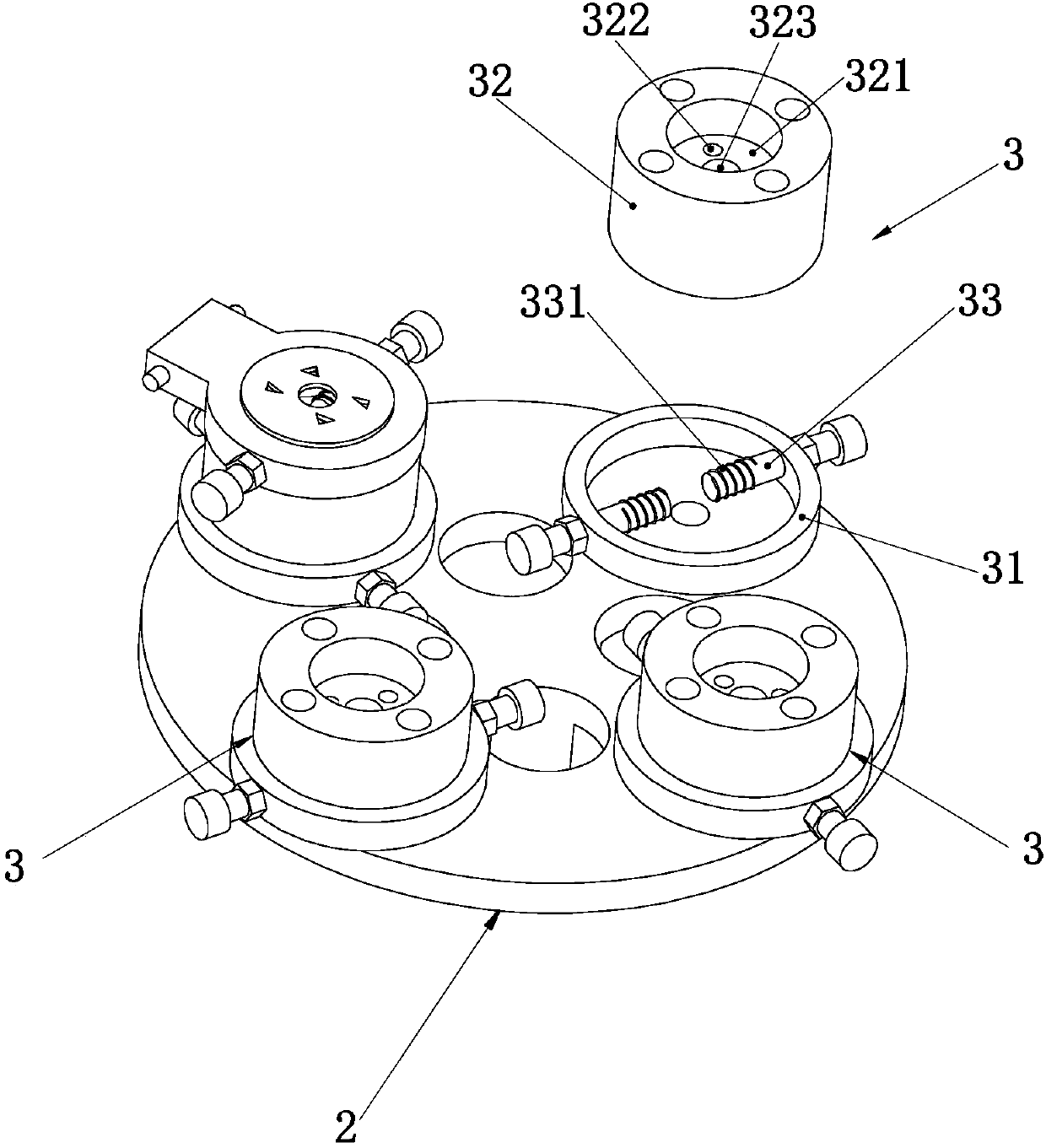

[0016] like figure 1 , figure 2 The molding device of a fully automatic fan motor assembly equipment shown includes a body 1, a turntable 2 erected on the body 1 and capable of rotating along the body, a number of assembly fixtures 3 evenly distributed on the turntable 2, and a An assembly device 4 can be used to assemble the workpiece in the assembly fixture 3 . The assembly device 4 includes a rotor conveying assembly, a rotating shaft conveying assembly 41 and a rotating shaft assembling assembly 42 arranged on the outer edge of the turntable 2 in sequence. In the above solution, the rotor is transported to the turntable 2 by the rotor transport assembly, and the turntable 2 transports the assembly jig 3 with the rotor to the shaft device assembly 42 through rotation. At this time, the shaft transport assembly 41 outputs the shaft, and then passes through the shaft assembly assembly 42 The rotating shaft and the rotor are assembled, and the assembly process does not requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com