Vacuum liquid-cooled coupling heat management system of power battery and operating method

A power battery and management system technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of occupying the battery system, energy waste, and reducing the battery life of the power battery system, so as to improve battery life and life, The effect of reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

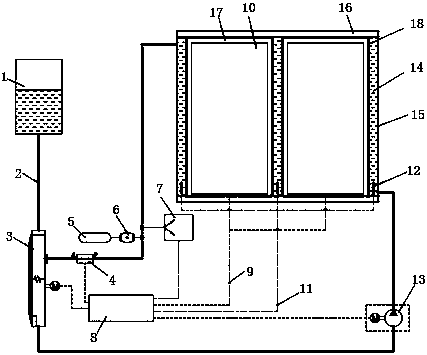

[0022] Refer to attached figure 1 The specific implementation manner of the present invention is introduced.

[0023] Such as figure 1 As shown, a vacuum liquid cooling coupled thermal management system for a power battery includes a battery pack 17, a hollow cooling plate 15 arranged on both sides of the battery pack 17, and a liquid cooling circuit 2 with a hydraulic pump 13 communicating with the cooling plate 15 And the battery control unit 8; the liquid cooling circuit 2 is connected with a temperature controller 3, a solenoid valve 4, a ventilator and a vacuum pump 7, the temperature controller 3 is connected with a coolant backup tank 1, and the ventilator includes a storage tank with a filter screen The air tank 5 and the intake valve 6 connected to the liquid cooling circuit 2; the temperature controller 3 is provided with a motor.

[0024] The front and rear ends of the battery pack 17 are provided with metal vacuum-type fixed end plates 16 for fixing the battery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com