Apparatus and method for correcting direct drive generator model

A generator model and model correction technology, which is applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve the problem of low model accuracy, improve product quality, reduce enterprise costs, and reduce cycle times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

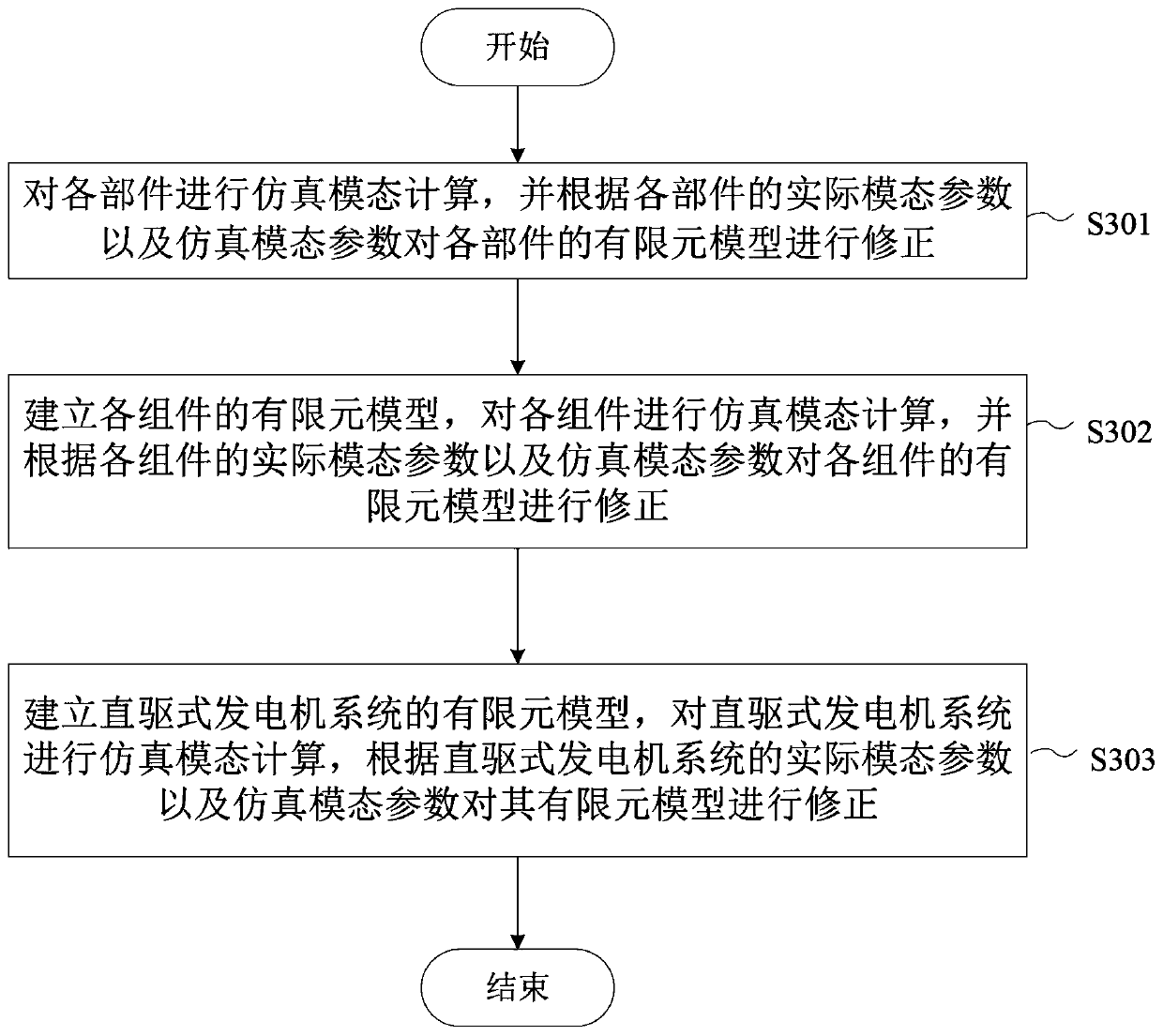

[0033] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

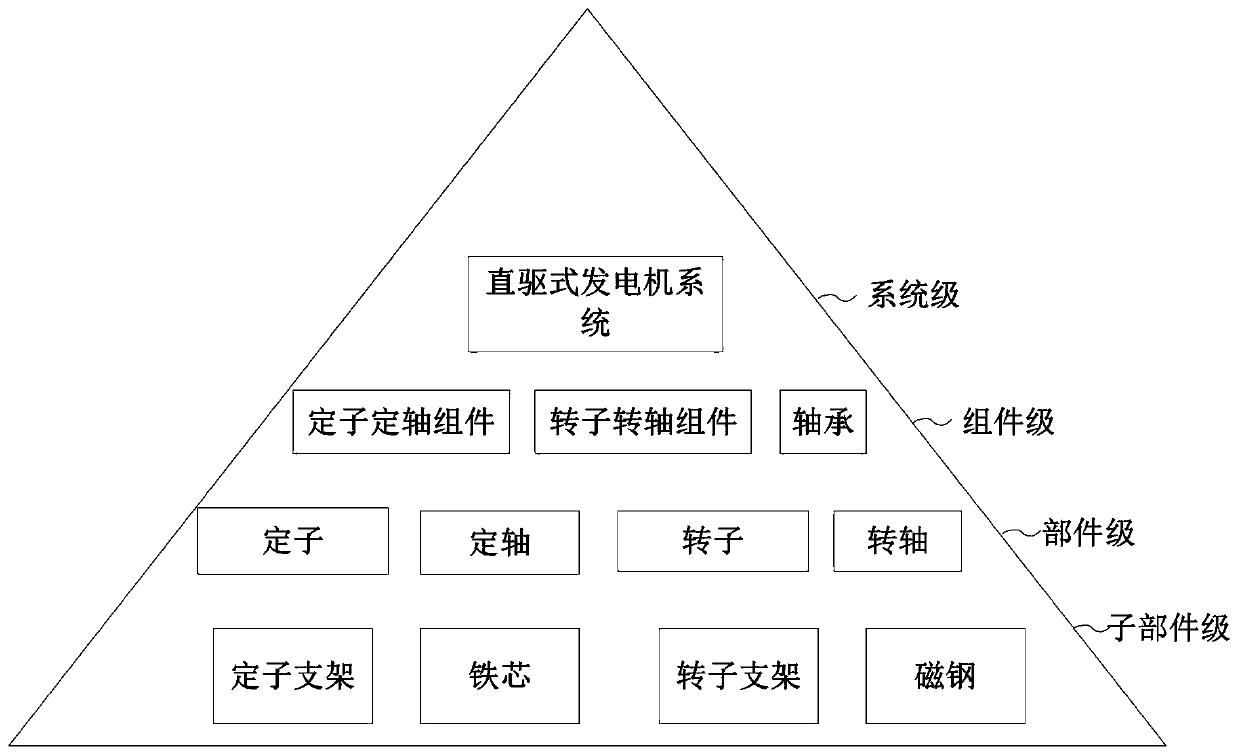

[0034] figure 1 is a schematic diagram showing the structure of each level of the direct drive generator according to the embodiment of the present invention. Such asfigure 1 As shown, the sub-component level structure includes stator bracket, iron core, rotor bracket, magnetic steel, etc., the component level structure mainly includes stator, fixed shaft, rotor, rotating shaft, etc., and the component level structure includes stator and fixed shaft. The stator and fixed shaft assembly, the rotor shaft assembly composed of the rotor and the shaft, and bearings, etc., the system-level structure is a direct-drive generator system.

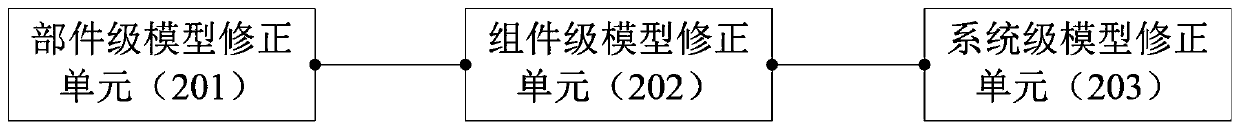

[0035] figure 2 is a block diagram showing a correction device of a direct drive generator model according to an embodiment of the present invention. refer to figure 2 , the correction device of the direct-drive generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com