Construction technology for huge isolated boulders of alluvial granite in diaphragm wall construction

A construction technology and anti-seepage wall technology, applied in blasting and other directions, can solve the problems of difficult to guarantee construction period, rapid wear of drilling tools, and leakage of slurry in collapsed holes, so as to avoid unnecessary disturbance, reduce production time, and save construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

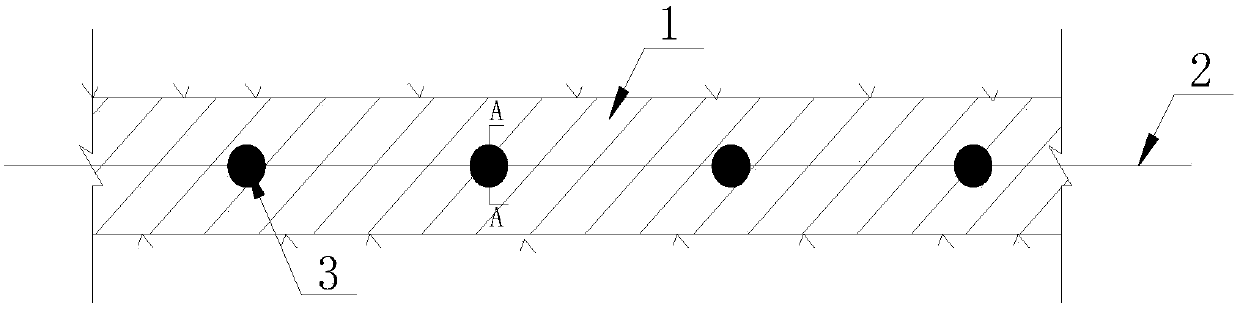

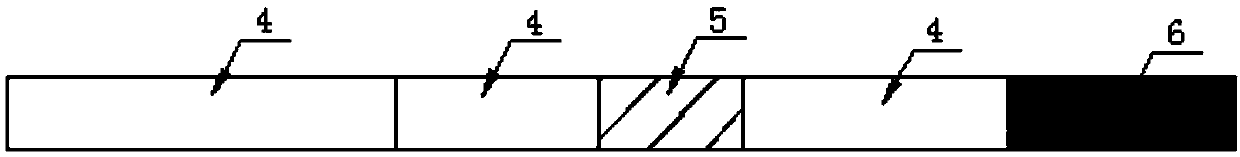

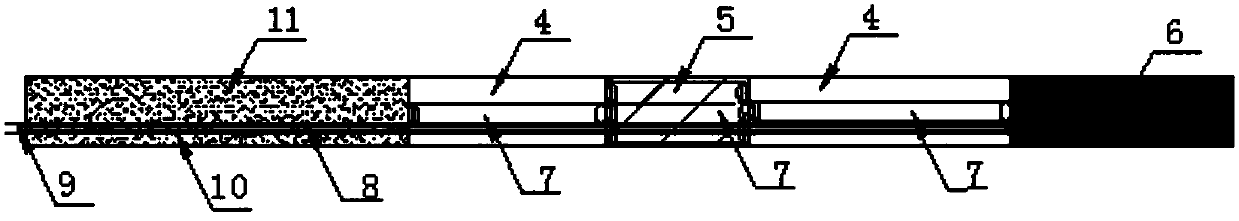

[0029] combine Figure 1 to Figure 3 .

[0030] A construction technique for alluvial granite boulders in the construction of cutoff walls, comprising the following process steps:

[0031] 1) Drilling preparation: including measuring and releasing the axis of the anti-seepage wall, laying out pre-exploration and pre-explosion drilling holes along the axis of the anti-seepage wall at a distance of 2.0m, using steel nails and lime to mark and locate the drilling center, and preparing and positioning the drilling machine;

[0032] 2) Drilling equipment: the present invention adopts Ingersoll Rand KR805-1 type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com