Disc spring loading type wedge-shaped dynamic sealing structure for ultralow-temperature device

A dynamic sealing structure, wedge-shaped sealing technology, applied in the direction of engine sealing, shaft sealing, valve device, etc., can solve the complex molding process of large-size bellows components, light weight, inconsistent high reliability requirements, and large sealing device volume, etc. problems, to achieve the effect of saving axial installation space, shortening production cycle, long life and high reliability sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] The present invention adopts disc spring-loaded wedge-shaped dynamic sealing structure, which can effectively replace the traditional bellows seal, realize the miniaturization, light weight and high reliability of the dynamic sealing device, and at the same time carry out structural innovation design for the dynamic sealing technology of the valve shaft; the dynamic sealing structure is applied to Ultra-low temperature liquid hydrogen and liquid oxygen environment, the ambient temperature is 20-500K.

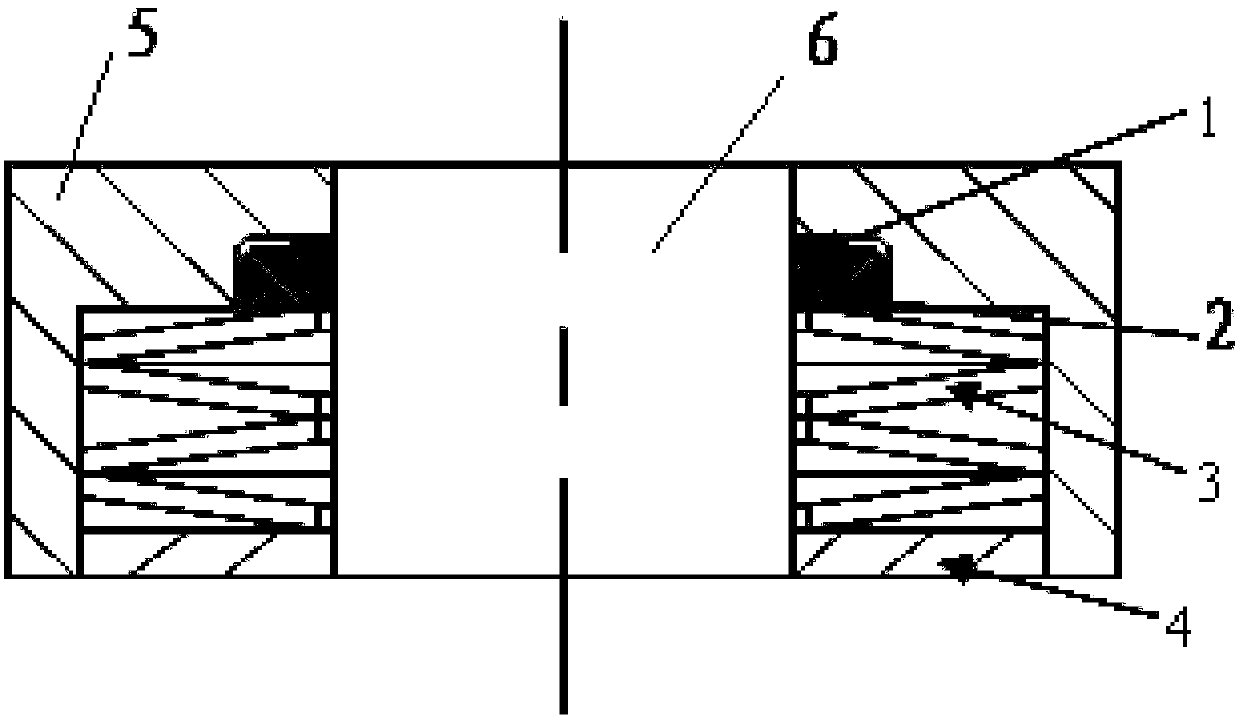

[0021] Such as figure 1 Shown is a schematic diagram of a disc spring-loaded wedge-shaped dynamic seal structure. It can be seen from the figure that the disc-spring-loaded wedge-shaped dynamic seal structure for ultra-low temperature devices is characterized in that it includes a non-metallic wedge-shaped seal ring 1, a metal retaining rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com