An all-electric rotary actuation device with high power-to-weight ratio integrated and large load

A technology of rotary actuation and power-to-weight ratio, applied in transmission devices, electromechanical devices, transmission device parts, etc., can solve the problems of complex oil circuit and supporting equipment, low power density, low integration, etc., and save axial installation The effect of saving space, improving carrying capacity and reducing the volume of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

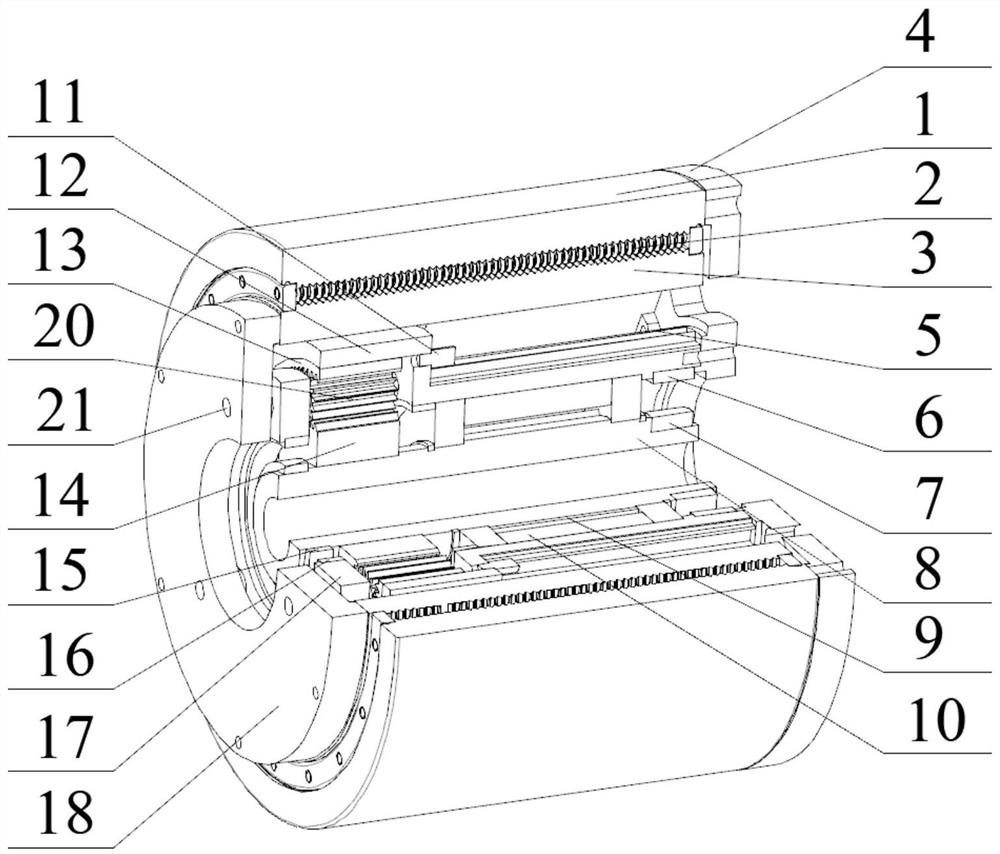

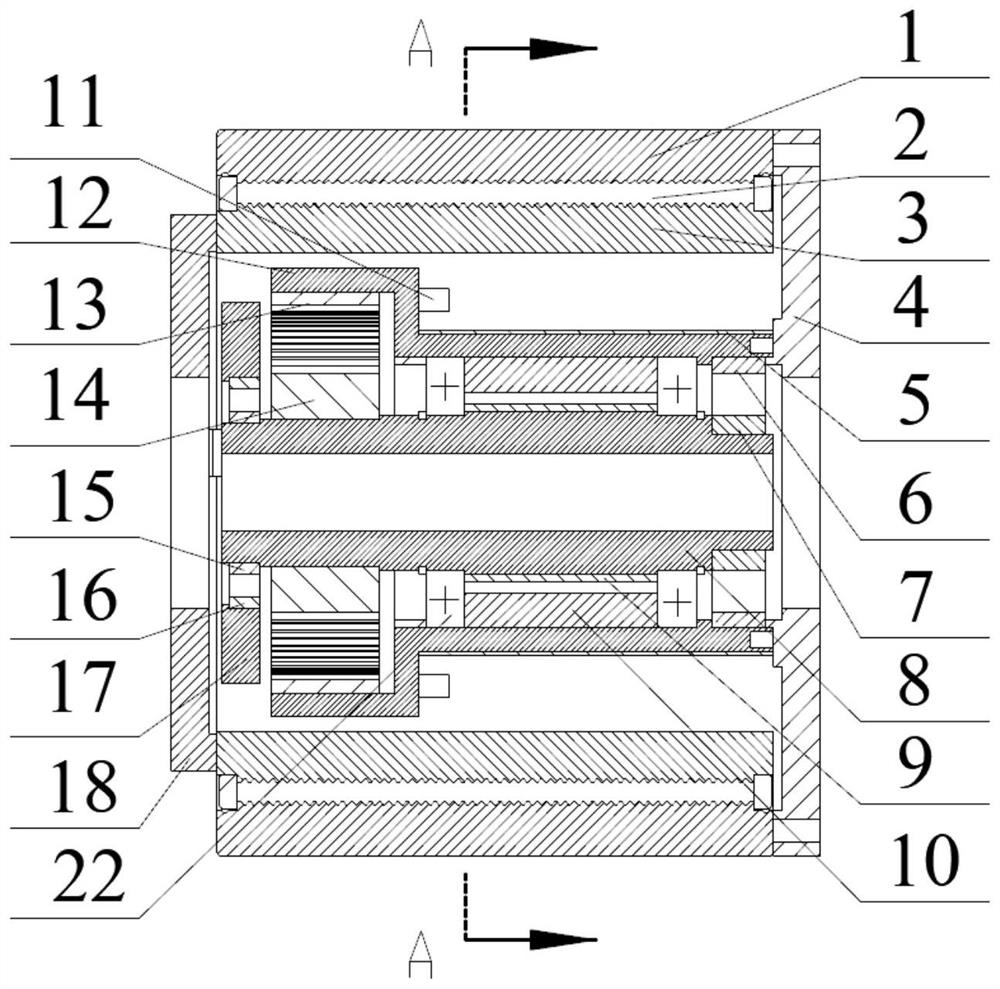

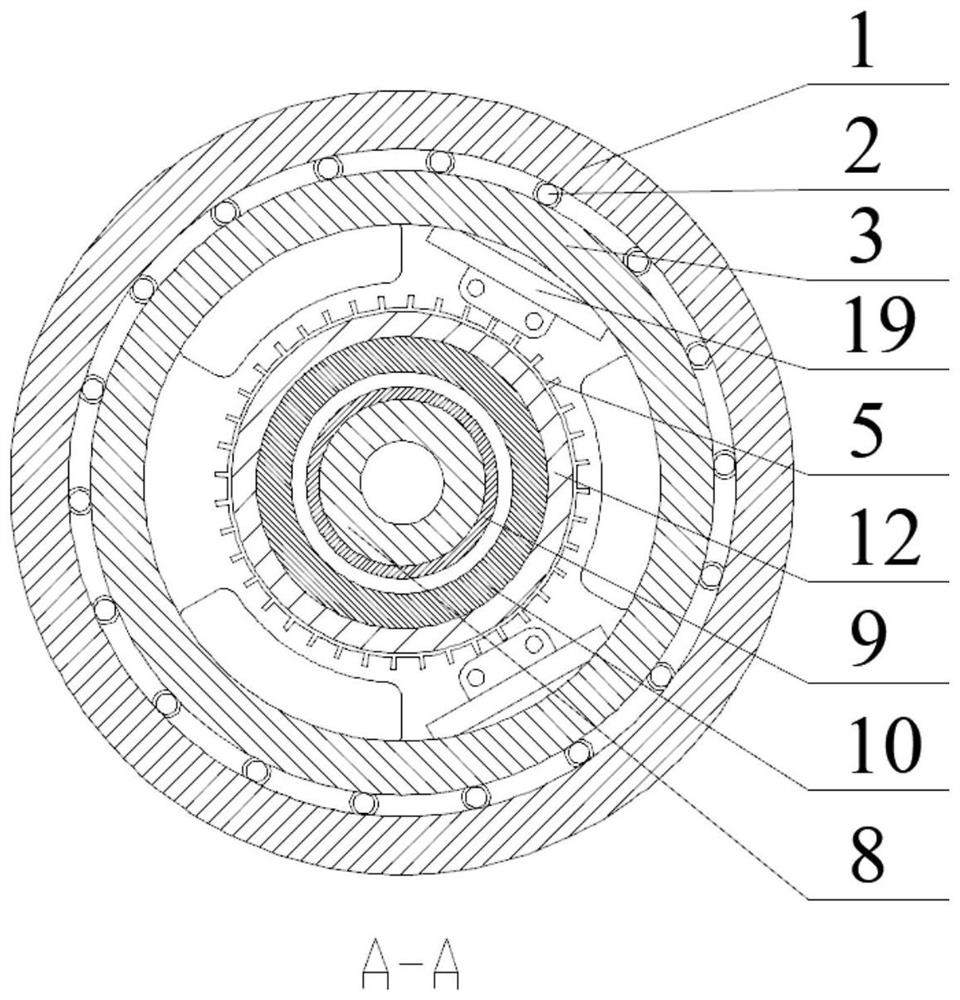

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] The purpose of the present invention is to overcome the shortcomings of the existing structure and provide an integrated all-electric rotary actuating device with high power-to-weight ratio, strong bearing capacity and small installation space, which is used for the servo control of the rudder surface and the rotation of the robot arm joints etc.

[0021] refer to Figure 1 to Figure 6 , an all-electric rotary actuating device with high power-to-weight ratio integration and large load, including: outer cavity 1; threaded roller 2; inner cavity 3; fixed shell 4; stator heat sink 5; torque sensor outer ring 6. Torque sensor inner ring 7; rotor sleeve 8; permanent magnet 9; motor stator 10; non-contact temperature sensor 11; stator sleeve 12; outer ring gear 13; sun gear 14; angle sensor inner ring 15; angle sensor Outer ring 16; planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com