Fan blade of industrial electric fan

A technology for industrial electricity and fans, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump components, etc. It can solve problems that affect performance, large air gaps, and increased frequencies. Achieve the effect of improving the wind blowing effect, large air supply area, and increasing the wind blowing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

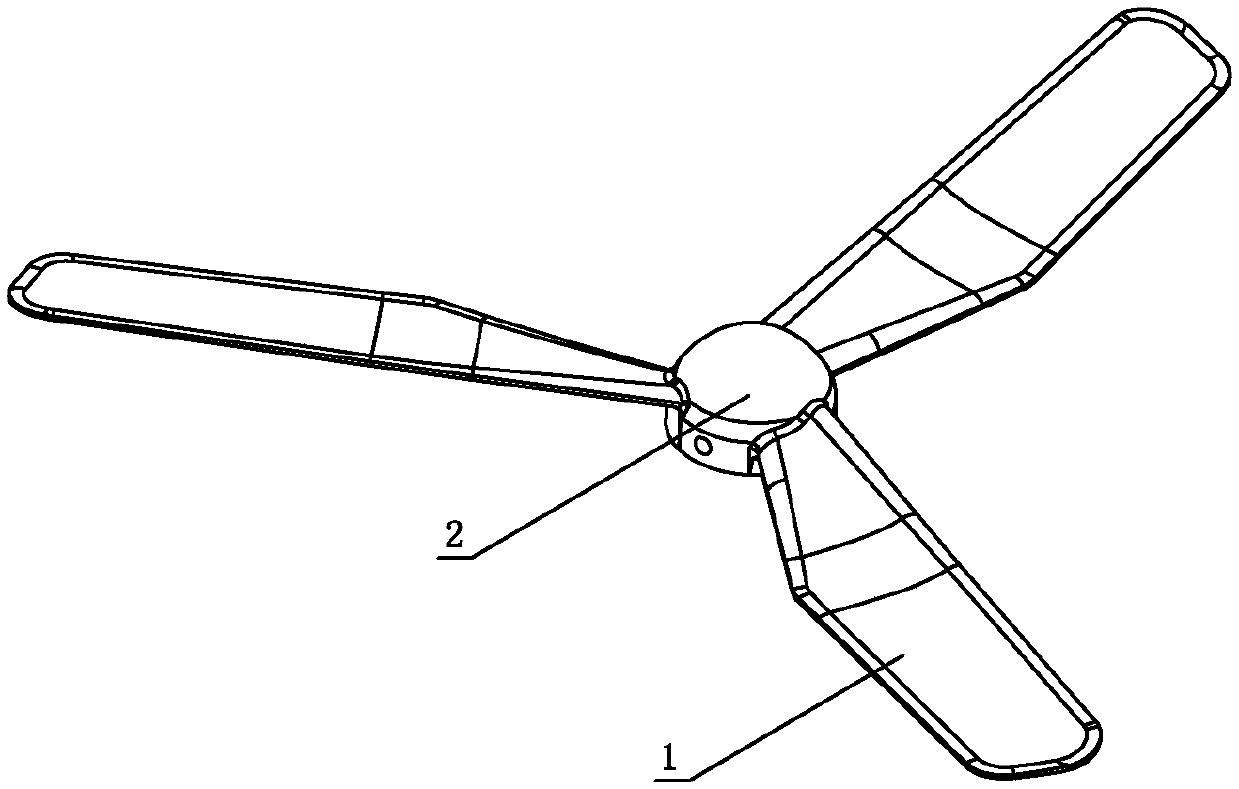

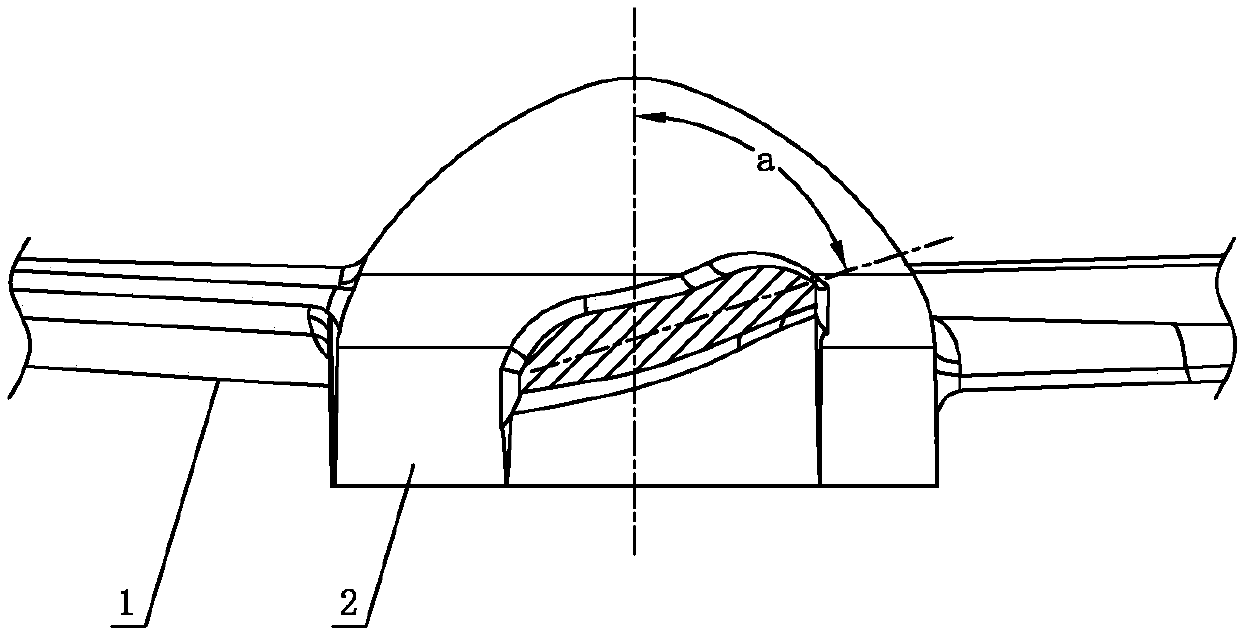

[0032] see Figure 1-Figure 8 , the blade diameter of the industrial electric fan involved in this embodiment is 750 ± 5% mm, the blade includes a blade 1 and a hub 2, the root of the blade 1 is connected to the hub 2, and the blade 1 extends radially from the root; the blade 1 is provided with three pieces, and each blade 1 is rotationally symmetrical and uniformly distributed in a ring; the root of the blade 1 is arranged obliquely relative to the rotation axis of the hub 2, and the angle a between each other is 72°; the blade 1 is twisted clockwise while extending radially; the blade 1 has a length of d 1 is 338±5%mm, the blade 1 is twisted clockwise so that the included angles between different positions and the rotation axis of the hub 2 are different, wherein, in the blade 1 1 / 3d 1 The angle b between the section of the position and the axis of rotation of the hub 2 is 81°, at the blade 1 2 / 3d 1 The angle c between the section of the position and the rotation axis of t...

no. 2 example

[0041] see Figure 9-Figure 15The blade diameter of the industrial electric fan involved in this embodiment is 650±5% mm, which is different from the first embodiment in that: the root of the blade 1 is inclined relative to the rotation axis of the hub 2, and the angle a between them is is 71°; blade 1 twists clockwise while extending radially; the length of blade 1 is d 1 is 283±5%mm, blade 1 is twisted clockwise so that the included angles between different positions and the rotation axis of hub 2 are different, among which, blade 1 1 / 3 d 1 The angle b between the section of the position and the rotation axis of the hub 2 is 79°, at the blade 1 2 / 3 d 1 The angle c between the section of the position and the rotation axis of the hub 2 is 80°.

[0042] The length d of the windy area 1.1 3 with the length d of the transition zone 1.2 2 The ratio between them is: 17:10.

[0043] The ratio of the length d1 of the blade 1 to the maximum width d4 of the blade 1 is 4:1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com