Drive-by-wire hydraulic brake system using liquid high pressure source generator

A hydraulic brake and generator technology, applied in the direction of brakes, brake-by-wire brakes, brake transmissions, etc., can solve the problem that the braking system cannot be applied to electric vehicles, the life of the high-voltage accumulator is limited, and the braking system is harmful. problems, to avoid frequent replacement of high-pressure accumulators, low failure probability, and eliminate life-limited effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical scheme of the present invention will be further explained and described below in combination with the accompanying drawings in the form of specific embodiments.

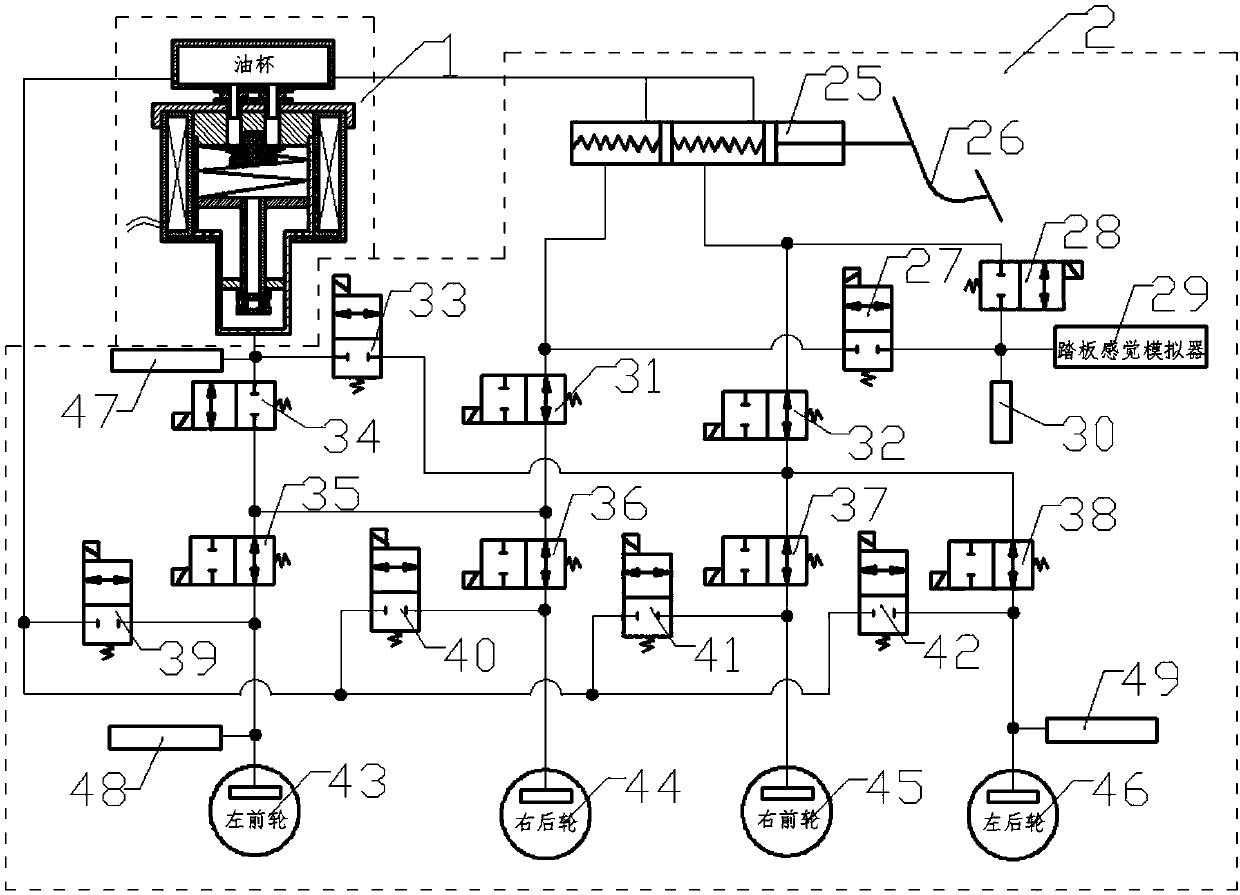

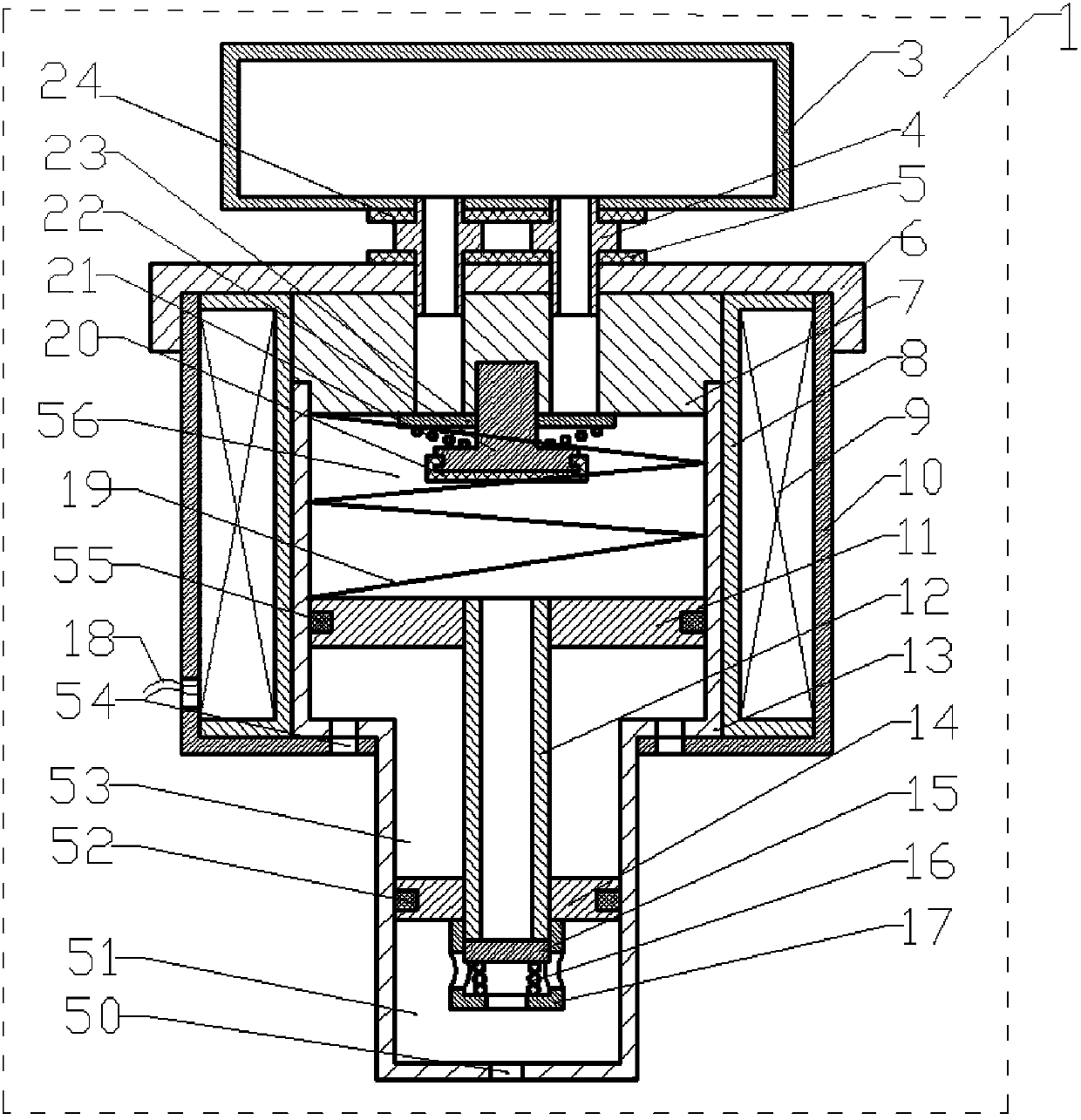

[0044] refer to figure 1 According to the present invention, the on-line hydraulic braking system of a liquid high-pressure source generator is composed of a liquid high-pressure source generator 1 and an actuator 2 of the brake-by-wire system.

[0045] The brake-by-wire system executive mechanism 2 is composed of a brake master cylinder 25, a brake pedal 26, a front cavity simulator coupled with a normally closed valve 27, a rear cavity simulator coupled with a normally closed valve 28, a pedal feeling simulator 29, a pedal pressure Sensor 30, front cavity simulator coupling normally open valve 31, rear cavity simulator coupling normally open valve 32, generator first liquid outlet valve 33, generator second liquid outlet valve 34, left front booster valve 35, right rear booster valve Pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com