Inverter direct current pulse argon arc welding machine

A technology of DC pulse and argon arc welding machine, which is applied in the direction of arc welding equipment, welding equipment, welding accessories, etc. It can solve the problems of poor heat dissipation, unreasonable, inconvenient carrying and transportation, etc., so as to achieve convenient movement, labor saving, Portable and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings.

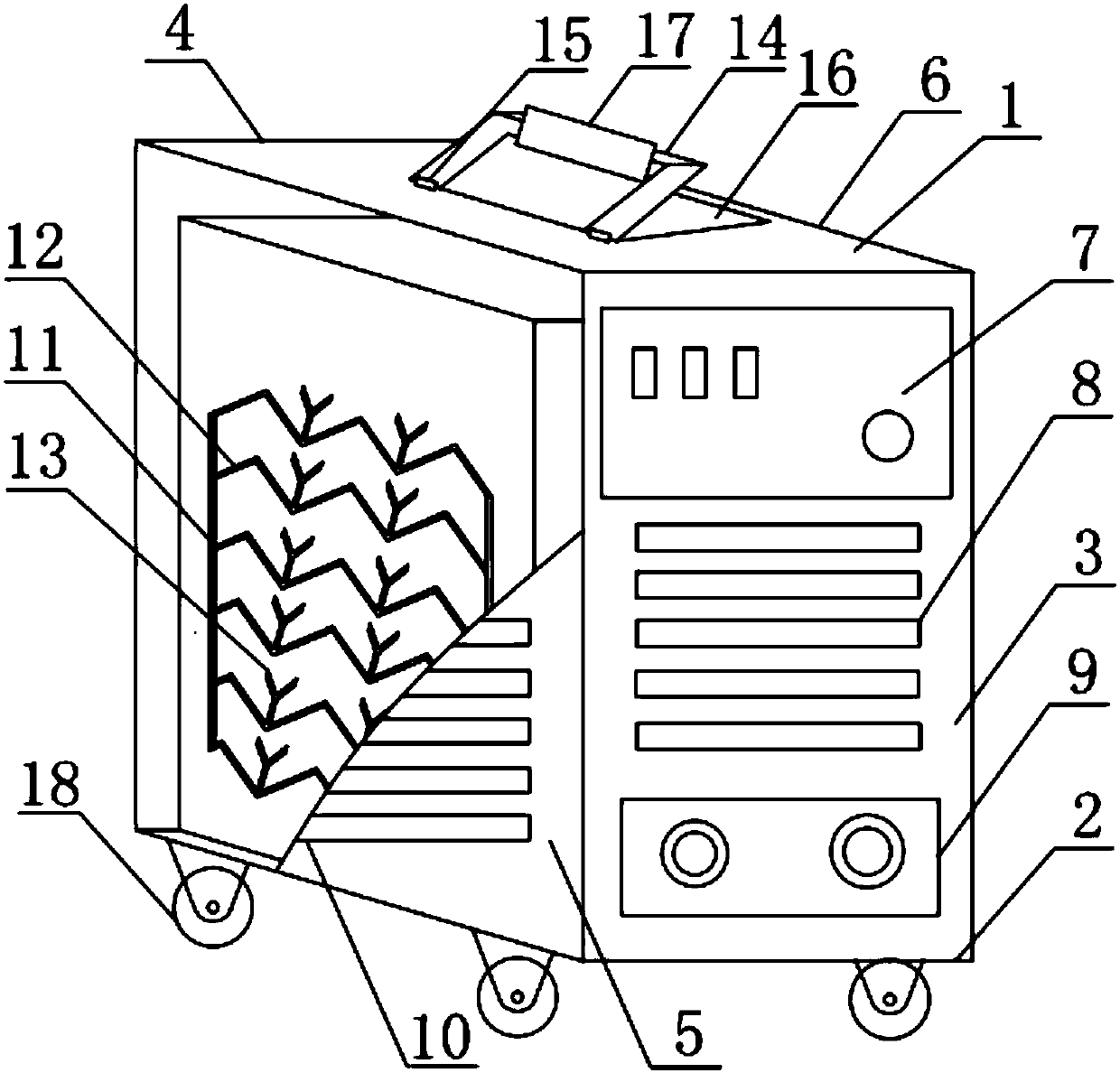

[0020] like figure 1 As shown in the figure, an inverter type DC pulse argon arc welding machine of the present invention includes a chassis and a control circuit installed in the chassis. The chassis is composed of a top panel 1, a bottom panel 2, a front panel 3, a rear panel 4, a left panel 5 and a The right panel 6 is connected, the upper part of the front panel 3 is provided with an operation panel 7, the middle part is a waterproof shutter 8, the lower part is a quick-plug output panel 9, the left panel 5 is provided with a ventilation and heat dissipation window 10, the chassis A radiator is provided at the position corresponding to the ventilation and heat dissipation window 10. The radiator includes fixed plates 11 on both sides and a heat sink 12 in the middle. A Y-shaped radiating fin 13 is provided at the corner of the top plate 1 , a handle 14 is provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com