Layer-by-layer selectable double-mode laser cleaning method and device in metal 3D printing

A 3D printing and laser cleaning technology, applied in the field of 3D printing, can solve the problems of aggravating the spheroidization effect, and achieve the effect of large cleaning range, easy control and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

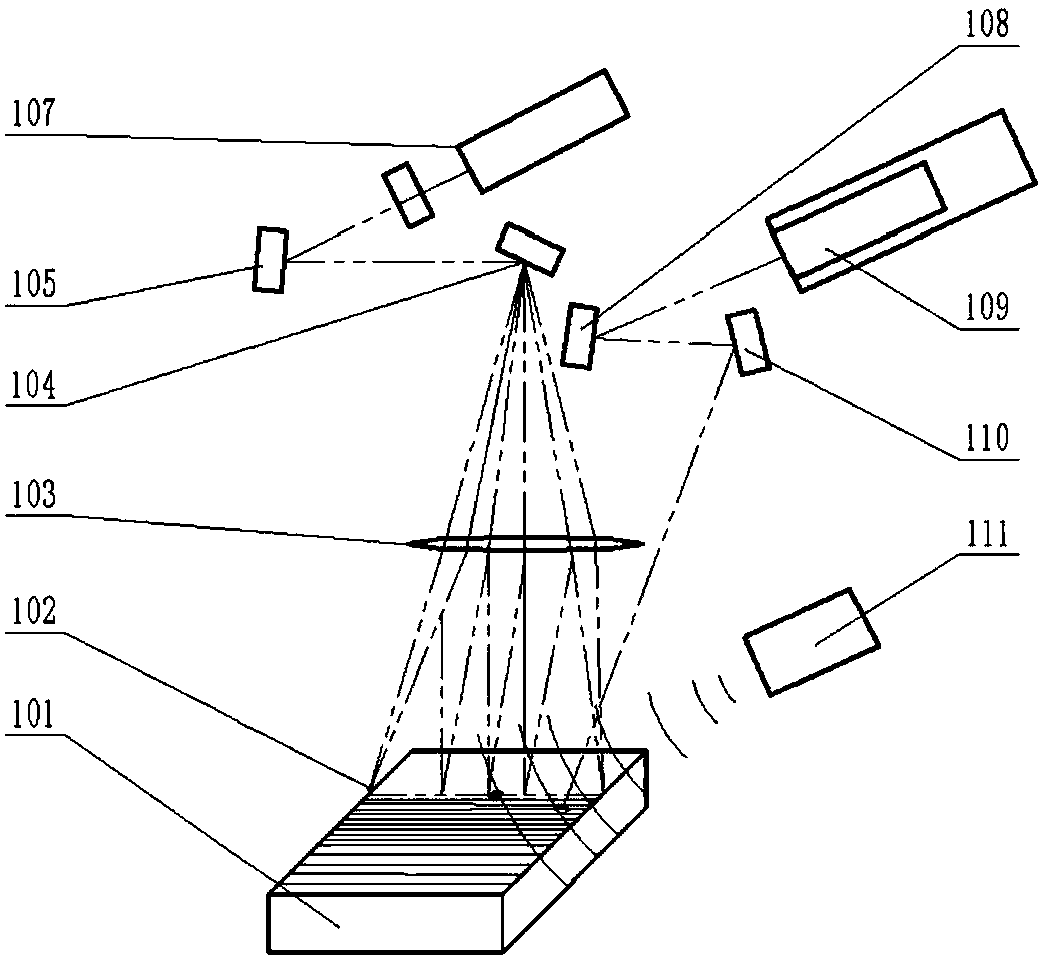

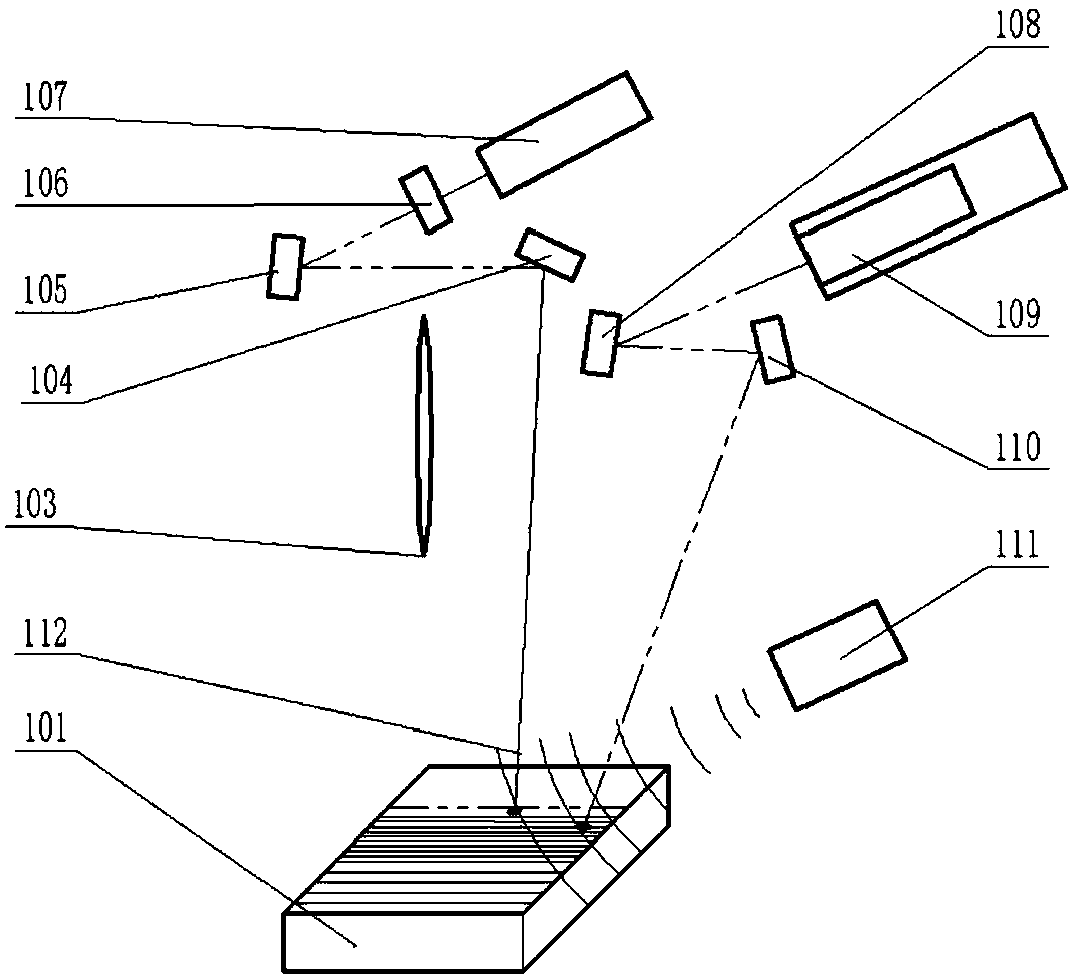

[0048] Below in conjunction with accompanying drawing and specific implementation the present invention will be described in further detail:

[0049] The layer-by-layer selective dual-mode laser cleaning method in metal 3D printing designed by the present invention includes the following steps:

[0050] s1 Set auxiliary point laser, auxiliary line laser and impurity detection device in the 3D printer;

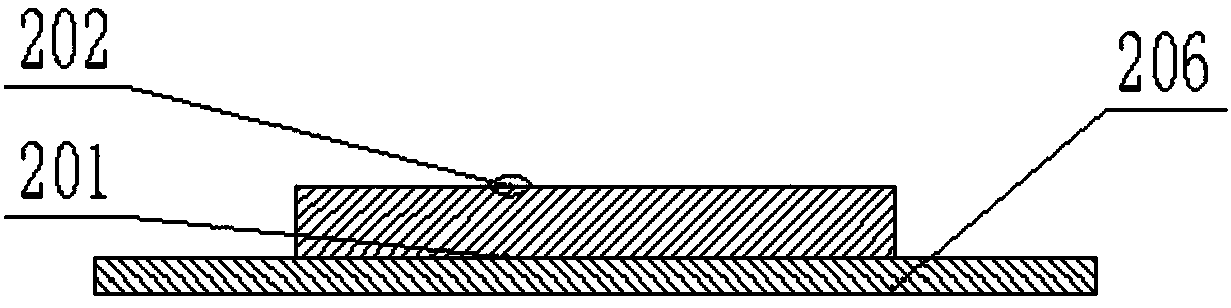

[0051] s2 Use auxiliary linear laser scanning to clean the surface of the 3D printer substrate;

[0052] s3 After the first layer of powder is laid, the 3D printing laser is used to start scanning processing. The impurity detection device detects one by one according to the printing path. When the impurity particles are larger than the specified value, the auxiliary linear laser is started to clean the printed path. When the impurity particles are smaller than the specified value When the value is set, start the auxiliary point laser to remove the impurity particles one by one. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com