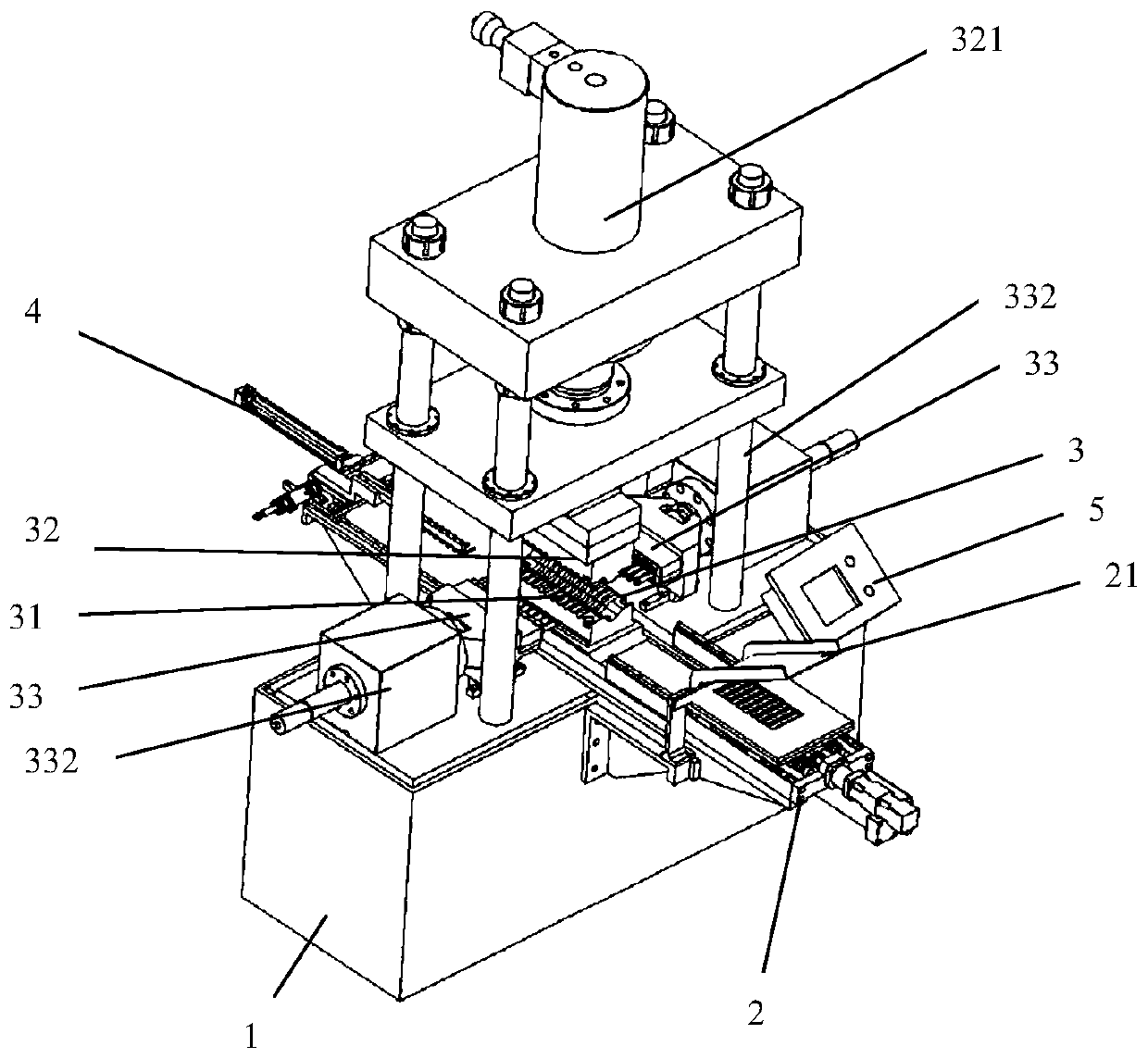

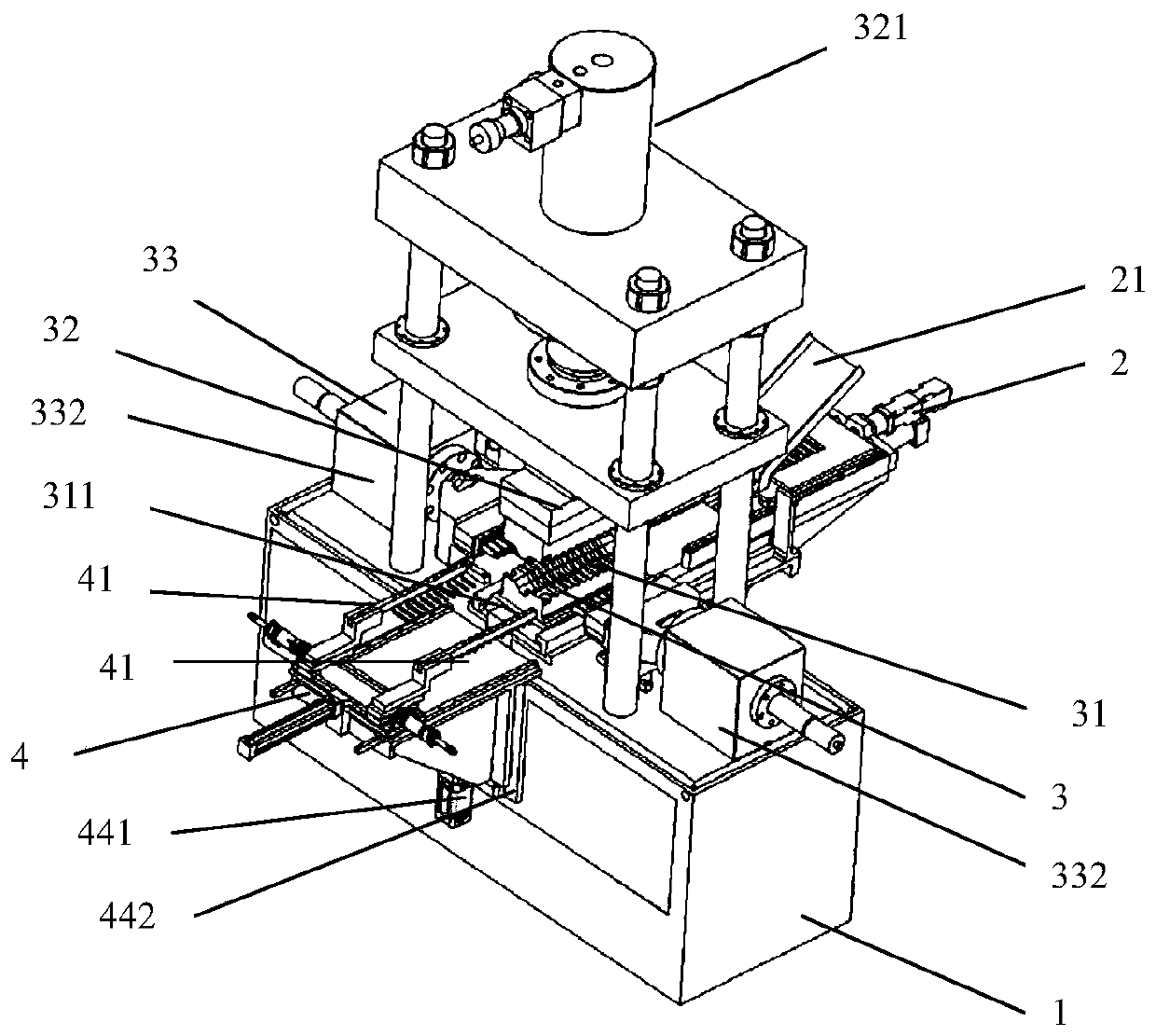

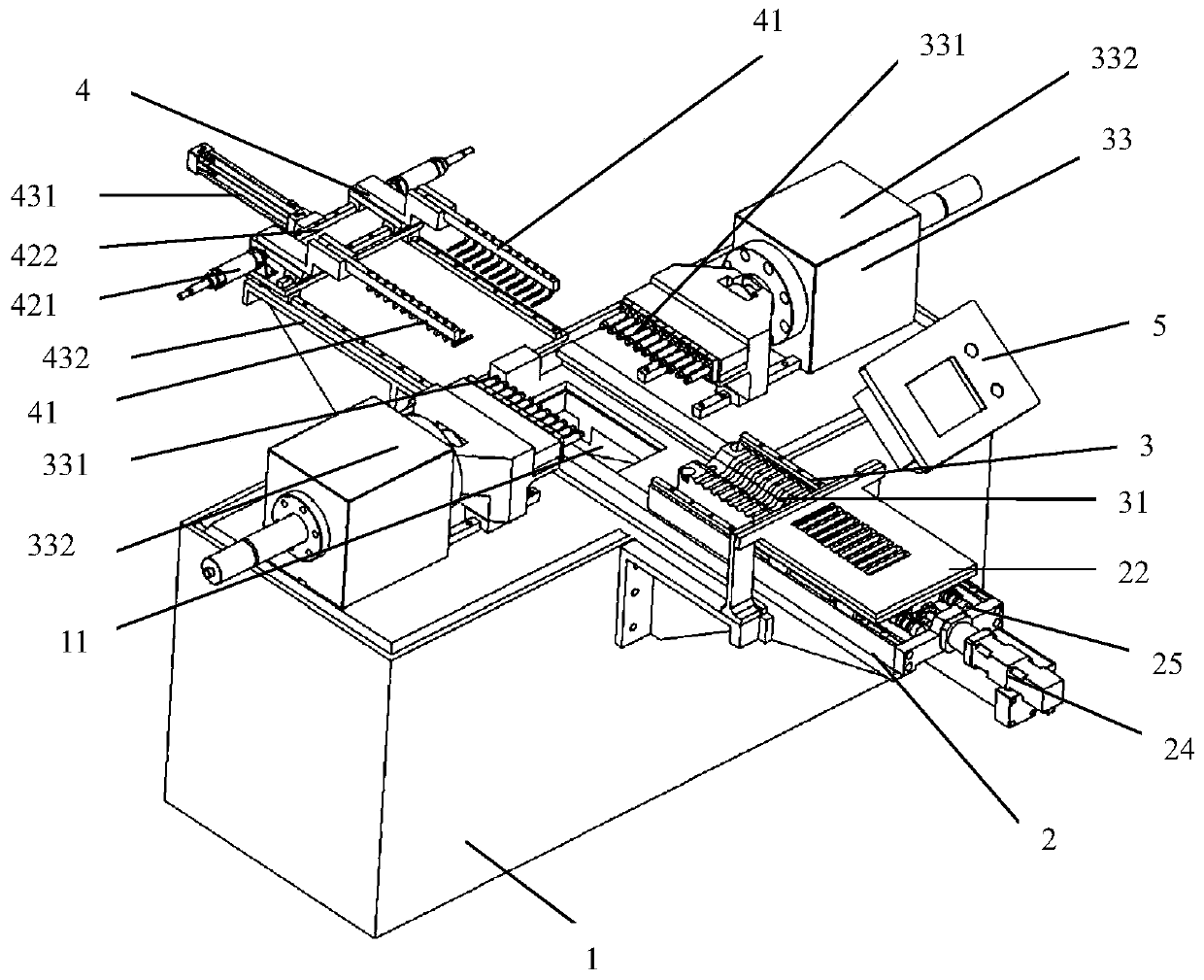

A red copper bridge bending pipe forming integrated machine

An all-in-one machine and forming mechanism technology, applied in the directions of feeding devices, manufacturing tools, positioning devices, etc., can solve the problems of poor product forming size consistency, low degree of automation, high labor intensity, etc., and achieve good product size consistency and automation. The effect of high degree and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] In a further embodiment of the present invention, it also includes the use method of the copper bridge bending pipe forming integrated machine:

[0042] Step 1: Feeding. Put a plurality of red copper straight pipe blanks on the feeding plate 21, the blanking hole 231 of the lower plate 23 is staggered with the receiving hole 221 of the upper plate 22, and the push cylinder 311 controls the lower mold base 31 to move to the bottom of the lower plate 23. The material receiving drive mechanism 24 pushes the whole material receiving plate forward sequentially, and the copper straight tube blanks in the feeding plate 21 fall into the material receiving holes 221 of the upper plate 22 one by one. After the material receiving plate finishes receiving materials, the material receiving holes 221 are aligned with the lower mold cavity 31 one by one. The blanking driving mechanism 25 controls the movement of the lower plate 23 so that the blanking hole 231 is aligned with the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com