Multidirectional linking amplitude-changing reinforced bar forming machine

A technology of forming machine and steel bar, applied in the field of steel bar bending machine, can solve the problems of complex structure of steel bar forming machine, increasing design difficulty, unfavorable equipment maintenance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

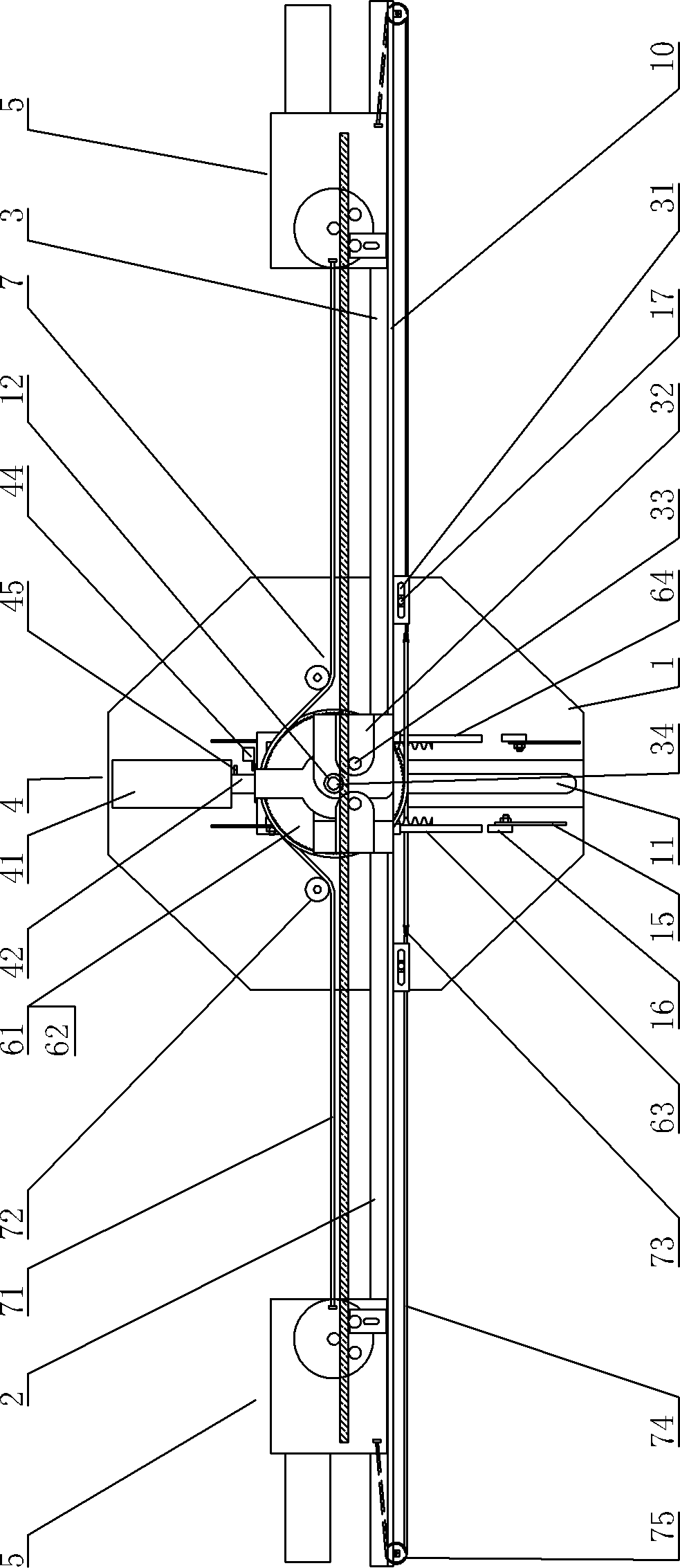

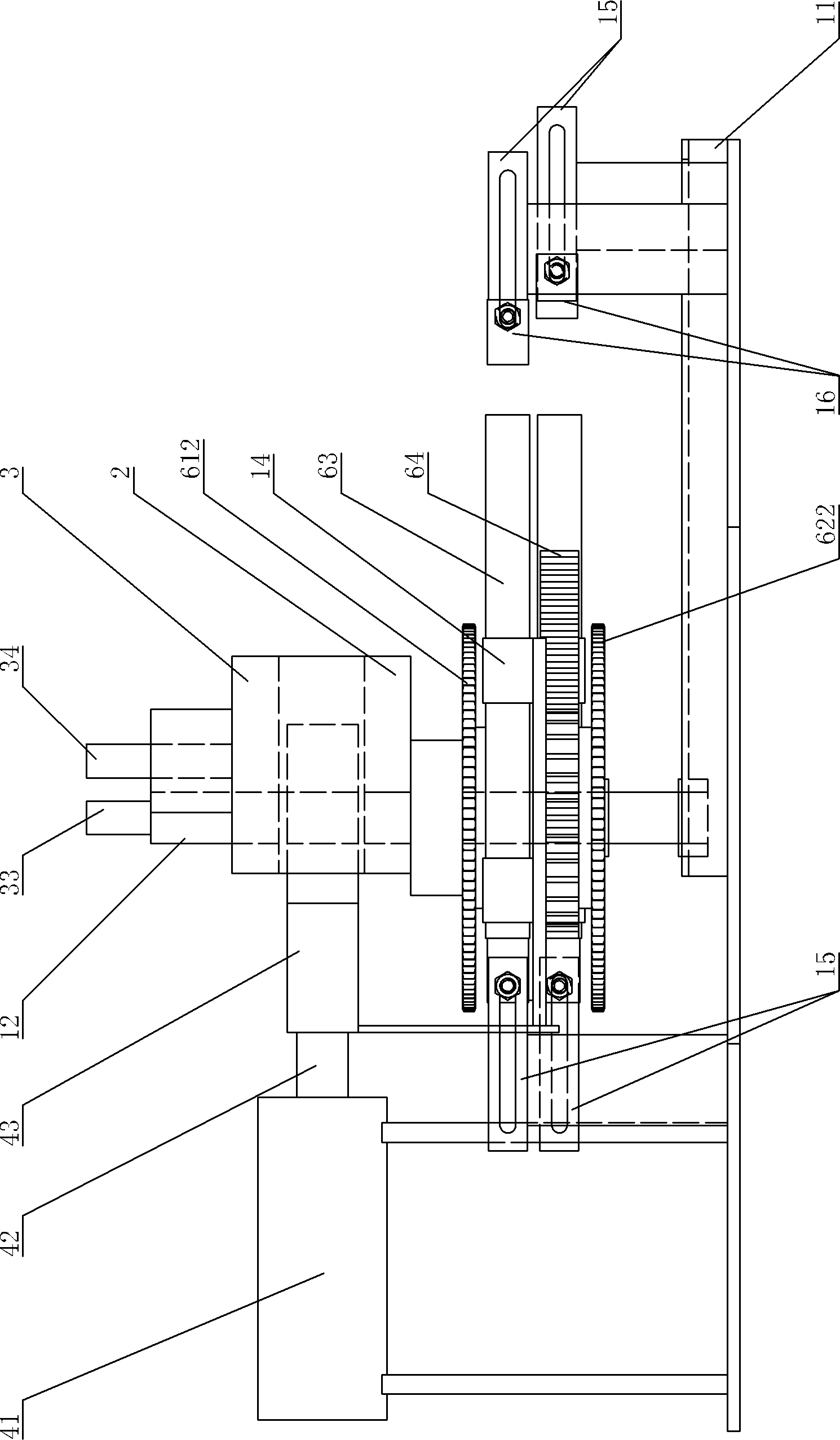

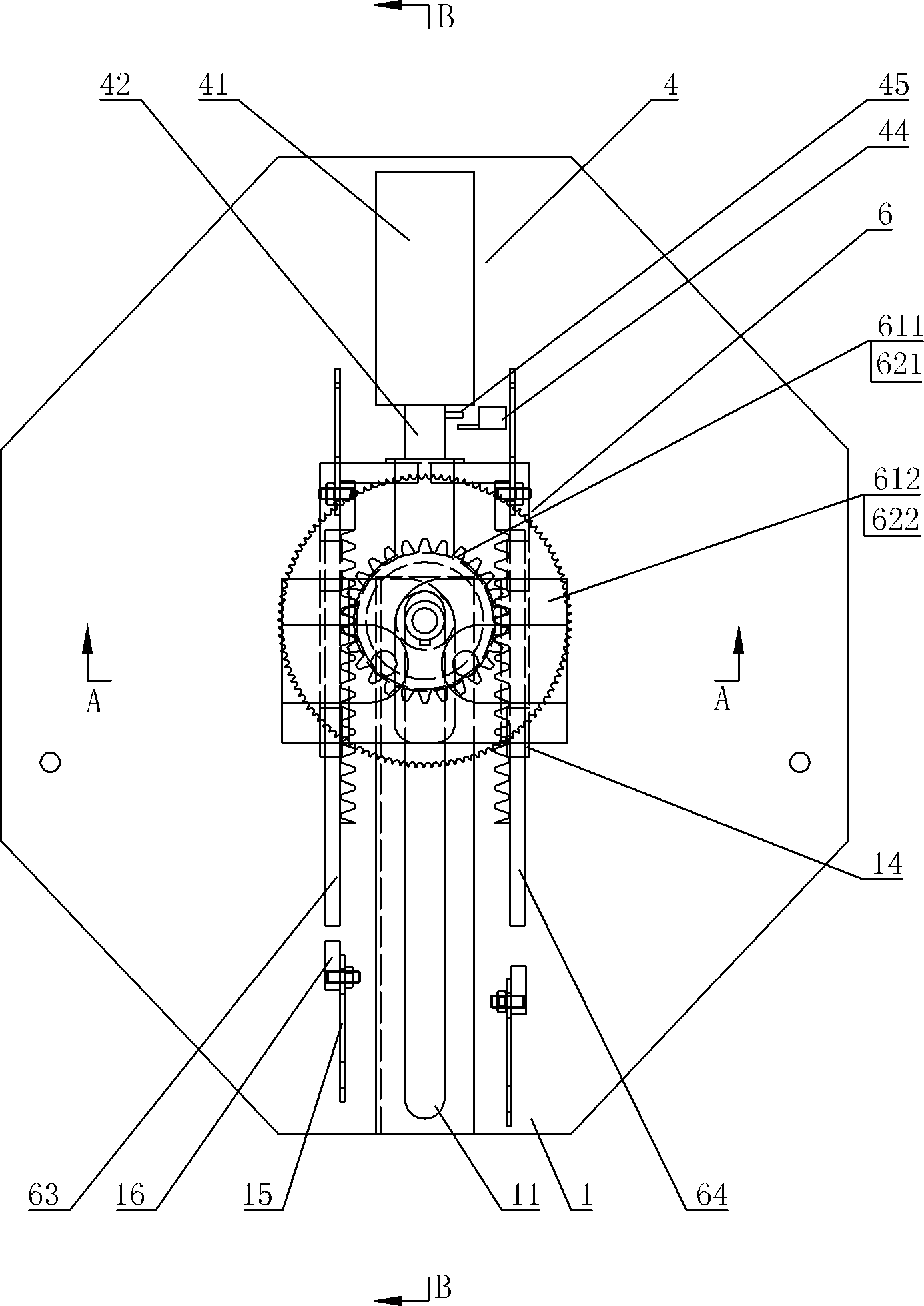

[0034] like Figure 1-Figure 6 As shown, a multi-directional linkage luffing steel bar forming machine includes a frame 1 provided with a horizontal guide groove 11, and a main shaft 12 is installed in the guide groove 11, and can slide back and forth in the guide groove 11. The left and right swing arms 2, 3 are staggered up and down and hinged on the main shaft 12, and the two swing arms have the same shape and structure, and are symmetrically arranged on both sides with the main shaft 12 as the midpoint. A push block 43 is also fixed on the main shaft 12 , and the push block 43 is sleeved on the main shaft 12 in the staggered position of the two swing arms. The driving device 4 mainly includes a power cylinder 41 fixed on the frame 1, the piston rod 42 of which is tightly connected with the push block 43, and is integrally linked. Therefore, the telescopic movement of the piston rod 42 can drive the main shaft 12 to slide and translate back and forth on the guide groove 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com