Arm type automatic reinforcing steel bar molding machine

An automatic forming machine and automatic forming technology, applied in the field of steel bar bending machines, can solve the problems of bending and forming of steel bars that cannot be straight, increase the work steps of operators, and cumbersome adjustment of related mechanism parts, so as to reduce labor intensity and increase the strength of steel bars. Specifications and standards, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

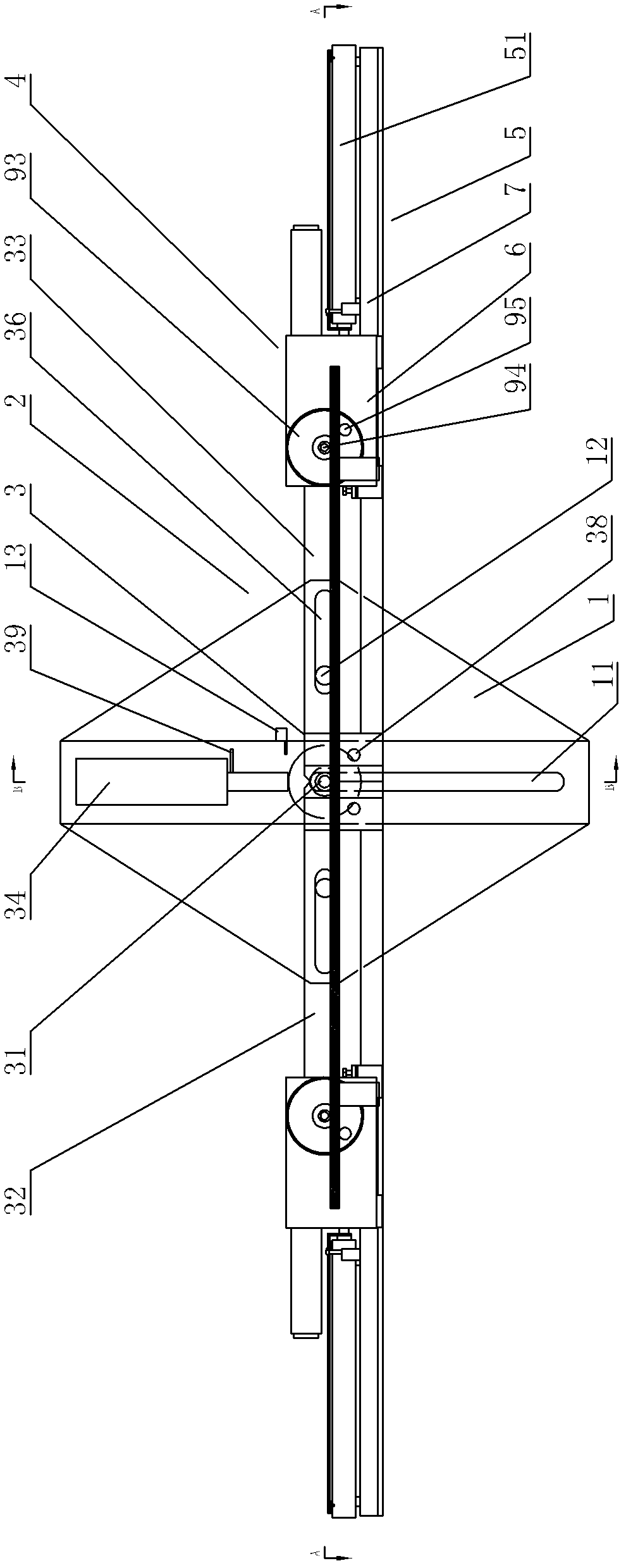

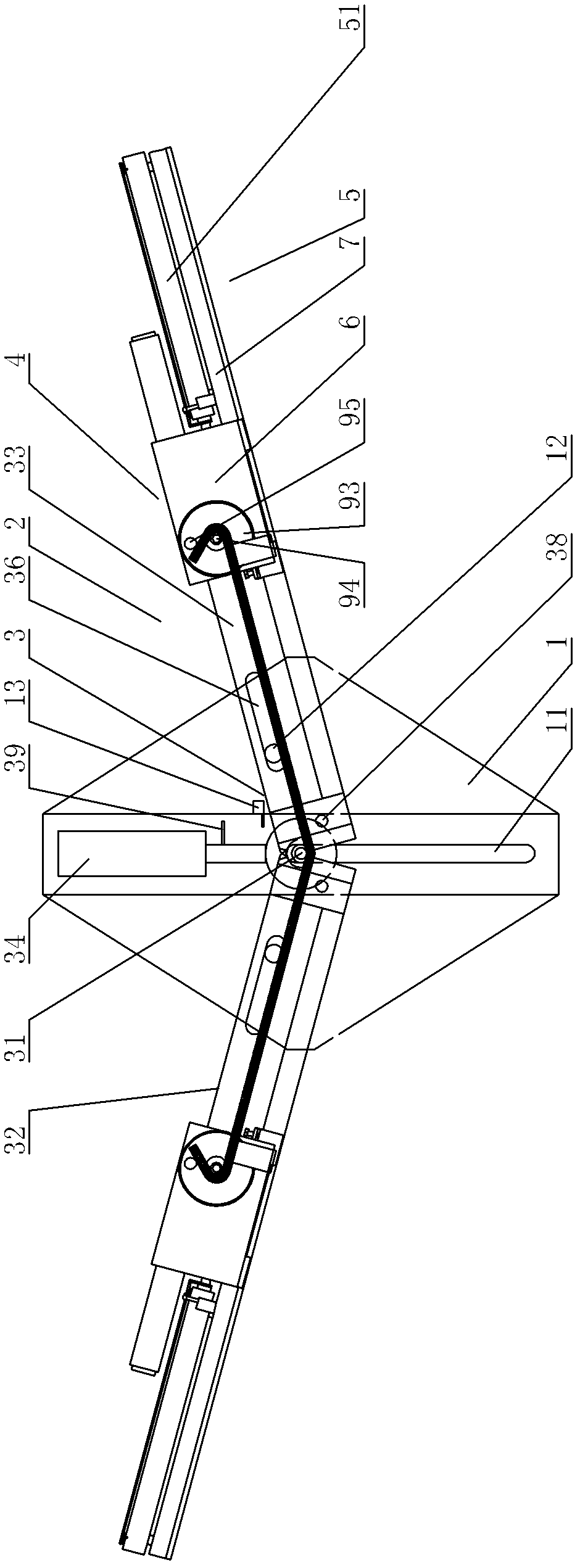

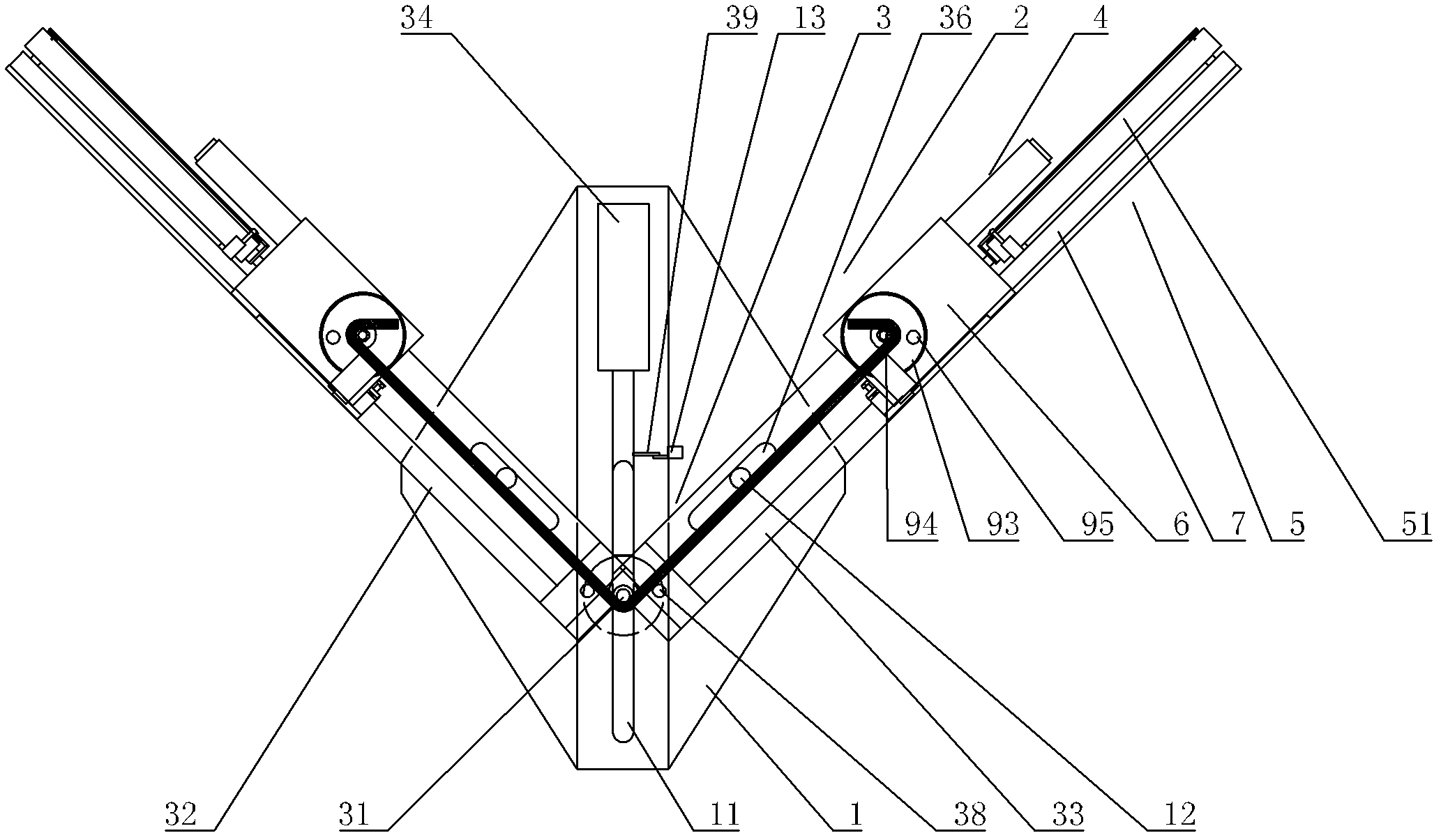

[0030] Such as figure 1 As shown, an arm-type steel bar automatic forming machine includes a bracket 1 provided with a horizontal guide groove 11, an automatic forming device 2 is provided on the bracket 1, and the automatic forming device 2 includes an articulated bending mechanism 3 arranged on the bracket 1 And the mobile bending mechanism 4 that is positioned at support 1 both sides.

[0031] Articulated bending mechanism 3 comprises left and right swing arm 32,33 and power unit 34, and the right end of left swing arm 32 and the left end of right swing arm 33 are staggered up and down symmetrically hinged on hinge shaft 31, and keep two swing arms , and the lower end faces are respectively on the same plane, so as to maintain the symmetry of the whole mechanism. The push block 35 that is fixed on the hinge shaft 31 is housed in the staggered position of two swing arms. The power unit 34 in this embodiment is a hydraulic oil cylinder fixed on the support 1. In the initial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com