High-stability and high-precision air compressor testing system

A test system, high-stability technology, used in pump testing, mechanical equipment, machines/engines, etc., can solve the problems that the test results cannot be automatically saved, the test data cannot be monitored in real time, and the assembly of the test bench is complicated. Reliable safety protection, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

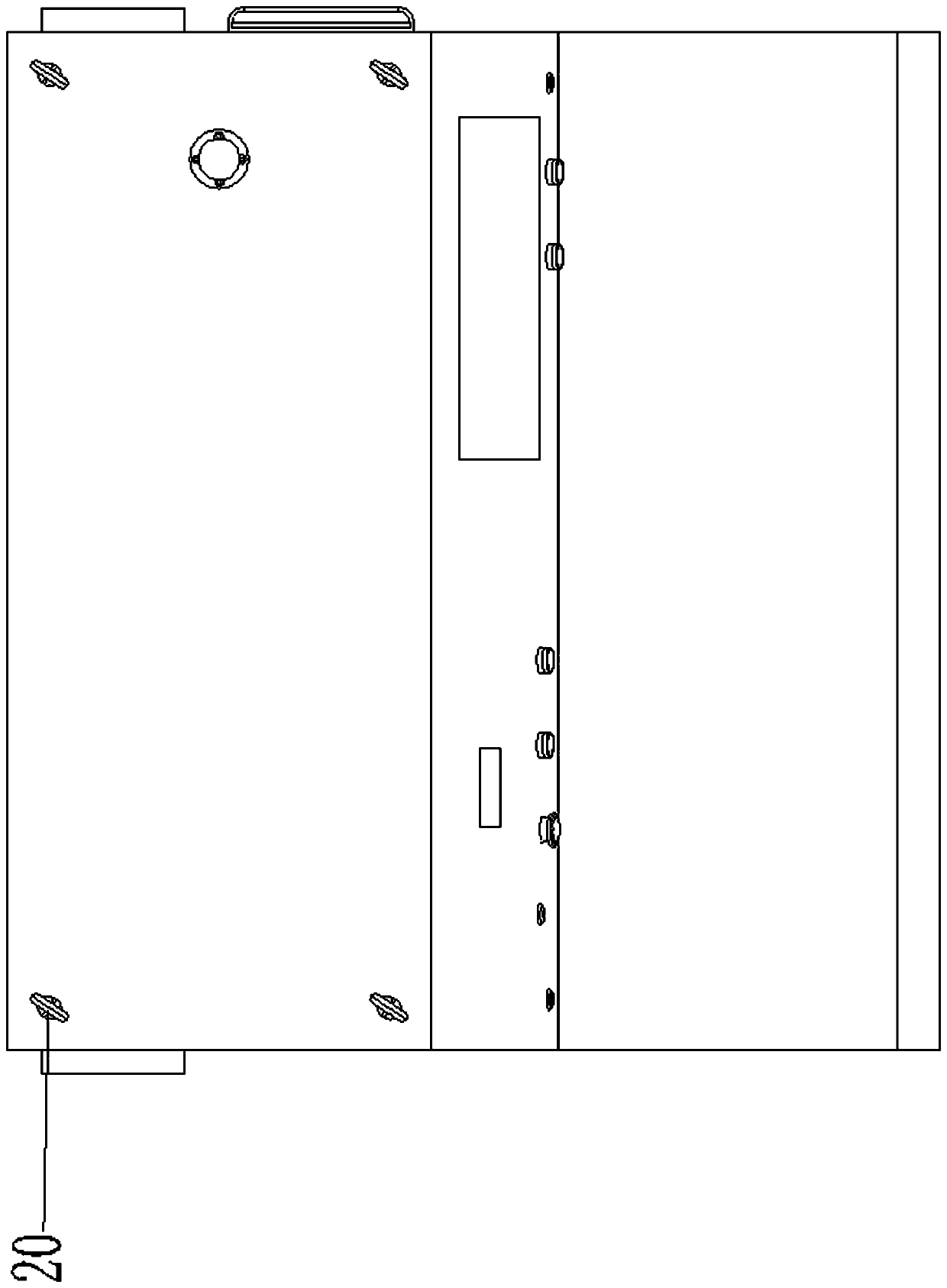

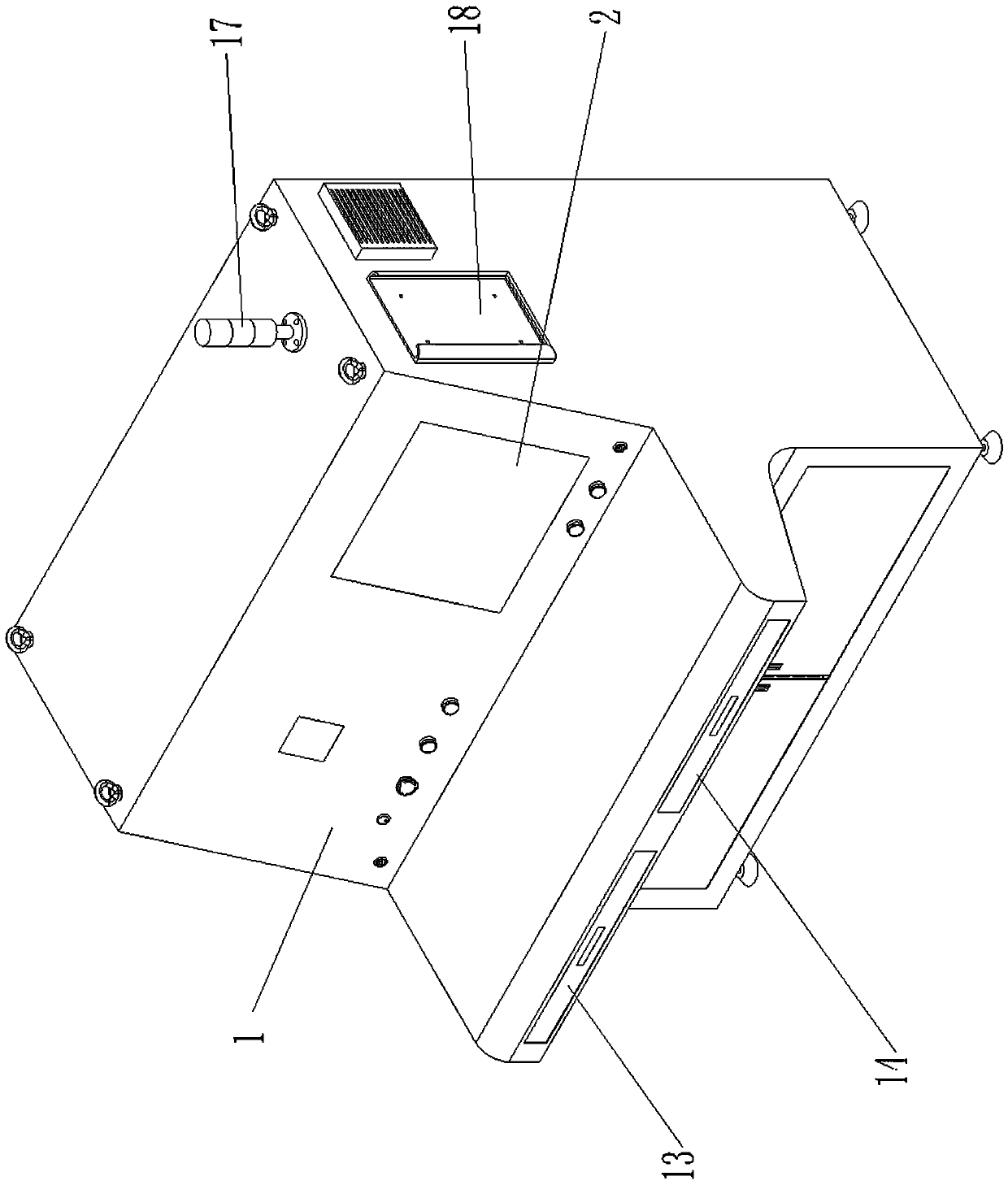

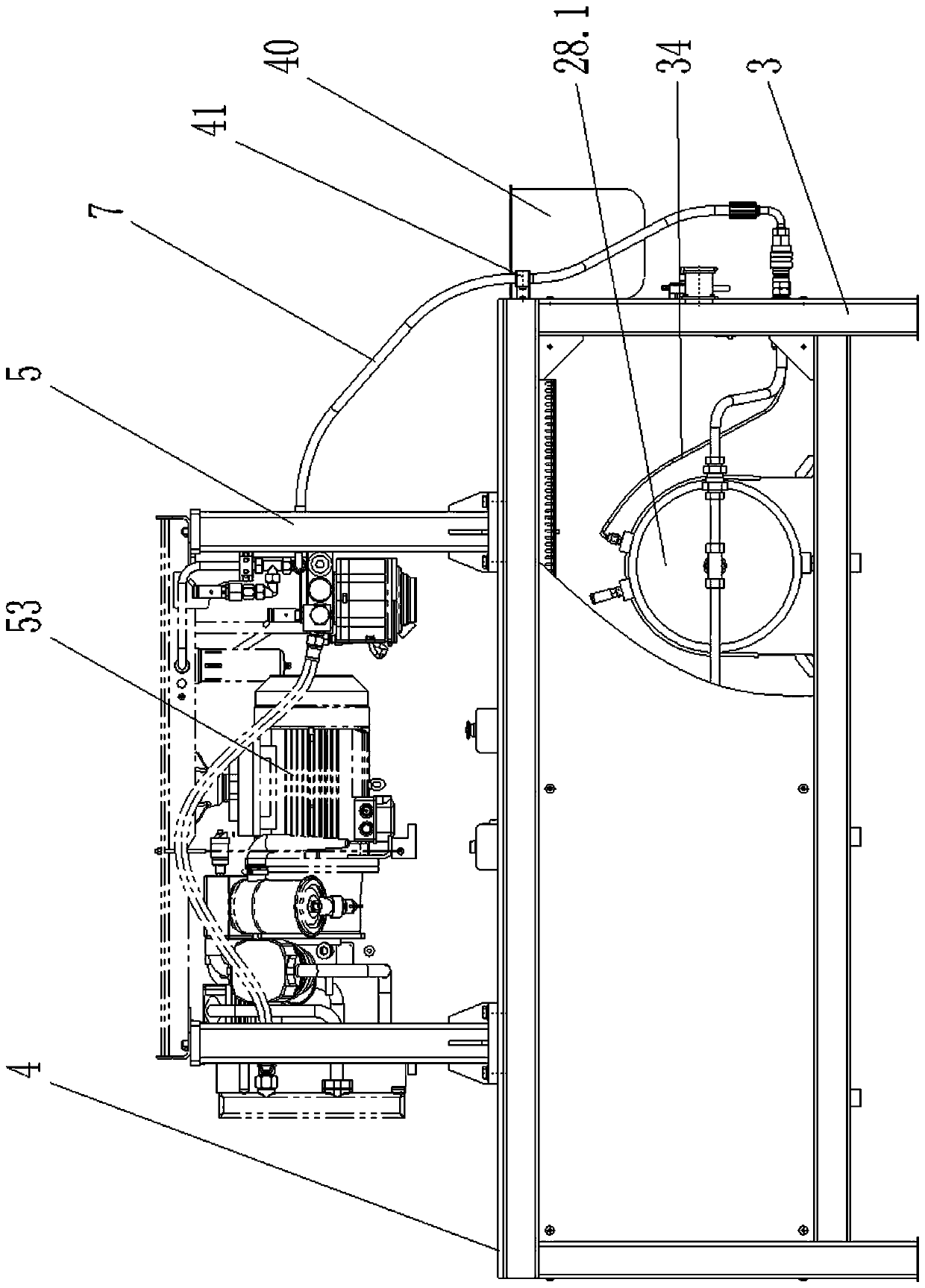

[0029] Embodiment: A high-stability and high-precision air compressor test system in this example includes a main test platform and an auxiliary test platform, such as figure 1 , figure 2 , image 3 , Figure 4 , the test main platform includes an organic cabinet 1, which is equipped with a display 2, and the inside of the cabinet is equipped with a PLC and an industrial computer. The industrial computer is connected to the display and the button group through a line. 1 External working condition machine button 9, main station emergency stop button 10, silencer button 11, start button 12, the middle part of the cabinet protrudes outward and is provided with a data drawer 13 and a keyboard and mouse drawer 14, and a power light is provided on the front of the cabinet 15. A three-phase power supply light 16, an alarm light 17 is provided on the top of the cabinet, and a data rack 18 and a radiator 19 are respectively provided on both sides of the cabinet. A suspension ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com