Methods for treating fully mechanized coal mining face roof accidents through flexible air bags

A technology of fully mechanized mining face and flexible air bag, which is applied in mining equipment, earth-moving drilling, mining equipment and other directions, can solve the problems of many processes, long time and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

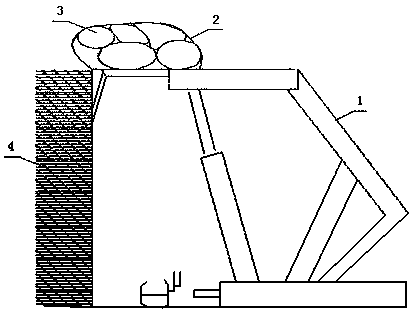

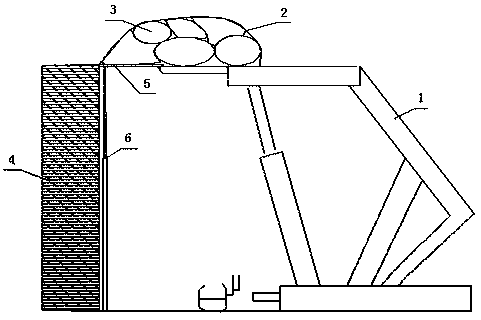

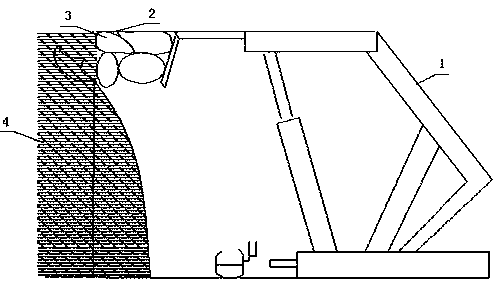

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0042] see figure 1 , in the roof caving area of the fully mechanized mining face, a space is formed on the top of the support, and the support cannot be connected to the roof. When the coal wall does not have a side or the distance between the sides is less than 1m, the roof cannot be effectively controlled, which may lead to the expansion of the scope of the roof fall, and it is necessary to build wooden piles When connecting to the roof, the flexible air bag can be used to inflate and pressurize it, so as to realize rapid roof connection, effectively control the roof, and prevent the aggravation of the roof fall. The specific operation steps are as follows:

[0043] (1) According to the actual range of the headspace in the roof fall area of the fully mechanized mining face, select a suitable size and quantity of flexible airbags 3 and fold them i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com