Animal manure treatment production technology for substrate or organic fertilizer raw material

A production process and technology of organic fertilizer, applied in the field of animal manure treatment production process, can solve the problems of difficult treatment of waste liquid, low efficiency of fermentation biogas, environmental pollution, etc., and achieve the effects of improving fermentation efficiency, expanding application scope and shortening fermentation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

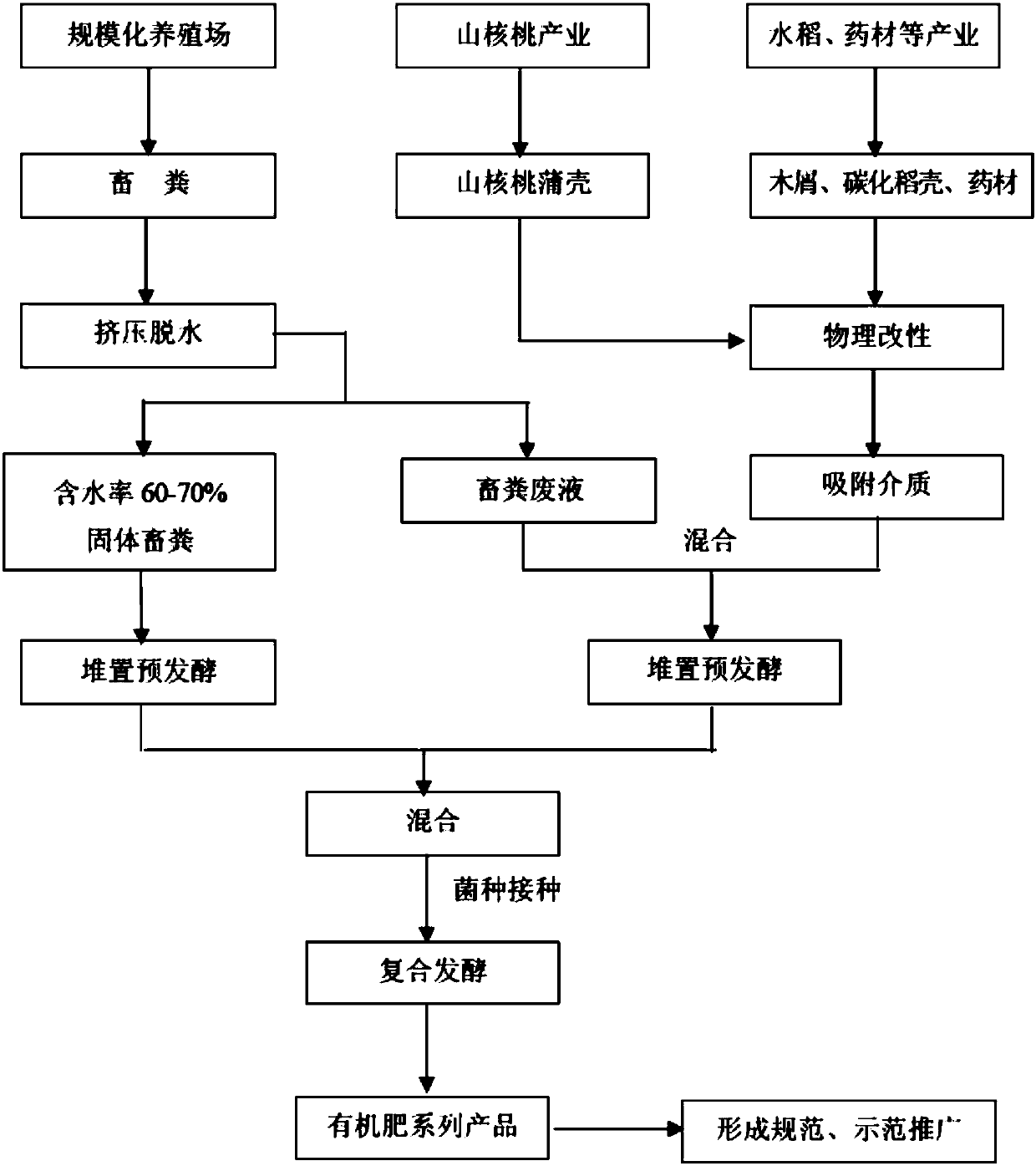

[0063] according to figure 1 Process steps shown:

[0064] (1) The fresh cow dung is dehydrated and separated by a LJF-3 solid-liquid separator, the screw speed is 45r / min, and the dehydrated solid animal manure and animal manure waste liquid with a moisture content of 55-60% are obtained.

[0065] (2) Get sawdust, dark brown hickory nut shell powder, carbonized rice husk and medicine dregs and mix according to the following mass ratio respectively:

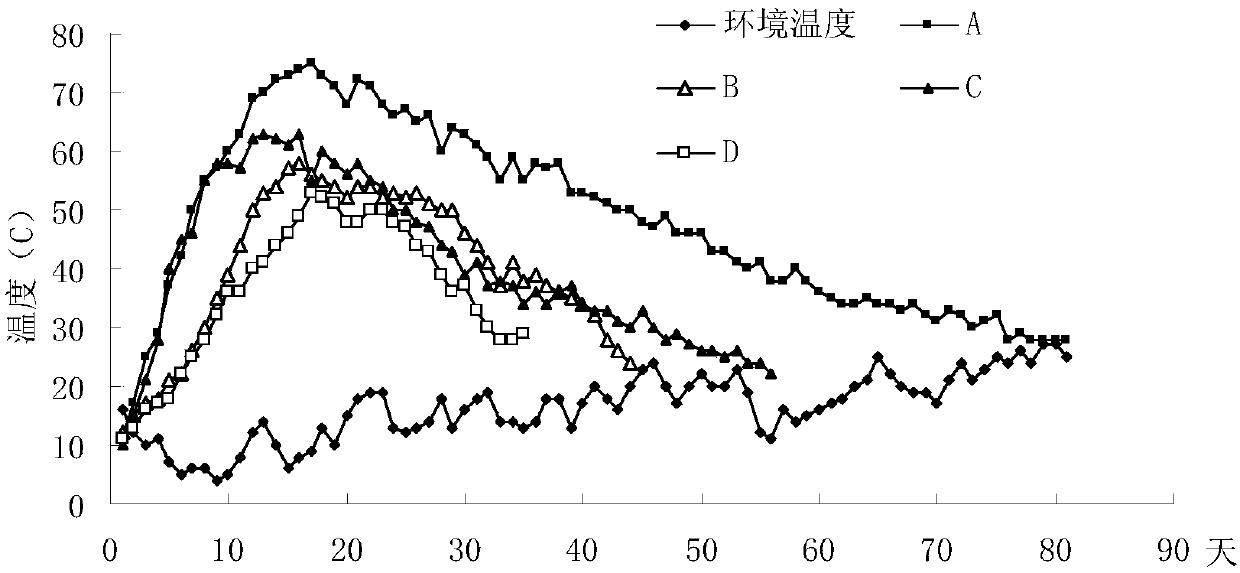

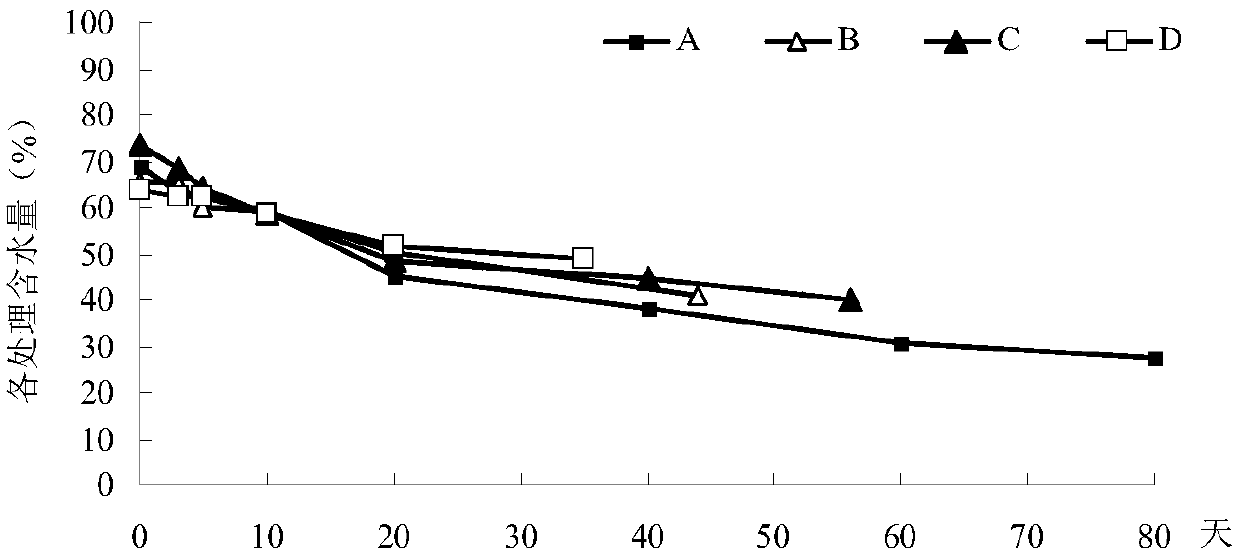

[0066] (A) 60% cow dung + 10% sawdust + 10% medicinal residue + 10% hickory nut shell + 10% carbonized rice husk

[0067] (B) 60% Cow Dung + 20% Sawdust + 10% Hickory Husk + 10% Carbonized Rice Husk

[0068] (C) 60% Cow Dung + 10% Sawdust + 20% Hickory Husk + 10% Carbonized Rice Husk

[0069] (D) 60% cow dung + 10% sawdust + 10% hickory shell + 20% carbonized rice husk.

[0070] Mixed as an adsorption medium.

[0071] (3) The adsorption medium is mixed with the waste liquid of animal manure, and the pre-fermentation is carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com