Car bumper trimming, handling and storage system

A technology of automobile bumper and storage system, which is applied in the field of automobile bumper trimming, transportation and storage system, which can solve the problems of increasing labor intensity of workers, reduce labor intensity and error rate, meet production rhythm and demand, and realize high efficiency and intelligence management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of this application.

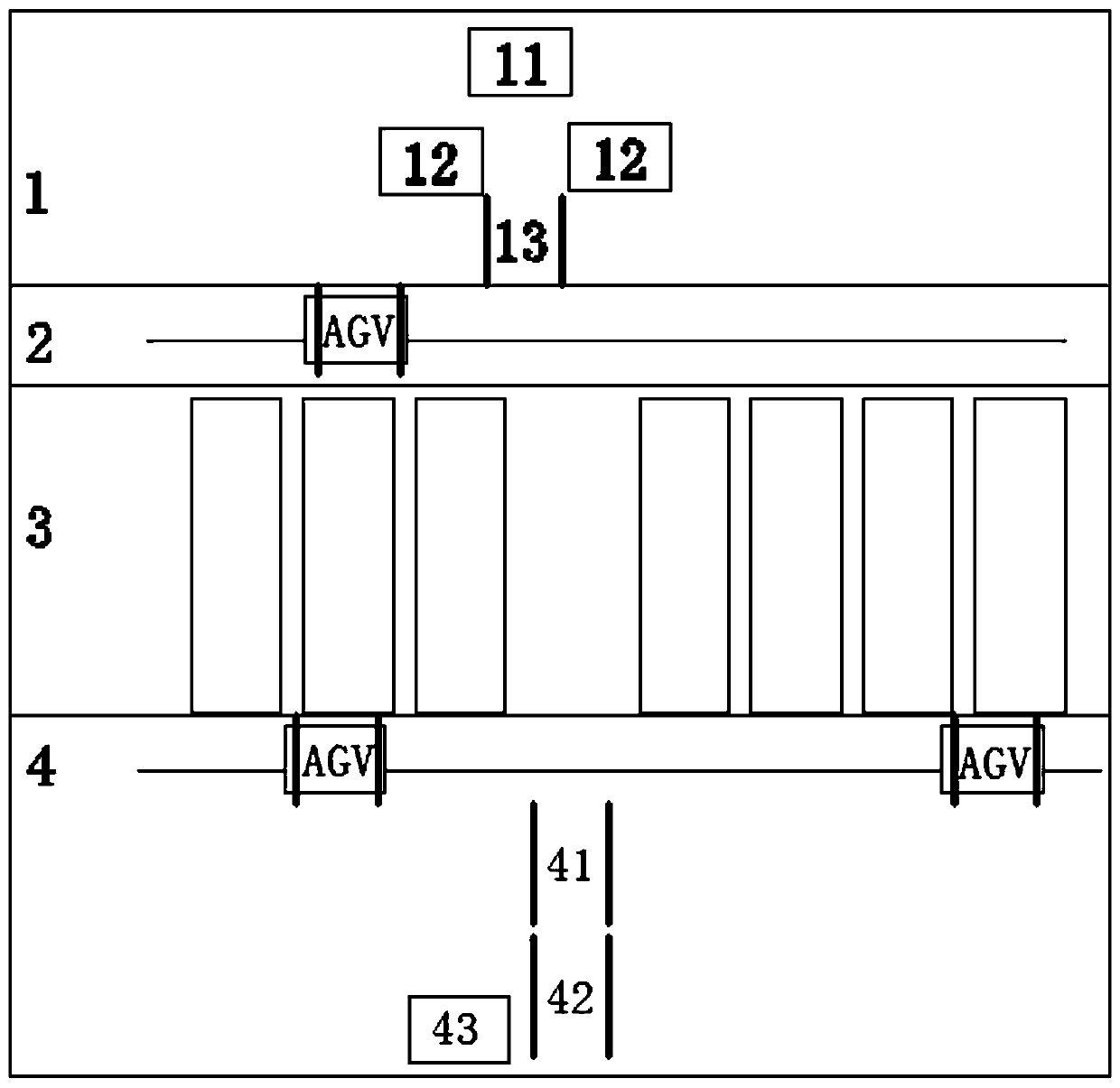

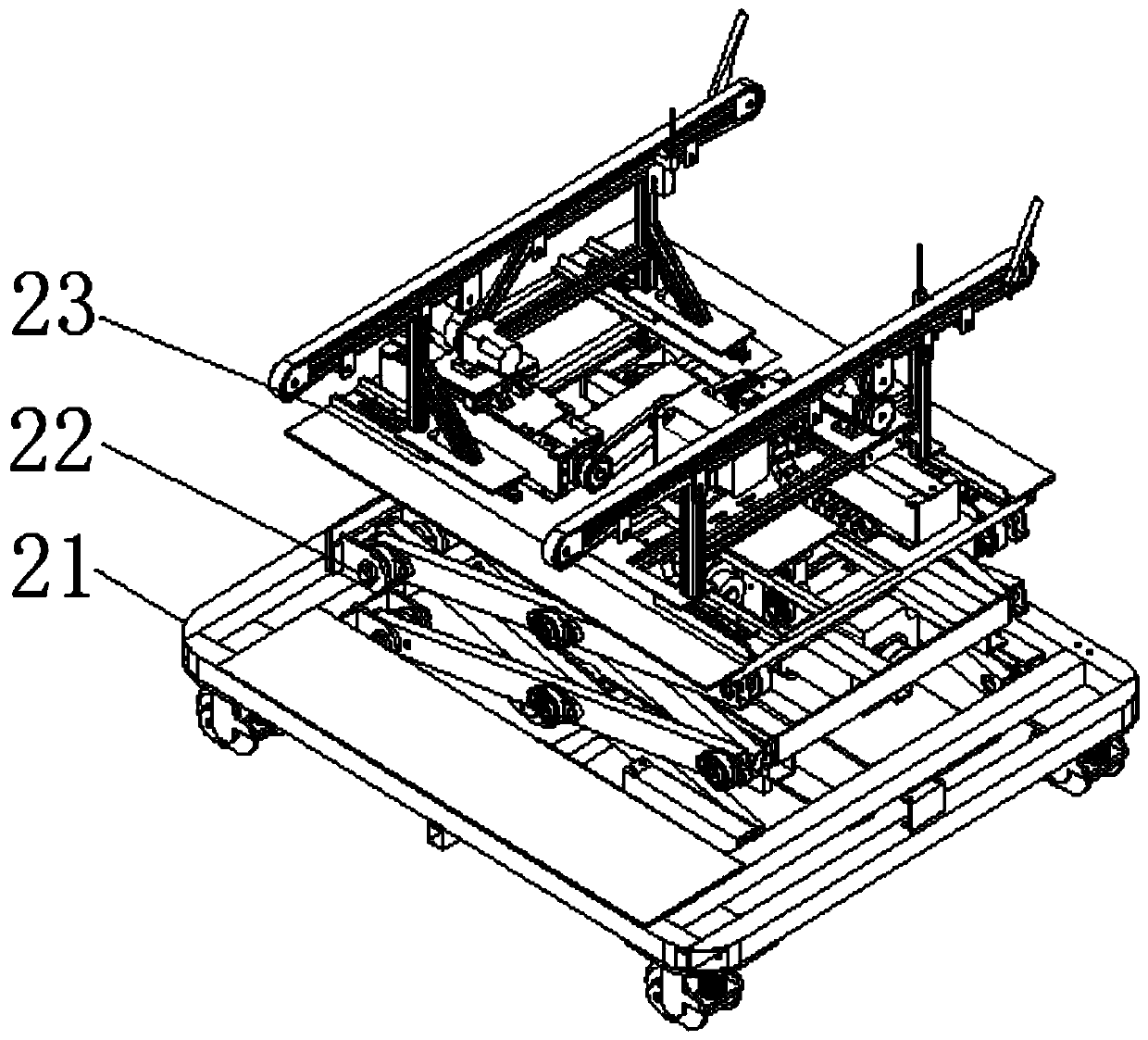

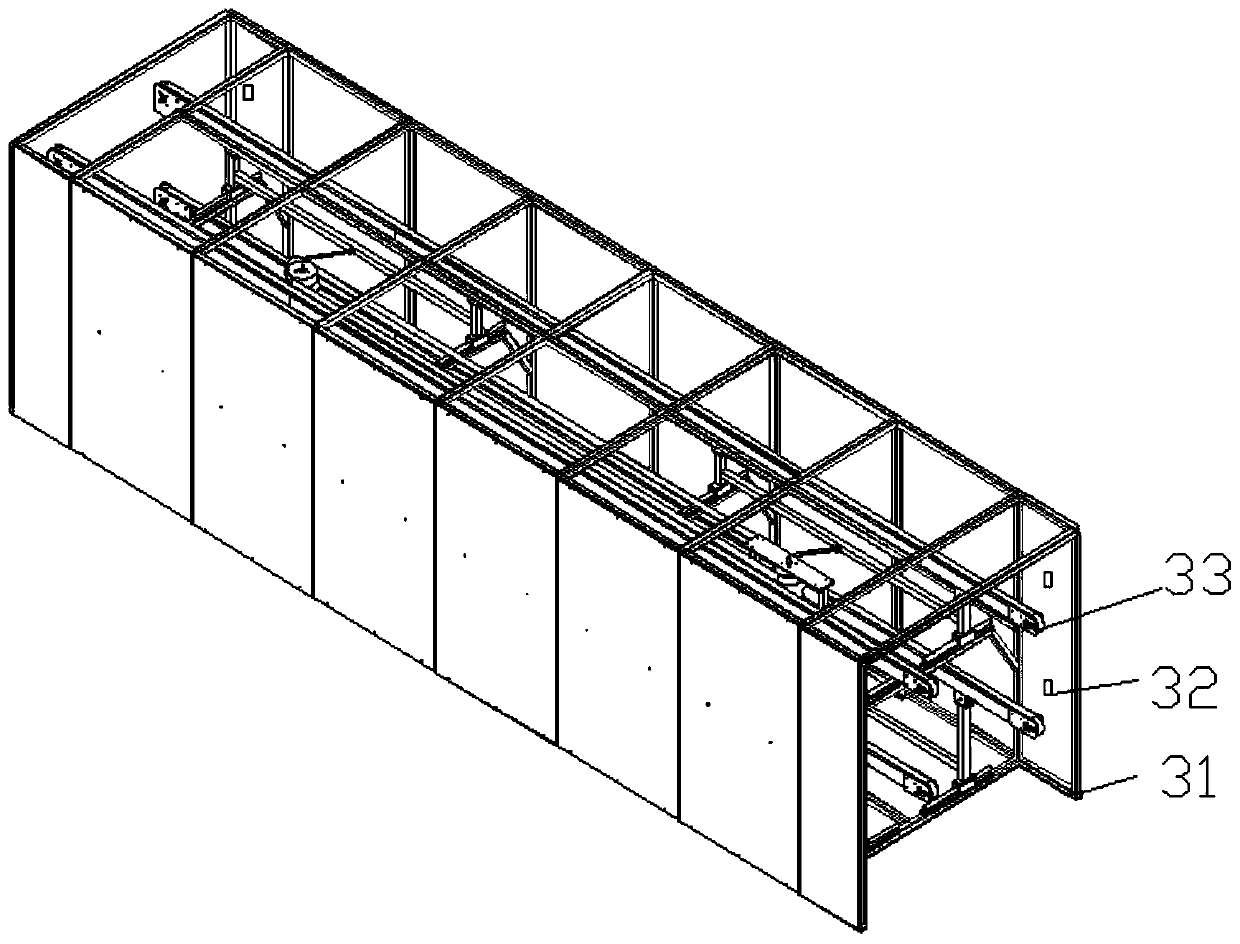

[0022] The present invention provides a car bumper trimming transportation storage system (see Figure 1-4 , Referred to as the system), which is characterized in that the system includes a finishing area 1, a conveying area 2, a storage area 3, an ingestion area 4 and a control system 5; the inlet side of the finishing area 1 is connected with the injection molding machine of the previous station, The outlet side is connected with the inlet side of the conveying area 2; the inlet side of the storage location area 3 is connected with the outlet side of the conveying area 2, and the outlet side is connected with the inlet side of the lead-in area 4; the outlet side of the lead-in area 4 is connected to the lower The inlet side connection of a pain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com