Vehicle safety belt, pyrotechnic safety belt pretensioner and flexible strip-shaped drive element

A technology of seat belt pretensioner and driving element, applied in the field of vehicle seat belts, can solve the problems of broken teeth of a driven gear, abnormal operation of the pretensioner, etc., and achieves improved meshing force, improved temperature stability, and material locking. The effect of a solid connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

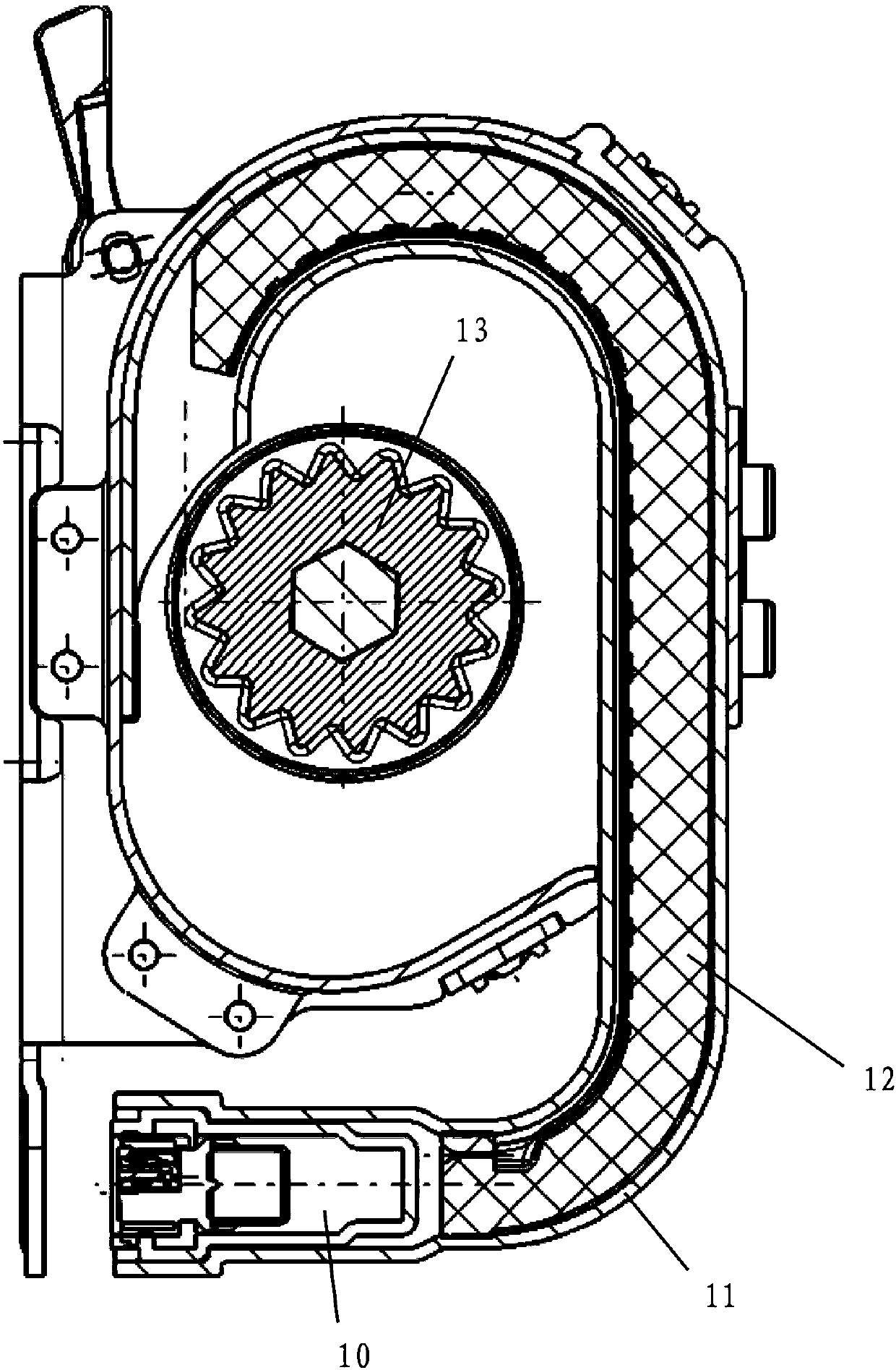

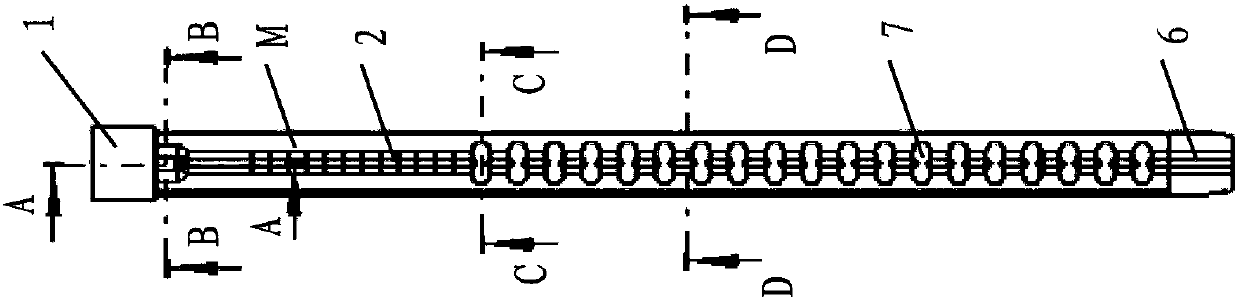

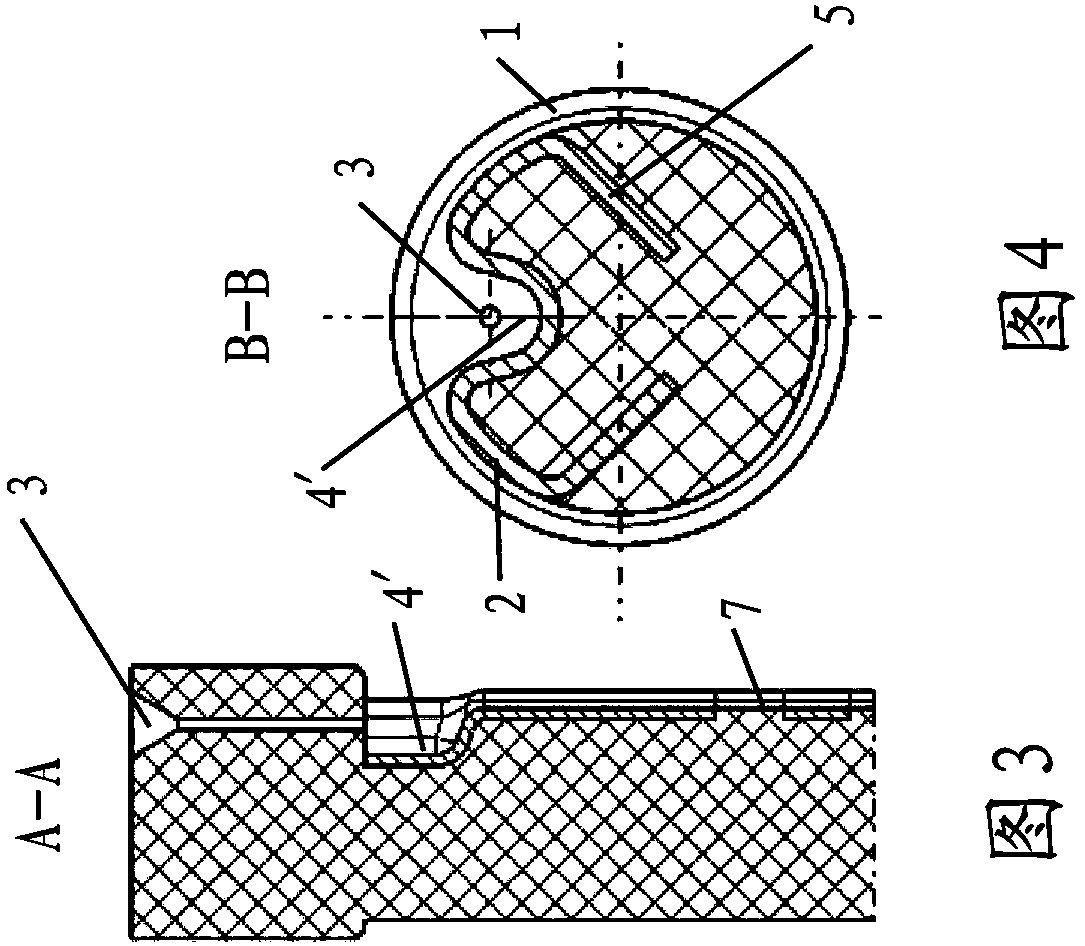

[0037] figure 1 is a schematic sectional view of a pyrotechnic seat belt pretensioner according to the invention, which comprises a pyrotechnic device 10 , a tubular housing 11 , a flexible strip-shaped drive element 12 and an output element 13 . The pyrotechnic device 10 is mounted on one end of a tubular casing 11 and is used to drive a flexible drive element 12 when triggered so that the drive element 12 moves guidedly in the tubular casing and moves through the void. Said tubular housing 11 is meandering after the stroke and engages a driven element 13 which is kinematically coupled to the belt reel. The pyrotechnic device, for example, can be triggered according to the collision signal detected by the collision sensor, so that the gunpowder contained in the pyrotechnic device is ignited and burns rapidly, and the combustion force generated thereby pushes the flexible driving element 12, so that the driving element 12 is winding in a meandering direction. It moves guidedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com