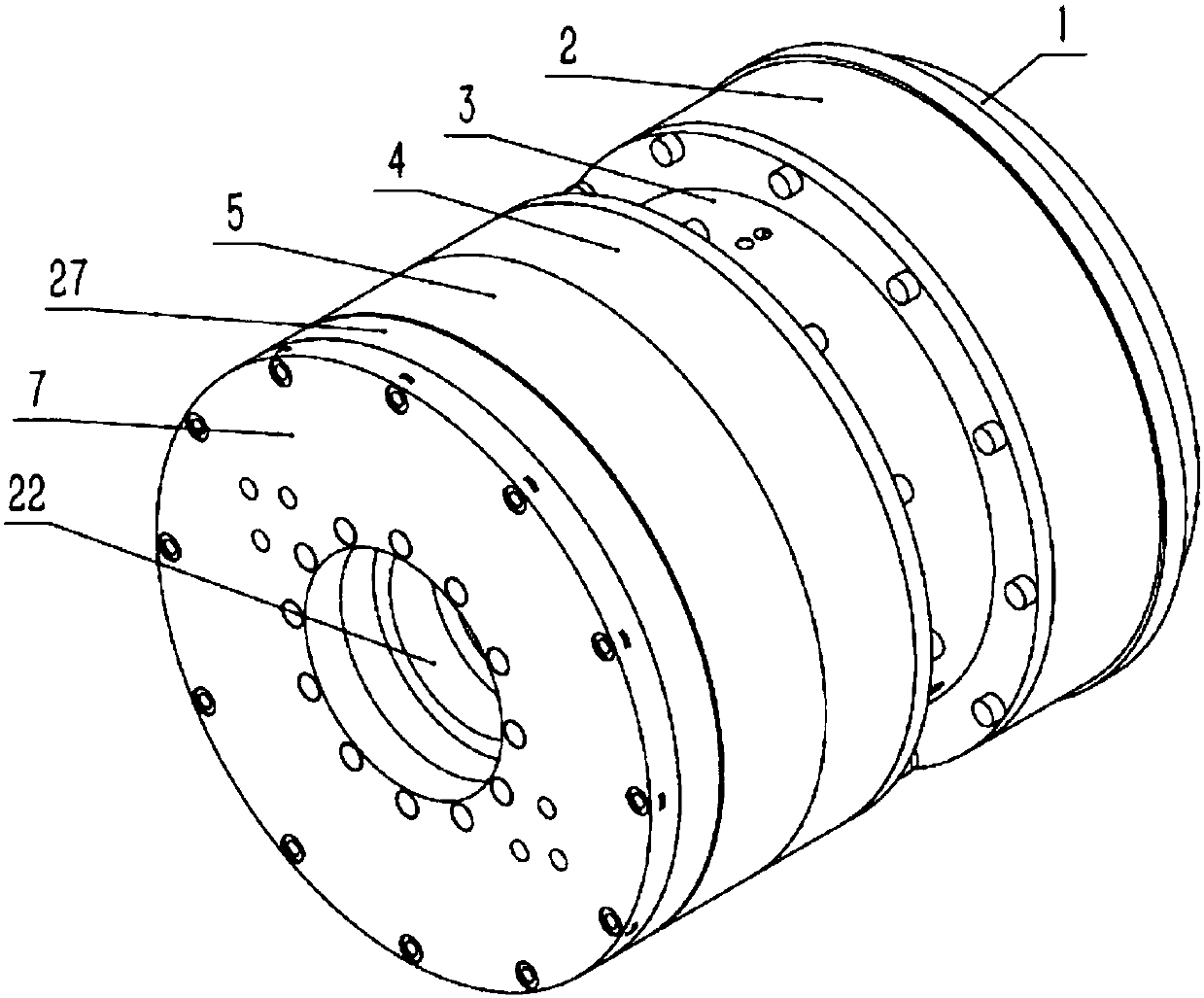

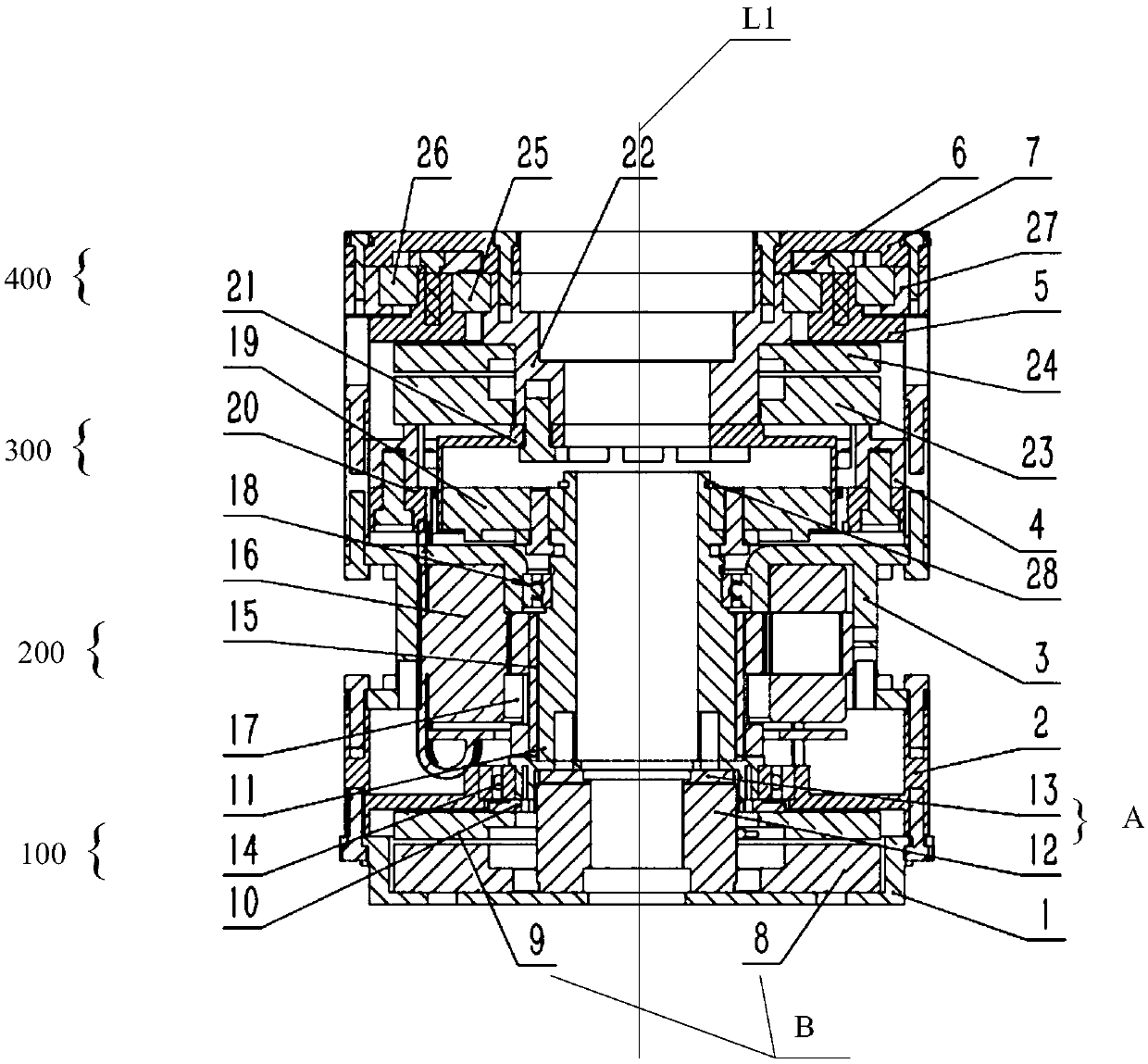

Mechanical arm and mechanical arm joint

A technology of robotic arms and joints, applied in the field of robot production, can solve the problems of not further improving the optimal arrangement of components in the joints, and not further improving the light and small characteristics of the joints, so as to reduce the volume and weight of the joints, compact structure, and high load. The effect of self-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0034] In this article, "first", "second", etc. are only used to distinguish each other, not to indicate the degree of importance and order, or the prerequisite for mutual existence.

[0035] Herein, "equal", "identical" and the like are not strictly restricted in the sense of mathematics and / or geometry, but also include errors understandable by those skilled in the art and allowed in manufacture or use. Unless otherwise stated, a numerical range herein includes not only the entire range within its two endpoints, but also several subranges subsumed therein.

[0036] In order to solve the problem in the prior art that the axial size of the joint is large due to the series arrangement of the internal parts of the joint, the present invention provides a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com