Lead wire arrangement structure capable of controlling direct current resistance unbalance

A technology of DC resistance and layout structure, applied in the field of transformers, can solve the problems of increasing material consumption and occupying space, increasing overall weight and volume, wasting space, etc., and achieving the effects of good control, improved operating performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

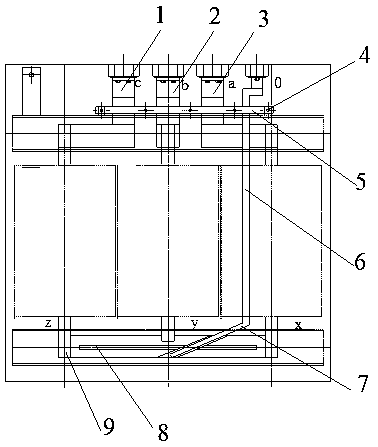

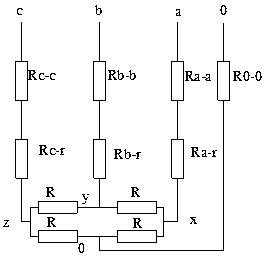

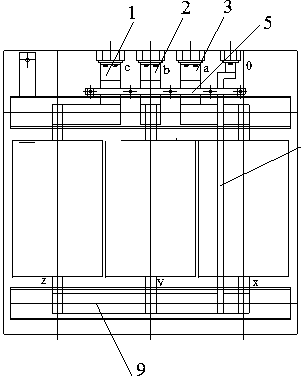

[0037] Such as figure 1 , figure 2 As shown, a lead arrangement structure for controlling DC resistance unbalance includes a head copper bar and a tail copper bar. The head copper bar includes a-phase copper bar 1, b-phase copper bar 2 and c-phase copper bar 3, and the tail The head copper bar is a low-voltage neutral point copper bar 9; a long strip-shaped notch 8 is set on the low-voltage neutral point copper bar 9, and the width of the notch 8 is greater than 8mm (if it is too narrow, it is easy to connect at the notch or leave solder ); the left end of the notch 8 does not reach the left end of the low-voltage neutral point copper bar 9, and the right end of the notch 8 does not reach the right end of the low-voltage neutral point copper bar 9.

[0038] Phase a line is drawn from phase a copper bar 1, and the end x of phase a line is welded to the left end of copper bar 9 of low-voltage neutral point; phase line b is drawn from phase b copper bar 2, and the end y of phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com