Glass bulb with cathode-ray tube and cathode-ray tube

A technology for cathode ray tubes and glass bubbles, applied in the direction of cathode ray tubes/electron beam tubes, cathode ray/electron beam tube shells/containers, discharge tubes, etc., can solve the problem that excessive thermal stress cannot be generated and insufficient reduction The weight of the funnel part, reducing the strength of the funnel part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

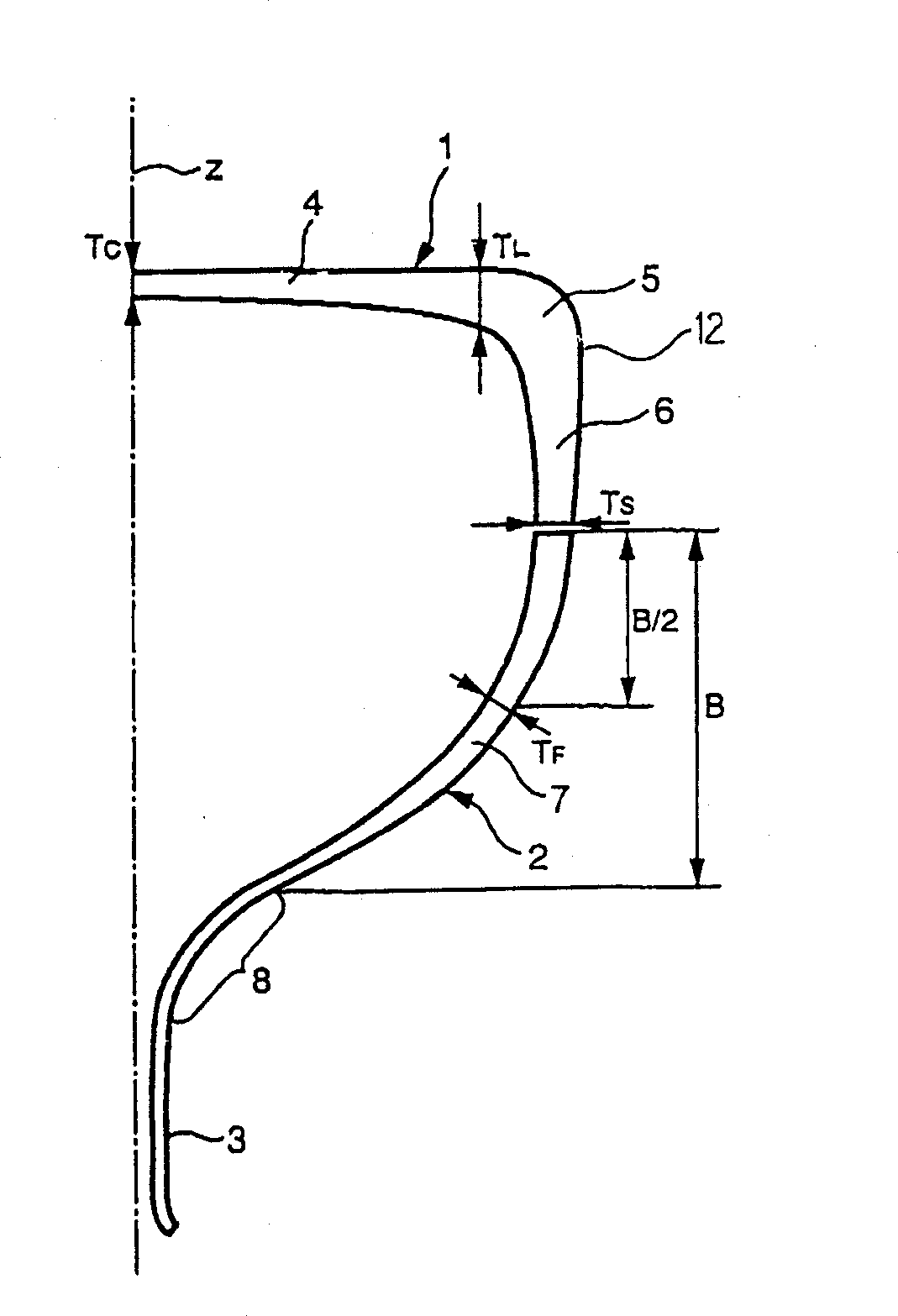

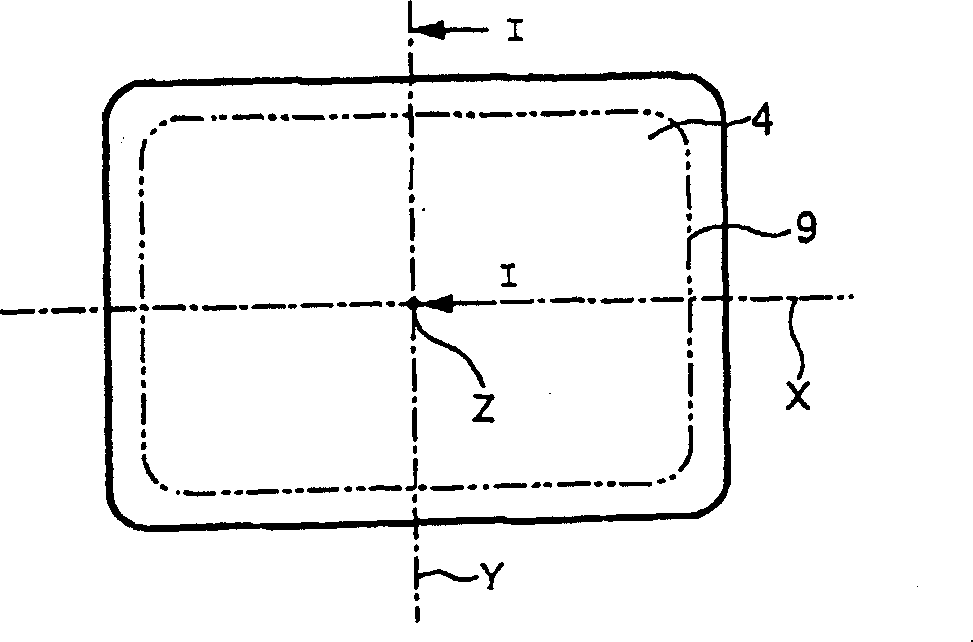

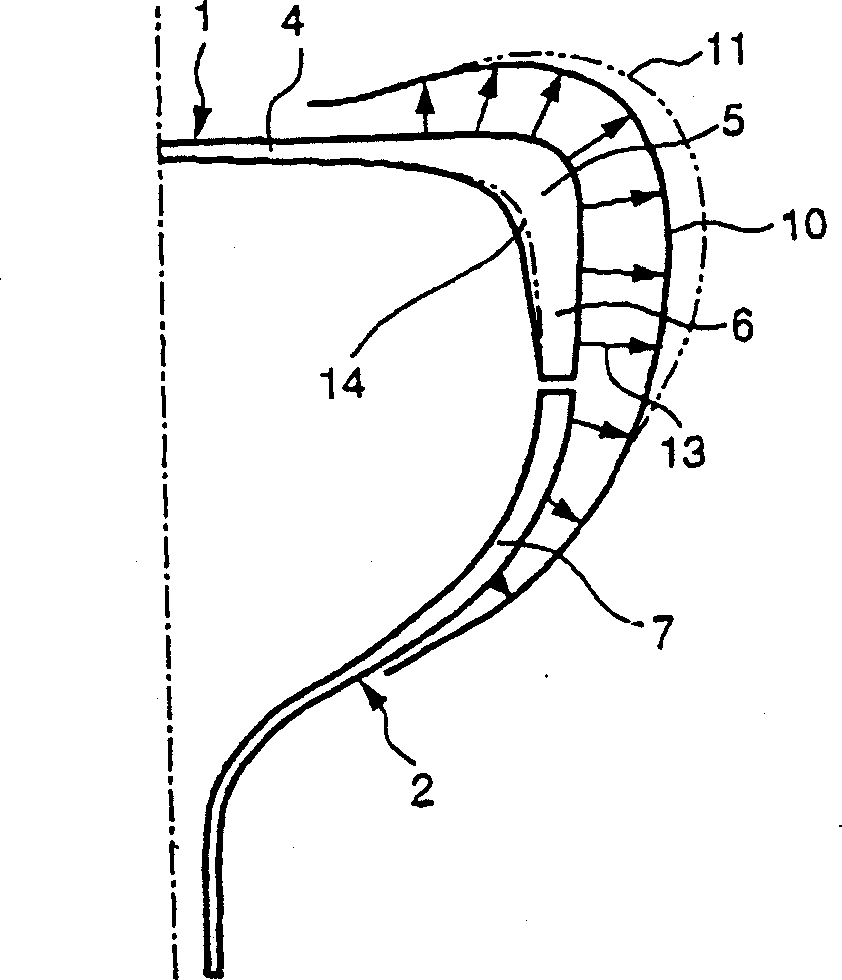

[0028] Now, the present invention will be specifically described with reference to the accompanying drawings. figure 1 is a partial sectional view of a glass bulb for a cathode ray tube of an embodiment of the present invention, figure 2 is a plan view of the panel portion; and figure 1 is along figure 2 A cross-sectional view taken along the line I-I. in other words, figure 1 The cross-sectional shape of the right half of the glass bubble taken along the short axis is shown. exist figure 2 In , the symbols X and Y denote the major axis and the minor axis of the surface part 4 respectively, and the dotted line 9 represents the useful screen area in the surface part 4 . In the glass bubble of this example, since the wall thickness of the end of the useful screen area in the surface portion 4 on the minor axis is greater than that of the end of the useful screen area on the major axis, the screen portion and funnel relative to the minor axis section fully defines the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com