Virtual vector optimizing and neutral-point potential balancing closed-loop control system of multilevel inverter

A multi-level inverter and potential balancing technology, applied to electrical components, AC power input conversion to DC power output, output power conversion devices, etc., can solve the unbalanced voltage division of the midpoint potential of the DC side voltage dividing capacitor Capacitance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

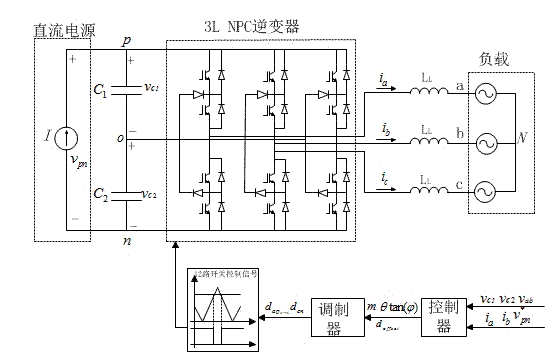

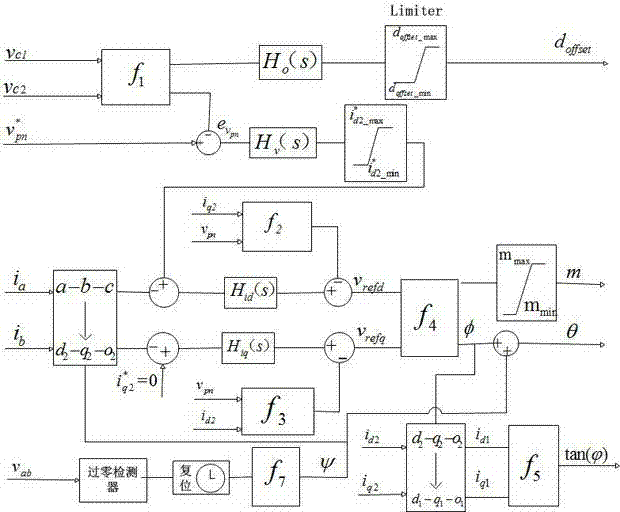

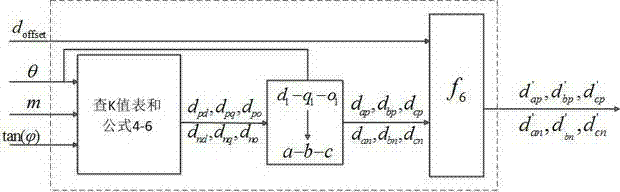

[0020] As shown in the figure, the multilevel inverter optimizes the virtual vector midpoint potential balance closed-loop control system:

[0021] Step 1. Signal conditioning: the three-phase voltage and current components of the inverter output terminal obtained by sensor sampling, and the voltage value of the DC side voltage dividing capacitor are filtered through the detection circuit to remove the disturbing glitch signal;

[0022] Step two, the design of the controller:

[0023] a. Find the amount of compensation : Input the signal obtained in step 1 into the DSP for A / D conversion, and after digital quantization, the voltage of the dividing capacitor To process, get the offset of the midpoint potential respectively and DC side bus voltage value , and the offset is compensated by a low-pass compensator , and by and compare the amount of error , after the processing of the compensator, we can get expectations ;

[0024] b. Reference voltage vector angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com