Cell automatic detection device and application of go-gauge component in cell detection device

A technology of automatic detection device and battery cell, which is applied to measurement devices, measurement gauges, and optical devices, etc., can solve the problems of limited detection data, low accuracy and efficiency of detection institutions, and ensure wide applicability and integrity. the effect of avoiding detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

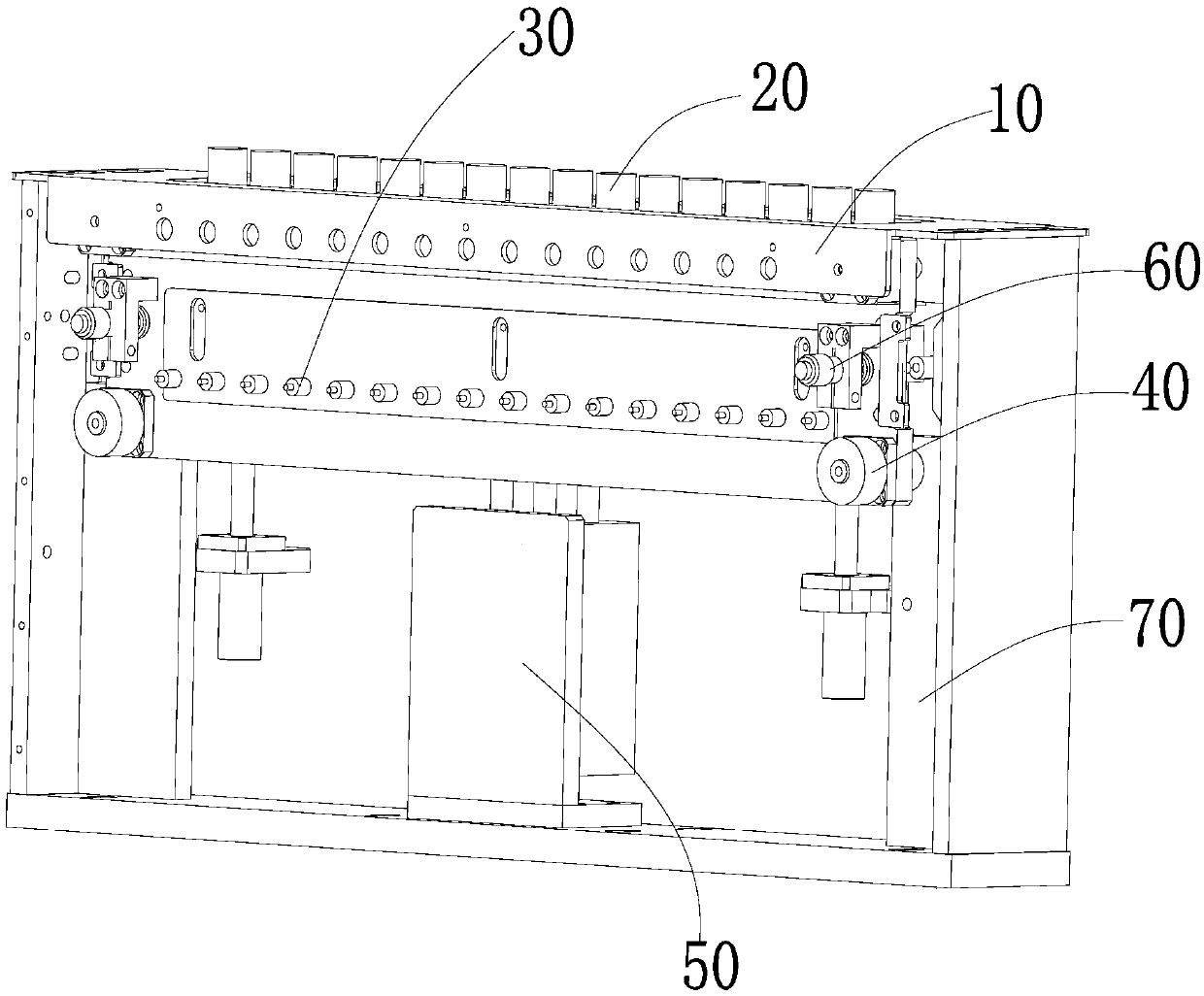

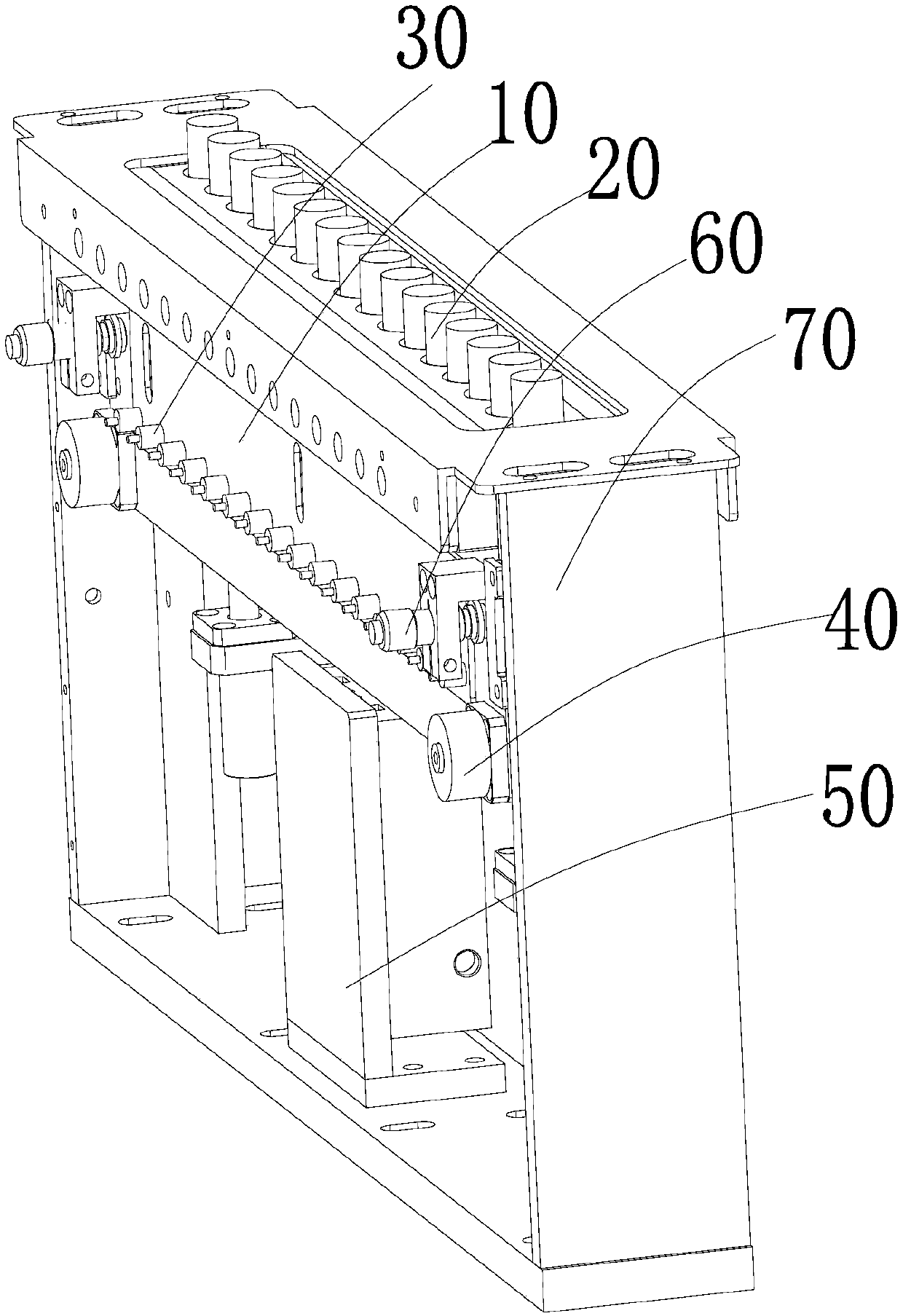

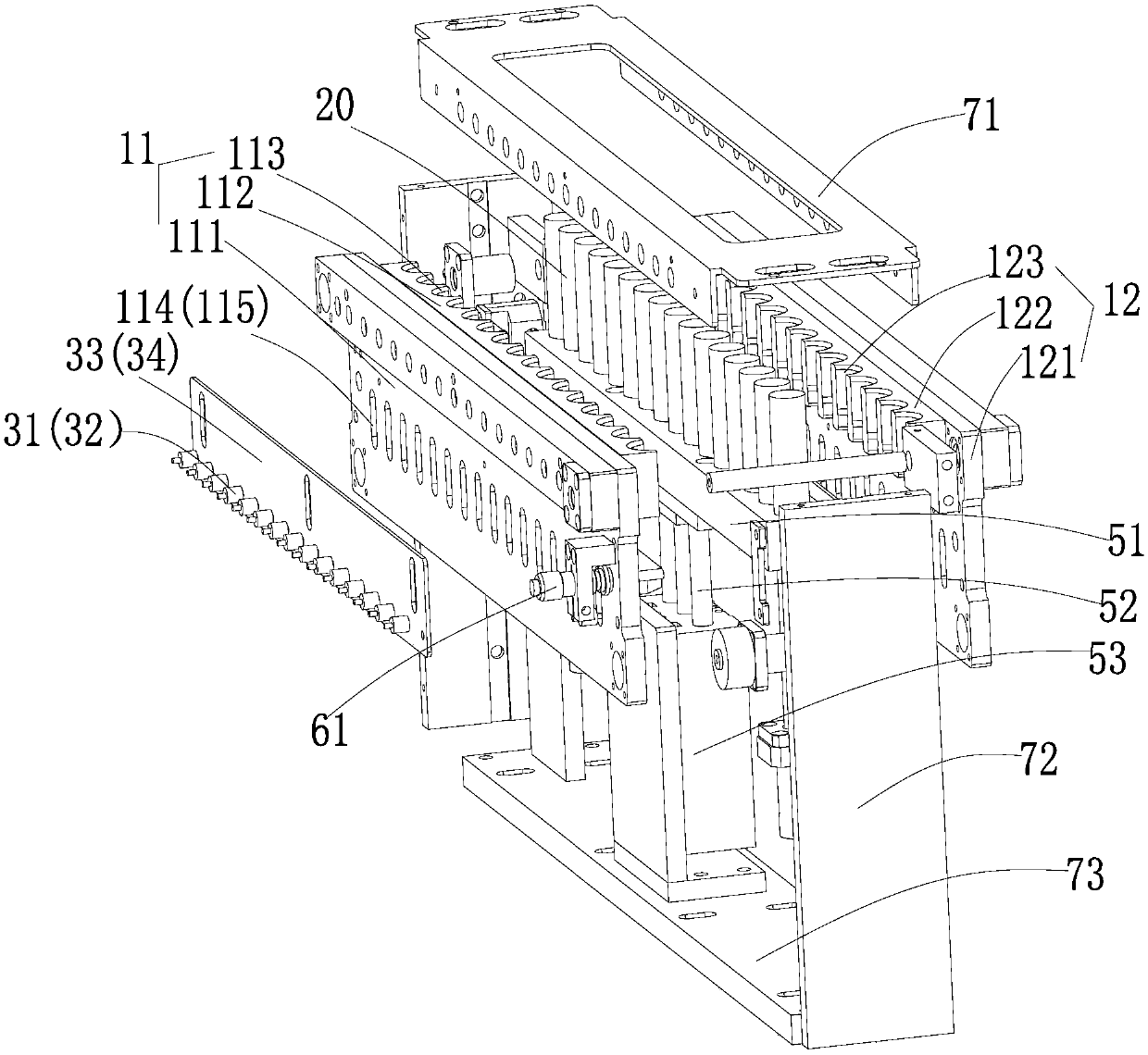

[0027] Please refer to the attached Figure 1 to Figure 4 As shown, in the embodiment of the present invention, an automatic battery detection device is provided, including a pass gauge assembly 10, a first drive assembly 40 connected to the pass gauge assembly 10, a photosensitive assembly 30 connected to the pass gauge assembly 10 And the second drive assembly 50 connected to the pass gauge assembly 10, and the adjustment assembly 60 connected to the pass gauge assembly 10. The general gauge assembly 10 is used to clamp several battery cells 20 , preferably multiple here, that is, simultaneous detection of multiple battery cells 20 can be realized. The first driving assembly 40 is used to drive the general gauge assembly 10 to clamp or loosen the battery cell 20 , so as to realize the clamping and unloading of the battery cell 20 . The photosensitive component 30 is preferably fixedly connected to the side of the through gauge component 10, and the light output direction of...

Embodiment 2

[0048] An application of a general-gauge assembly in an automatic battery detection device, comprising a general-gauge assembly for clamping several battery cells, and the passage limit of the battery cells is limited by the general-gauge assembly. By driving the battery cell to move up and down in the general gauge assembly, the outer diameter detection of the full battery cell is realized. The general gauge detection technology is applied in the field of battery testing, especially in the detection of the battery outer diameter, which not only realizes the outer diameter of the full battery cell The detection method is simple, strong in implementability, not affected by external factors, high in detection accuracy, strong in stability, and low in cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com